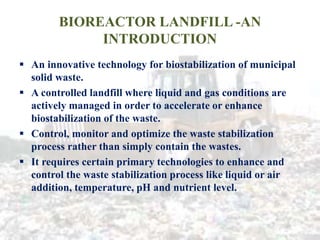

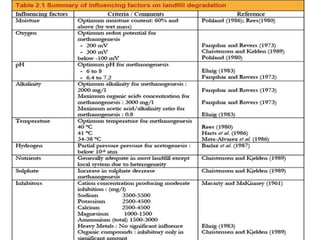

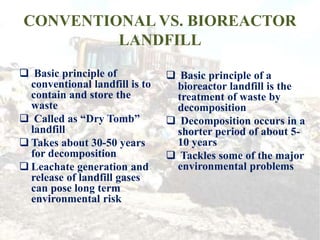

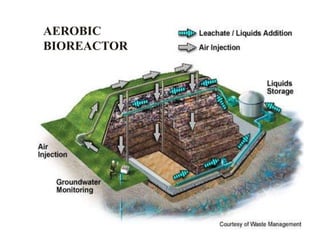

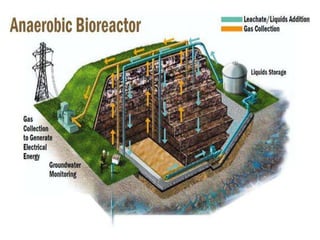

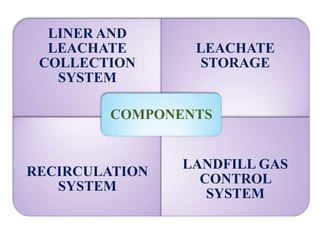

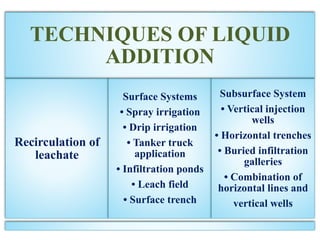

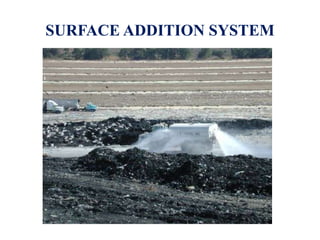

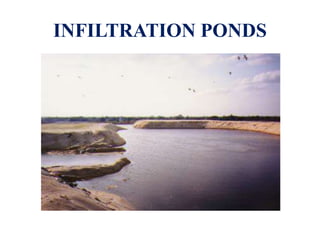

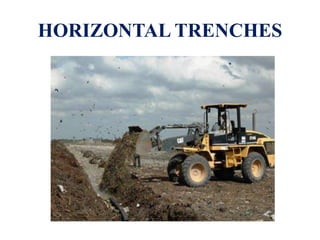

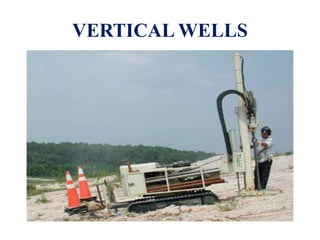

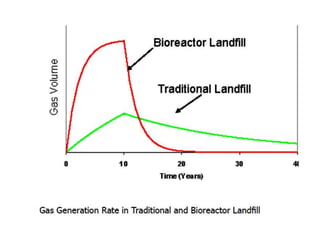

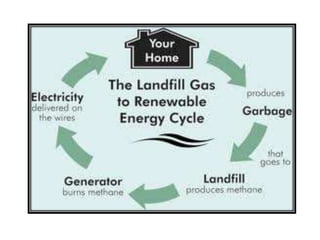

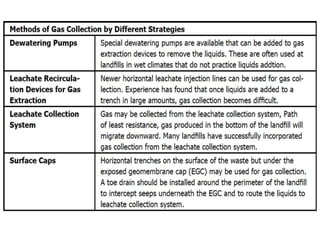

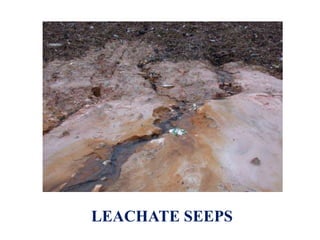

This document provides an introduction to bioreactor landfills. It discusses that bioreactor landfills actively manage liquid and gas conditions to accelerate waste stabilization compared to conventional landfills. There are three main types - aerobic, anaerobic, and hybrid bioreactor landfills. Bioreactor landfills require technologies like liquid or air addition to control waste stabilization processes. They can stabilize waste in 5-10 years compared to 30-50 years for conventional landfills. Monitoring categories include leachate, landfill gas, and waste characteristics to optimize the waste stabilization process.