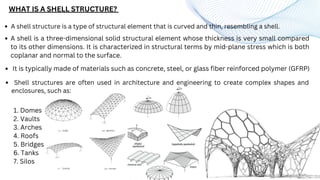

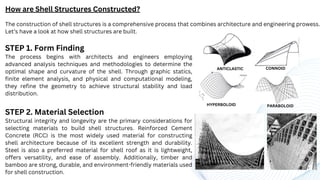

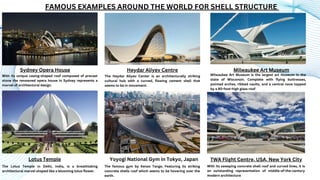

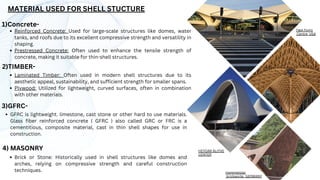

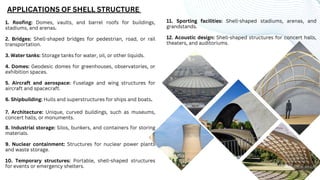

A shell structure is a curved, thin structural element used in architecture and engineering, characterized by its small thickness compared to other dimensions. The document outlines the process of designing, constructing, and materials used for shell structures, highlighting their applications and examples globally, such as the Sydney Opera House and the Lotus Temple. The advantages include aesthetic appeal and resistance to natural disasters, while challenges include complexity in design and high construction costs.