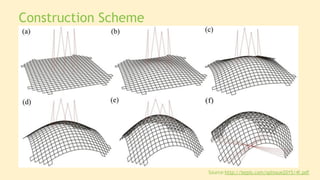

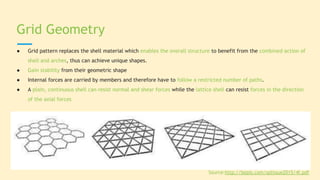

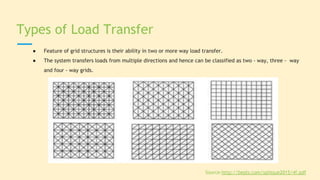

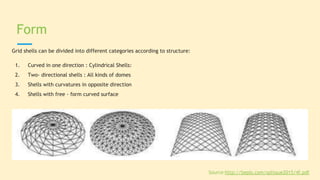

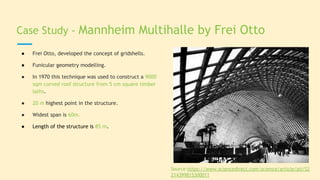

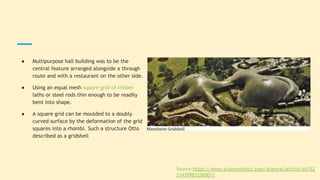

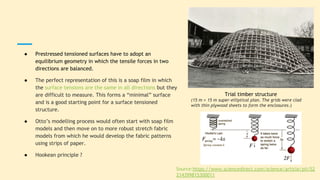

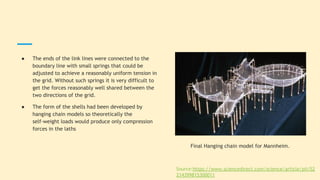

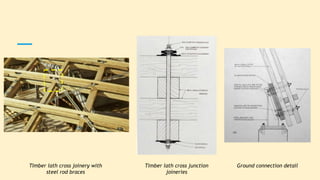

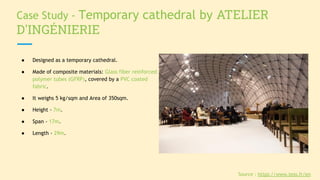

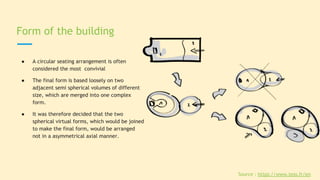

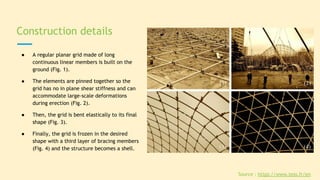

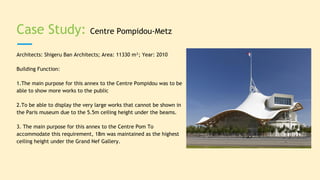

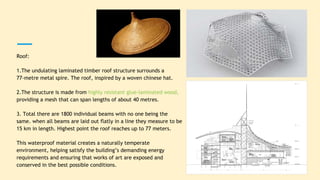

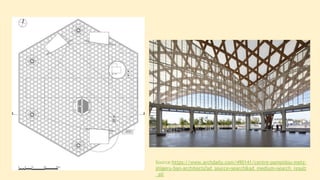

Grid shells are three dimensional structures that resist loads through their geometric shape without requiring additional frames or columns. They are made of interconnected members arranged in triangular, square or hexagonal patterns to form vaulted surfaces. Key advantages are their ability to create unique curved shapes with few internal supports, using less material than conventional structures. The document discusses the Mannheim Multihalle by Frei Otto as an early prominent example, built in 1970 out of timber laths formed into a funicular grid shell surface. Construction details are provided on forming the curved surface by adjusting tensions in a physical model. Other case studies described are a temporary composite grid shell cathedral and the Centre Pompidou-Metz with its distinctive undulating wooden roof structure