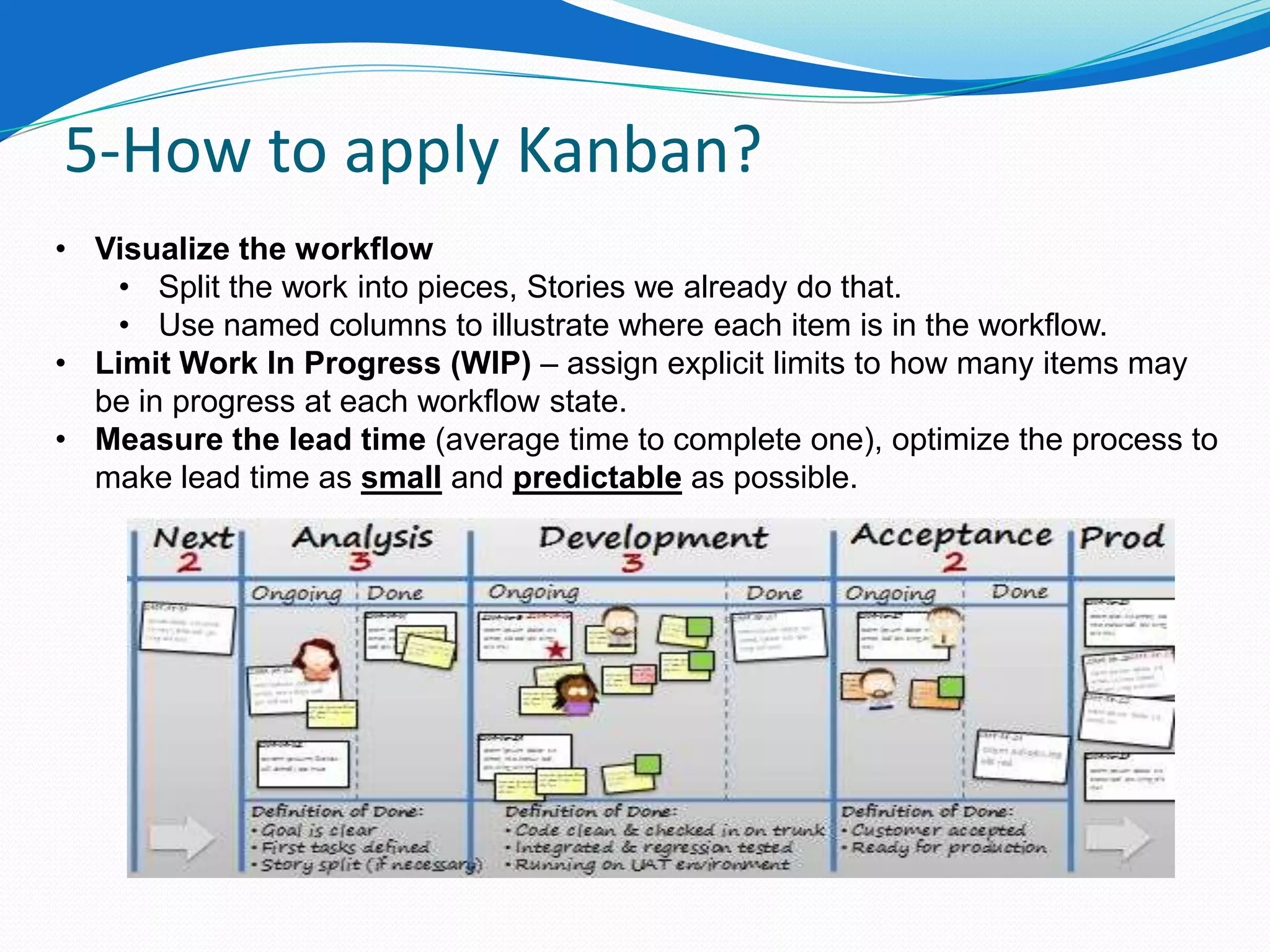

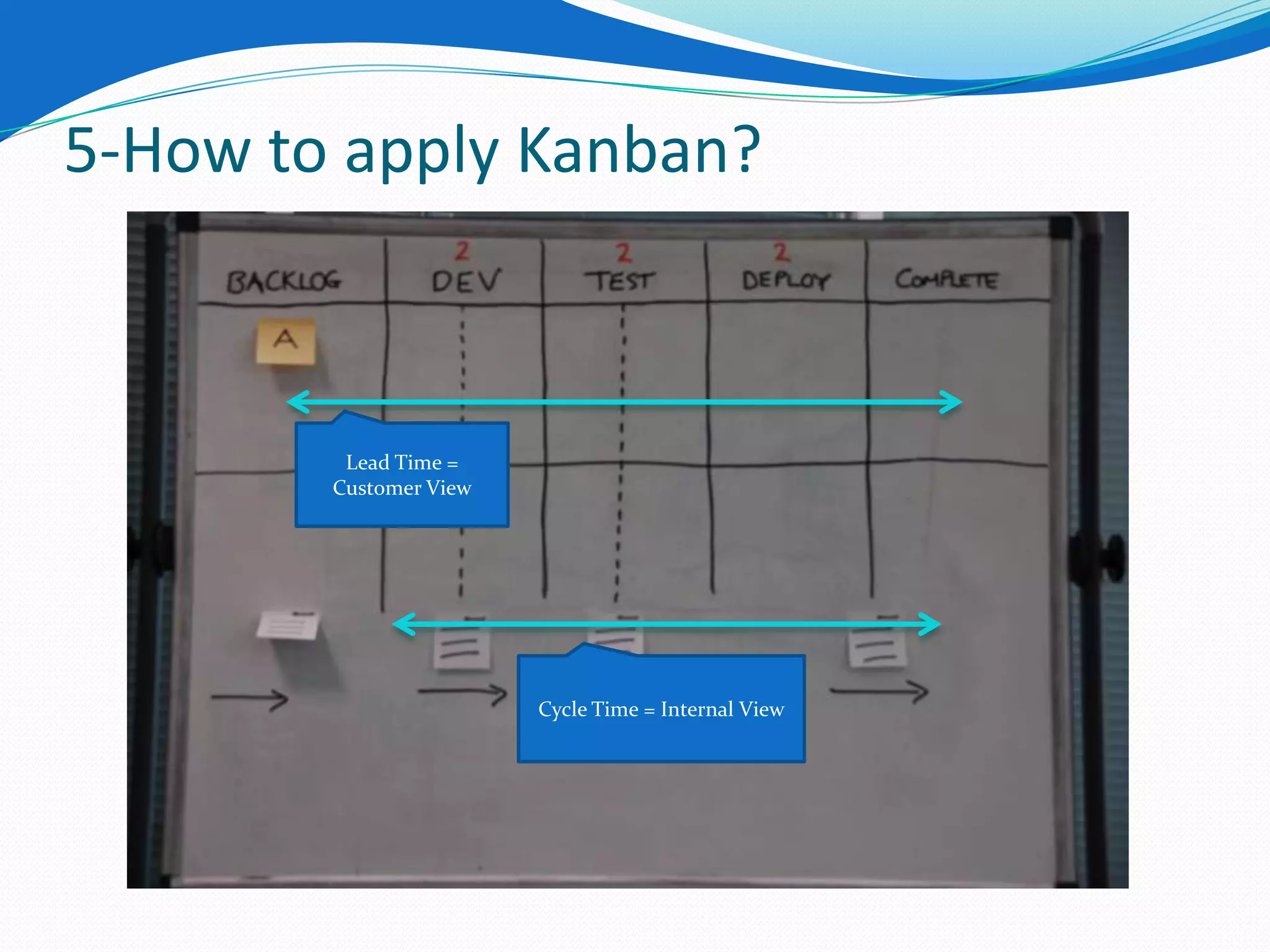

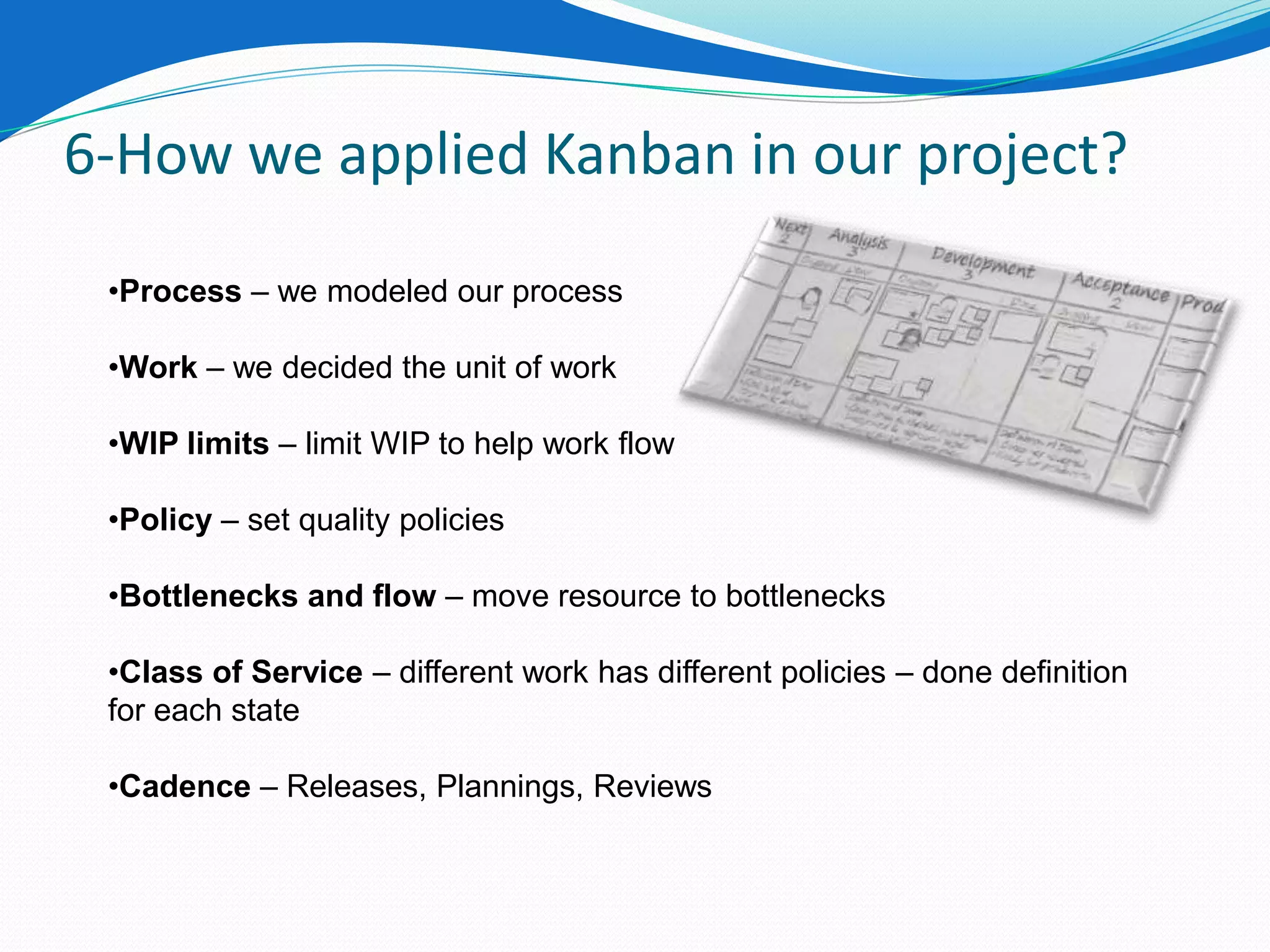

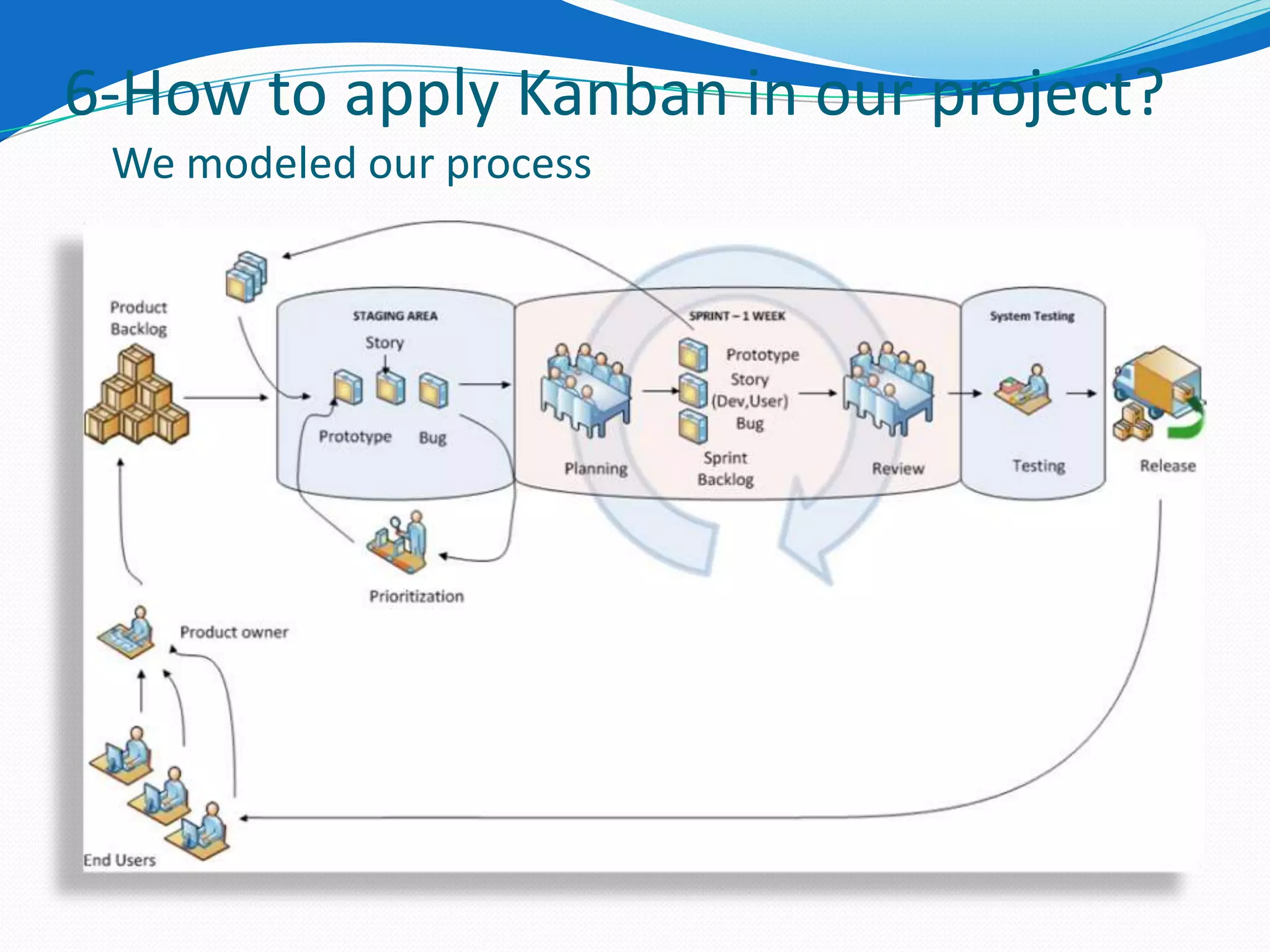

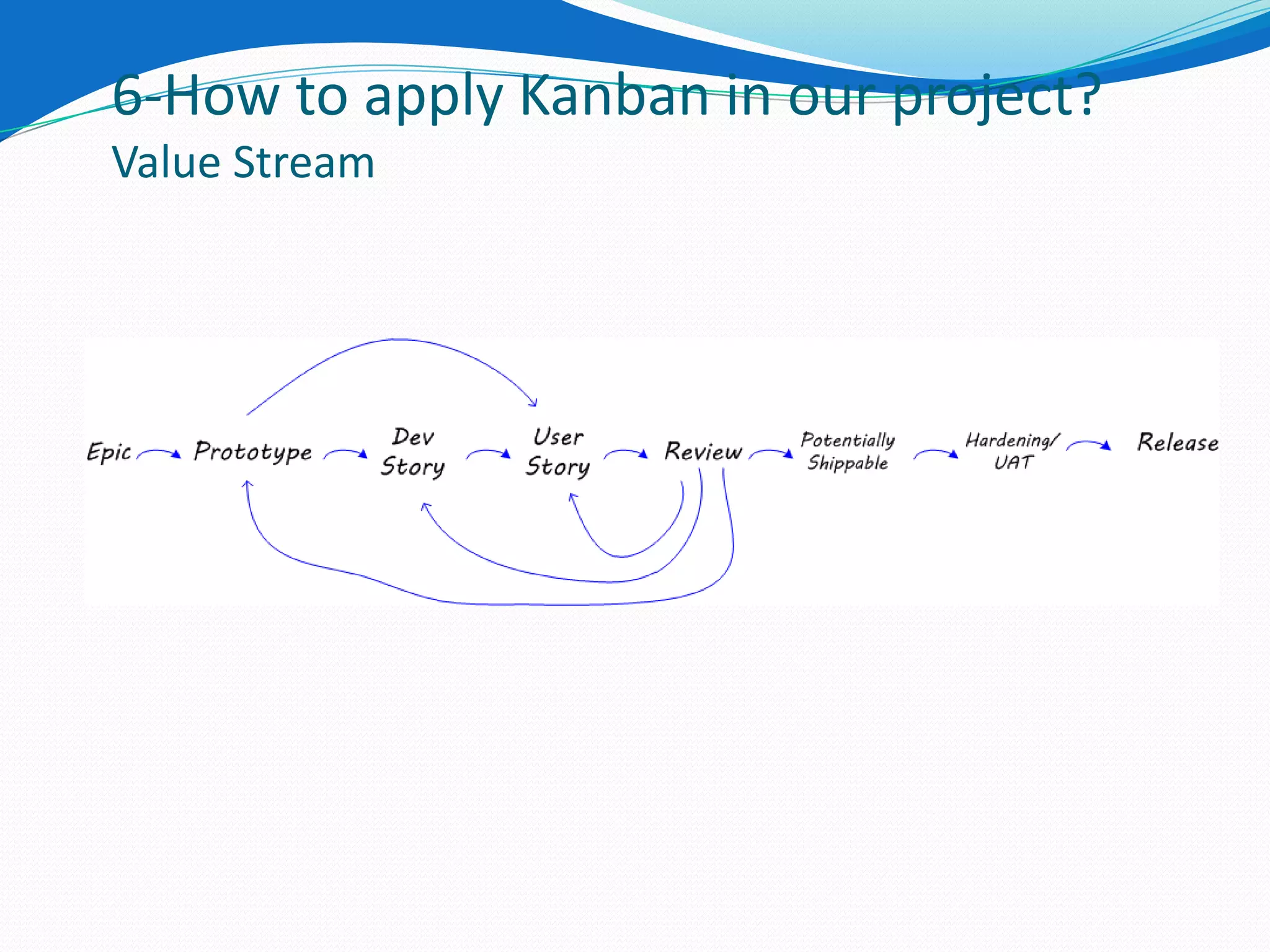

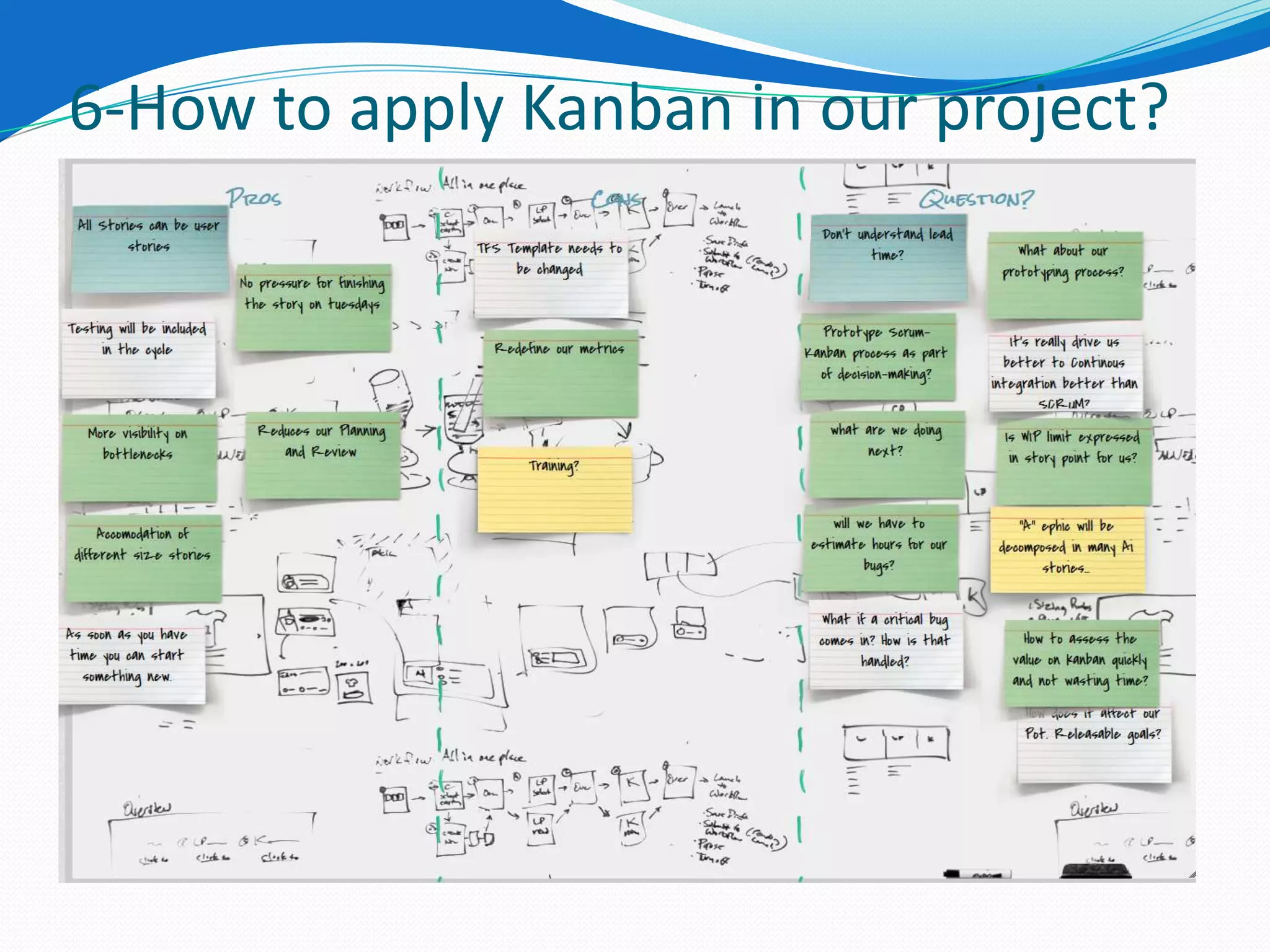

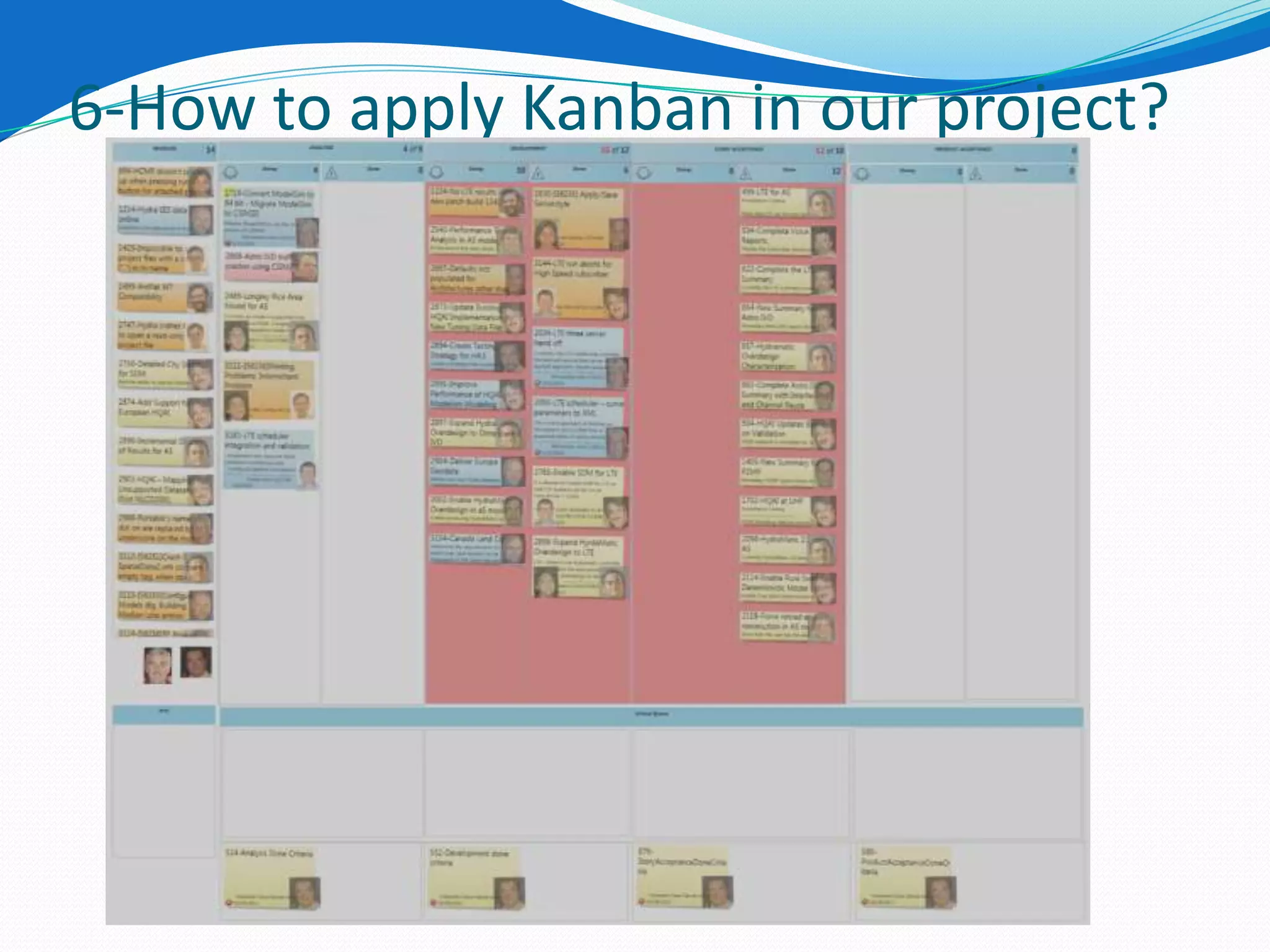

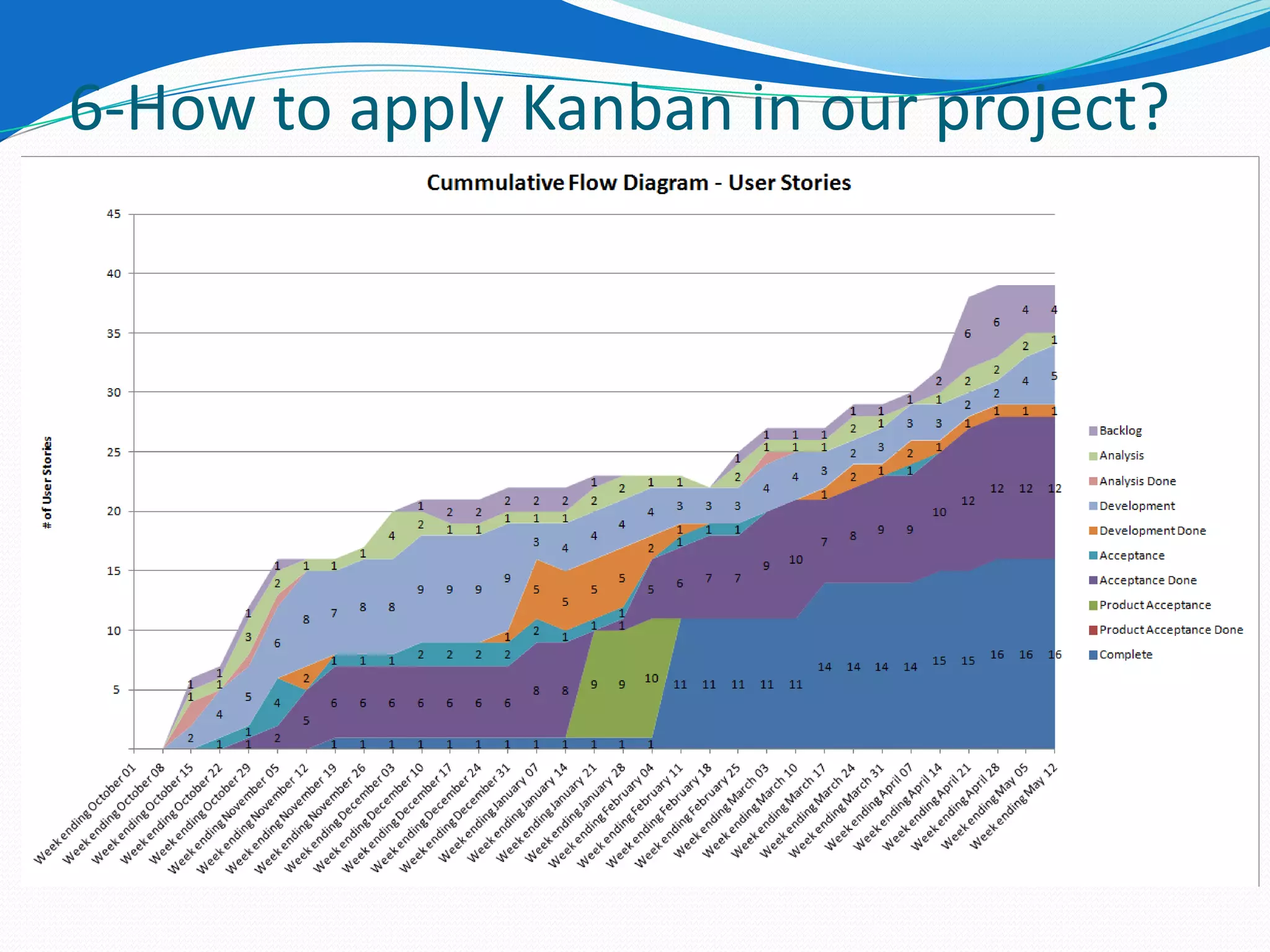

This document discusses the experience of applying Kanban principles to software development at a company with 14 team members split between two locations. Previously using Scrum, the team transitioned to Kanban 6 months ago using a tool to visualize work in progress. Benefits included improved workflow visibility, reduced bottlenecks, and higher quality work through clearer definitions of work states. Release lead times decreased from an average of 90 to 60 days. Some challenges remain around long-term visibility but overall the Kanban approach helped improve productivity and quality.