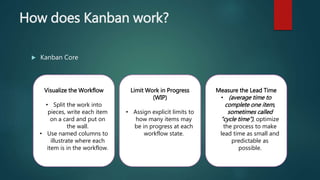

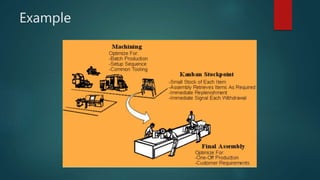

Kanban is an agile development methodology originating from a Japanese term meaning 'visual card,' utilized by Toyota as part of its lean production system. It emphasizes visualizing workflow, limiting work in progress, and optimizing lead time to increase efficiency and respond quickly to customer demand. Key benefits include reduced inventory, improved workflow, enhanced collaboration, and better responsiveness to market changes.