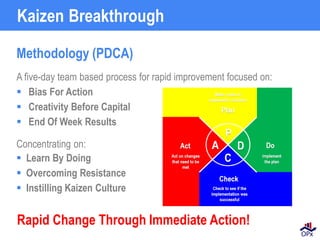

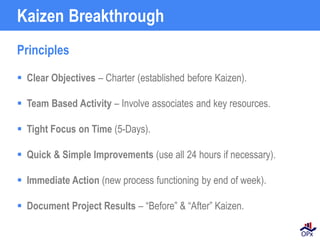

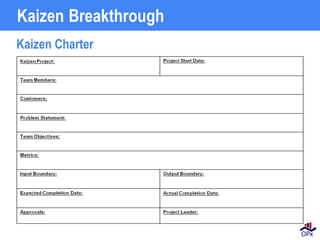

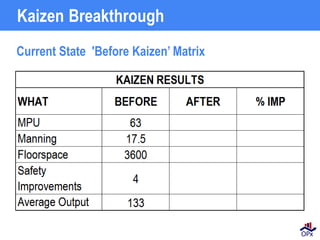

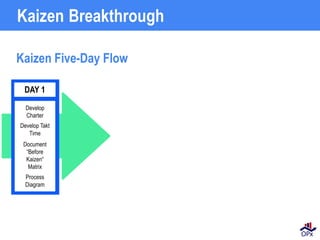

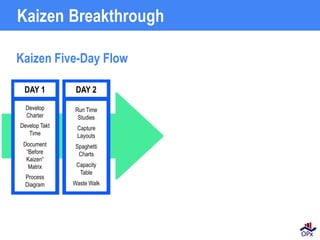

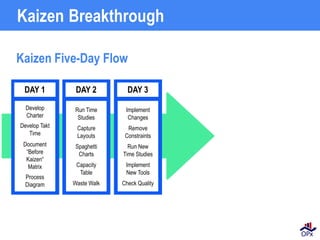

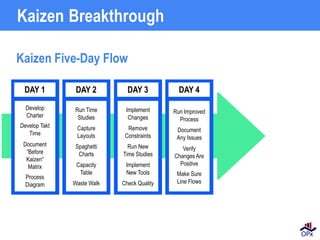

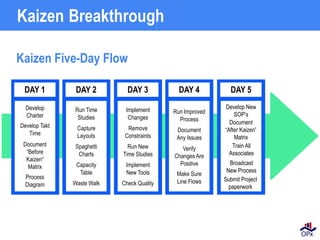

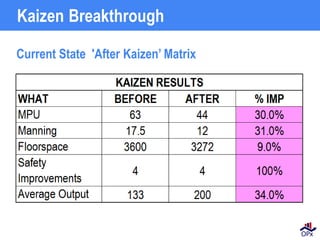

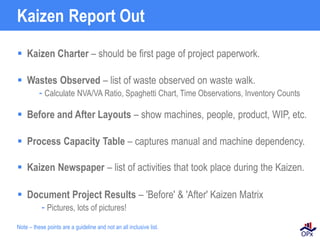

Kaizen Breakthrough is a five-day team-based process for rapid improvement focused on bias for action, creativity before capital, and achieving end-of-week results. The process follows the PDCA methodology and concentrates on learning by doing, overcoming resistance, and instilling a Kaizen culture. Key principles include establishing clear objectives and a charter before starting, involving associates and key resources, focusing tightly on the five-day timeframe, implementing quick and simple improvements, achieving immediate action with a new functioning process by the end of the week, and documenting results. Each day of the five-day flow has specific activities, such as developing the charter, running time studies, implementing changes, verifying improvements, and documenting the