The document discusses the implementation of Kaizen principles in the Ethiopian TVET (Technical and Vocational Education and Training) system, detailing its importance for organizational performance and continuous improvement in various sectors. It traces the origins of Kaizen from Japanese management practices, emphasizing training and practical applications tailored to Ethiopian enterprises, particularly in enhancing productivity with minimal investment. Key components of the Kaizen methodology, like the 5S system, are also highlighted, alongside the efforts of the Ethiopian Kaizen Institute to facilitate training and application across industries.

![15

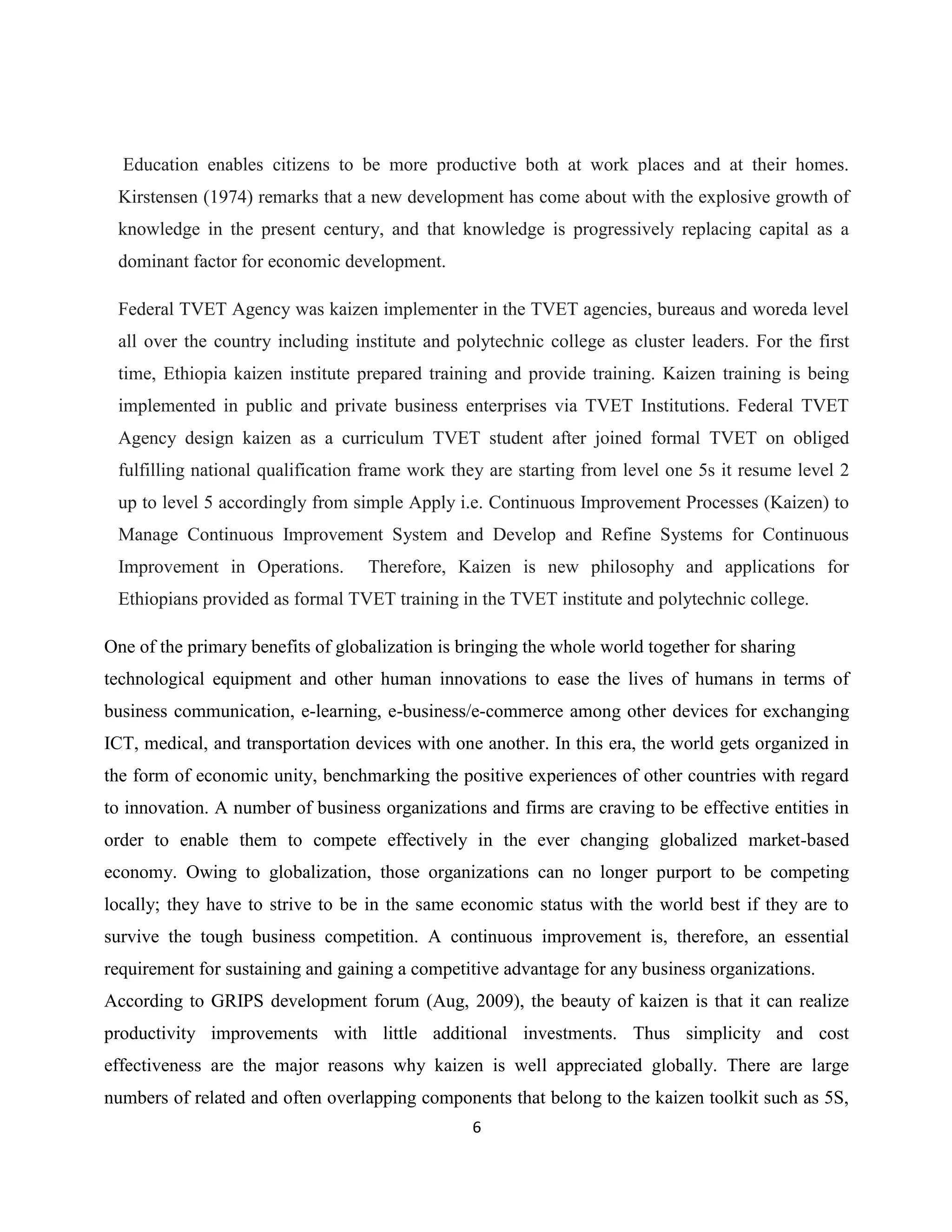

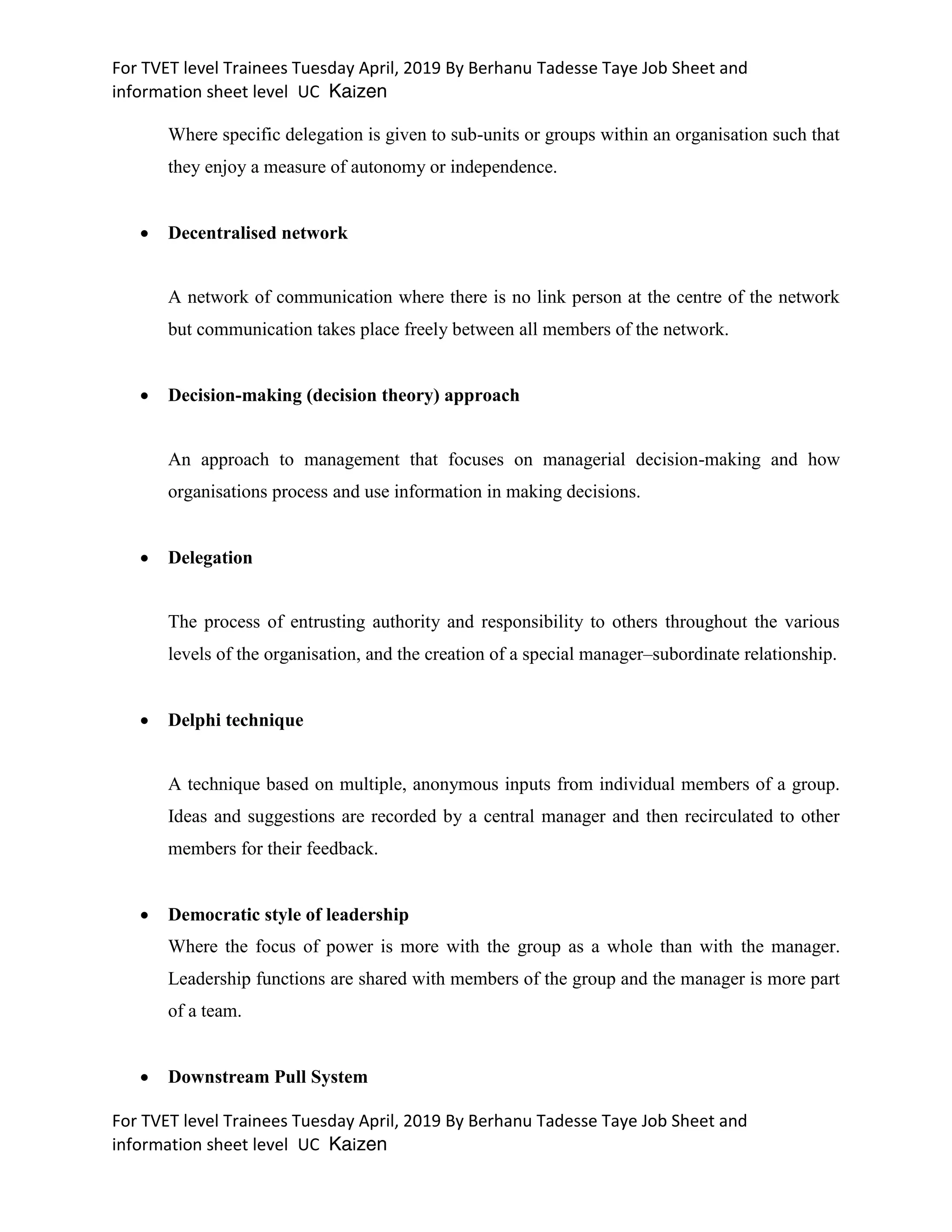

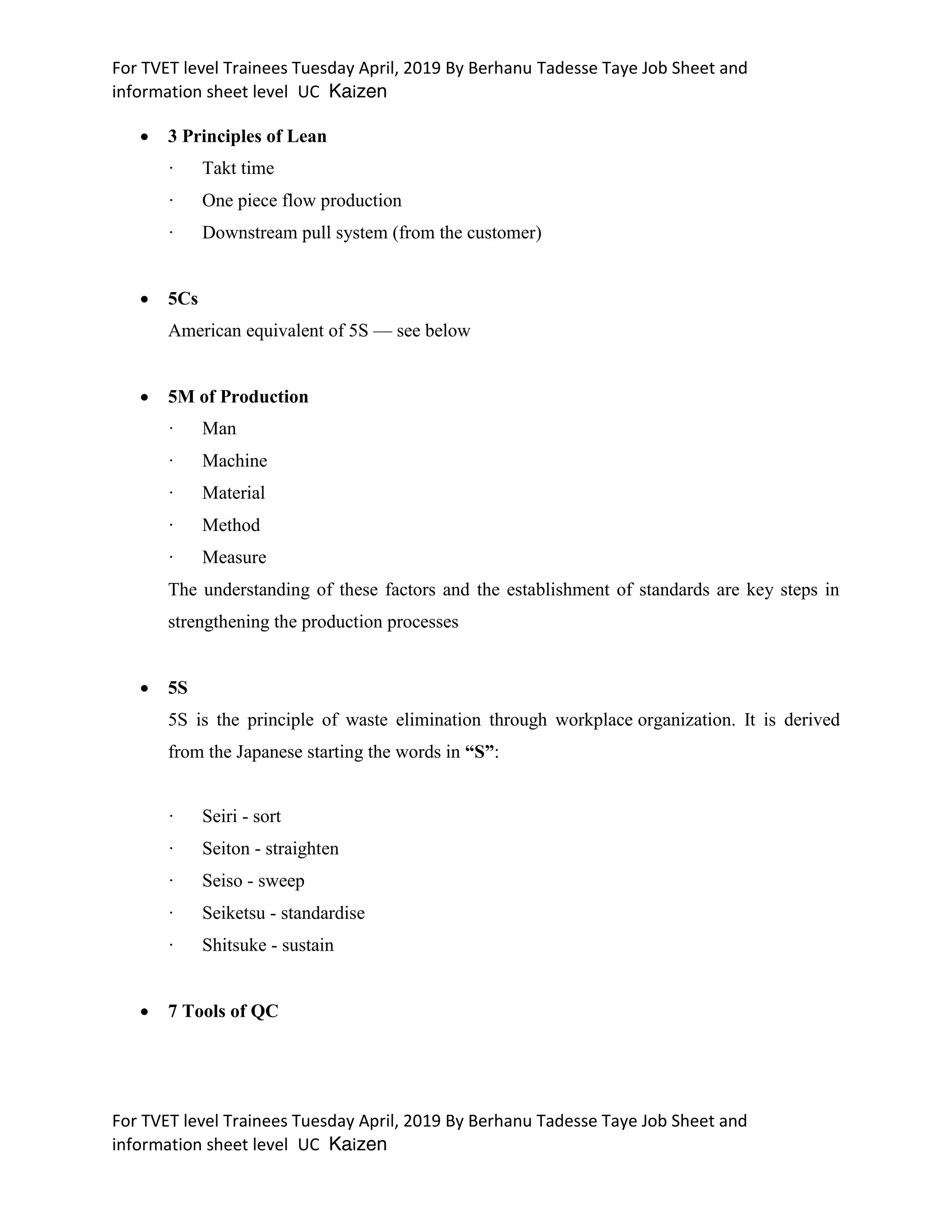

a process-orientation approach to organizational analysis centered around a horizontal review of all

activities involved in the process, or set of activities, in the delivery of a product or service to the

customer. BPR is concerned with the total restructuring of the organization. It starts from how one

would like the organization to be and works backward in an effort to achieve real gains in

organizational performance and delivery of products or services.

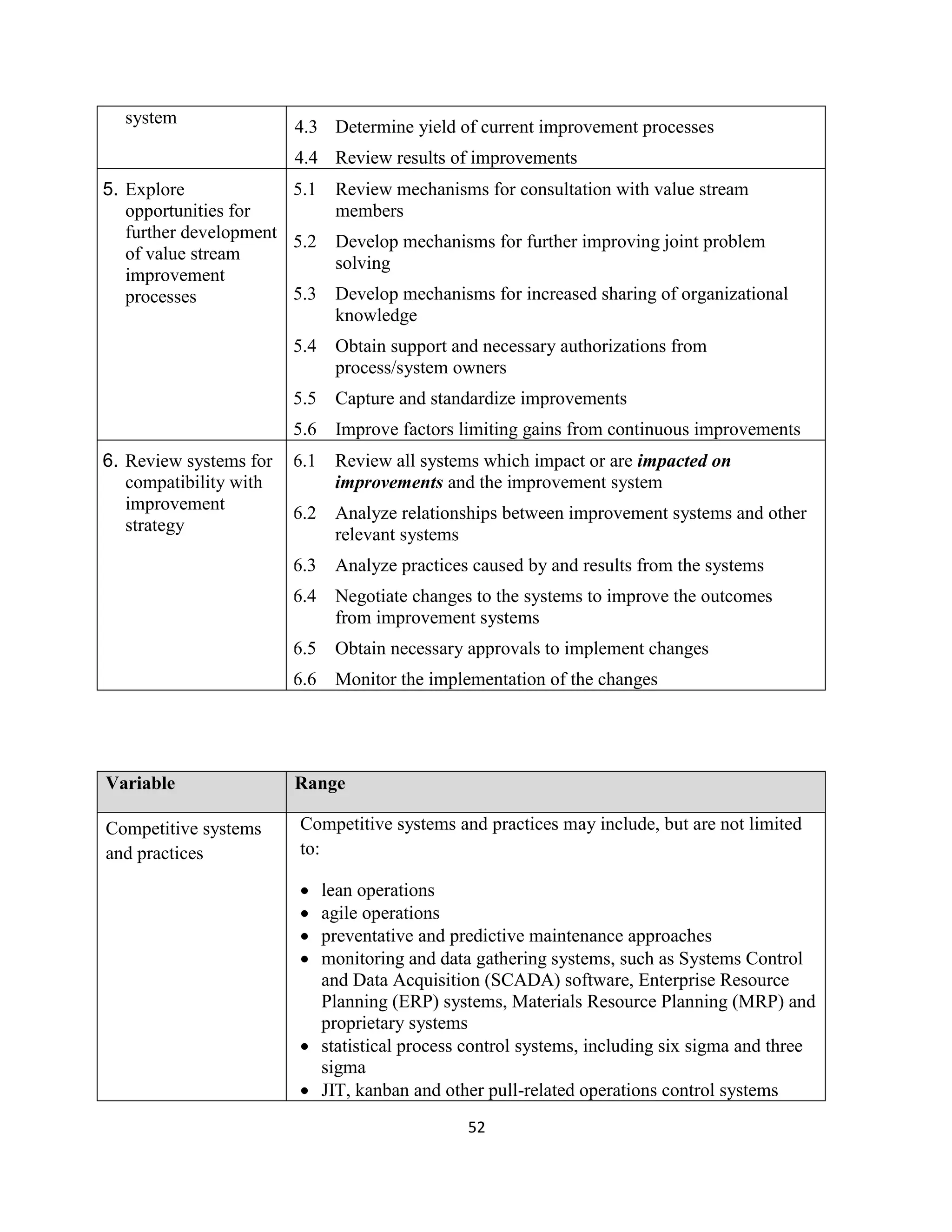

1.3.4.3 Relationship with TQM

What is the relationship between BPR and TQM? Both are concerned with organizational

processes that lead to customer satisfaction. However, while TQM tends to seek continuous

incremental improvement within a specific framework, BPR seeks major advances in performance

from a horizontal, cross-functional anatomy of performance perspective. It involves a challenge to

traditional structure, relationships, boundaries or barriers. TQM requires a supportive environment

and relies on teamwork, participation and commitment BPR takes a more strategic approach and

needs to be driven, at least initially, by top management. Some commentators appear to suggest

that TQM has been taken over by BPR although others argue that it can be seen as complementary

to and/or a forerunner for BPR.

1.3.4.4 Kaizen and Re-Engineering

The aim is to do what we already do, only to do it better. Quality improvement seeks steady

incremental improvement to process performance. Reengineering, as we have seen, seeks

breakthroughs, not by enhancing existing processes, but by discarding them and replacing them

with entirely new ones. (Michael Hammer and James Champy, Reengineering the Corporation: A

Manifesto for Business Revolution [New York: HarperBusiness, 1993], 49.) The logic of kaizen is

that breakthroughs result not from massive reorganizations or large-scale investment projects but

from the cumulative effects of successive incremental improvements. "Rebuilding a factory," wrote

William H. Davidow and Michael S. Malone (The Virtual Corporation [New York: Harper

Business, 1992], 118), "requires replacing almost every brick in the old plant. Do that too quickly

and the structure will collapse. The only practical way is through kaizen."](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-15-2048.jpg)

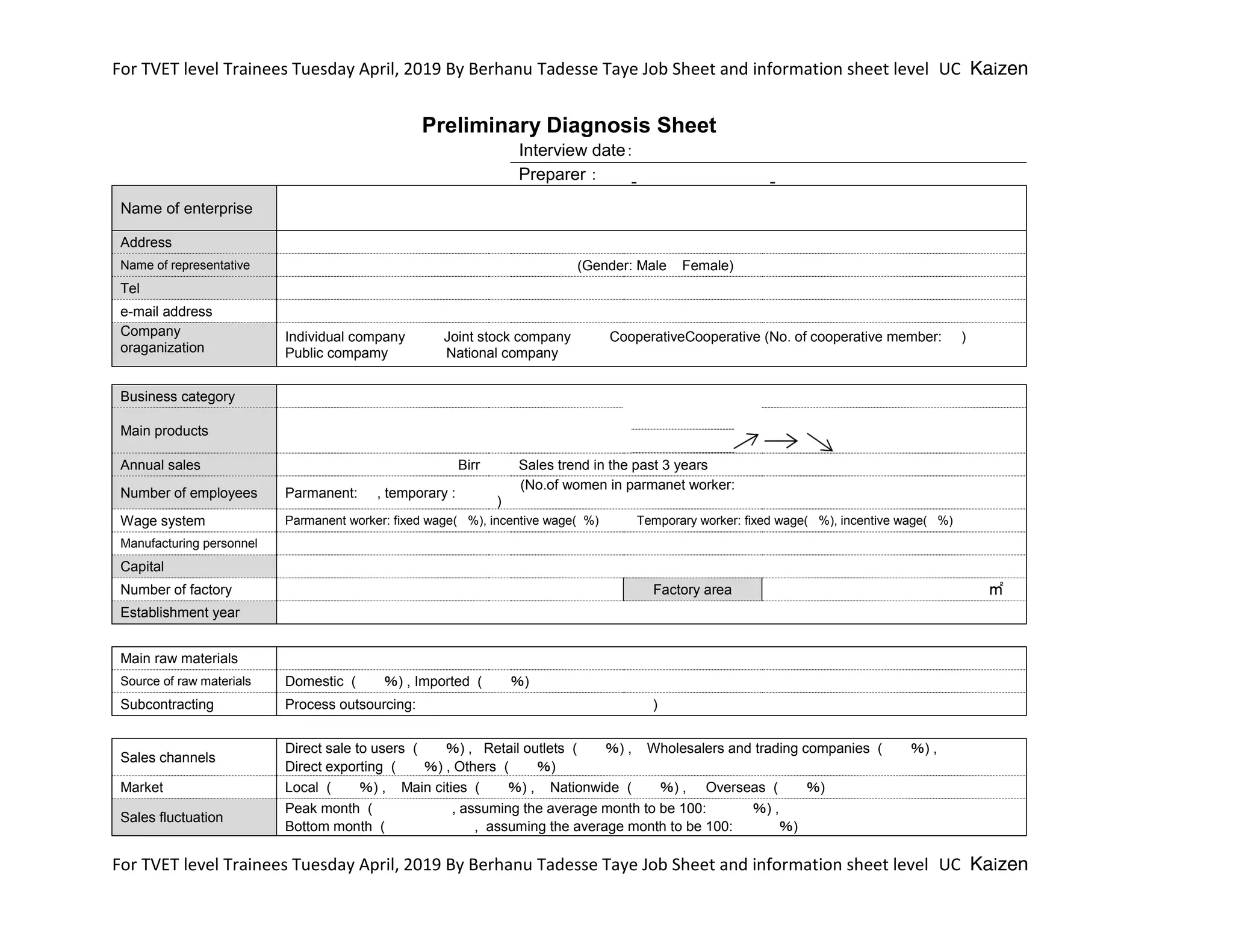

![[ T y p e t h e c o m p a n y a d d r e s s ]

Chapter Two Summary

From this reference book, there is very scanty information on Kaizen implementation and

accruing benefits especially concerning promotion of organization effectiveness in any

organization. How to use kaizen from level one to application to managing kaizen as level V

curriculum as a modular approach?

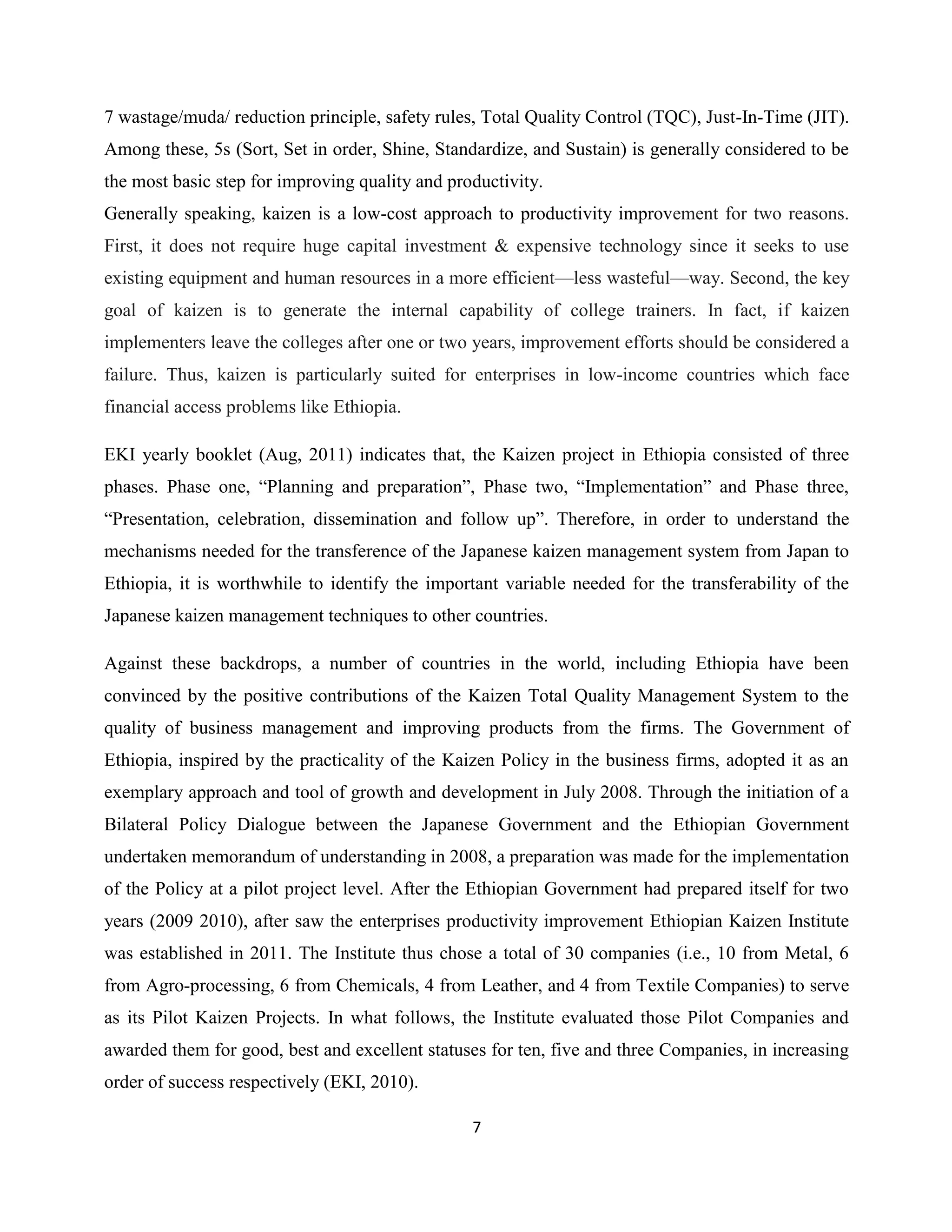

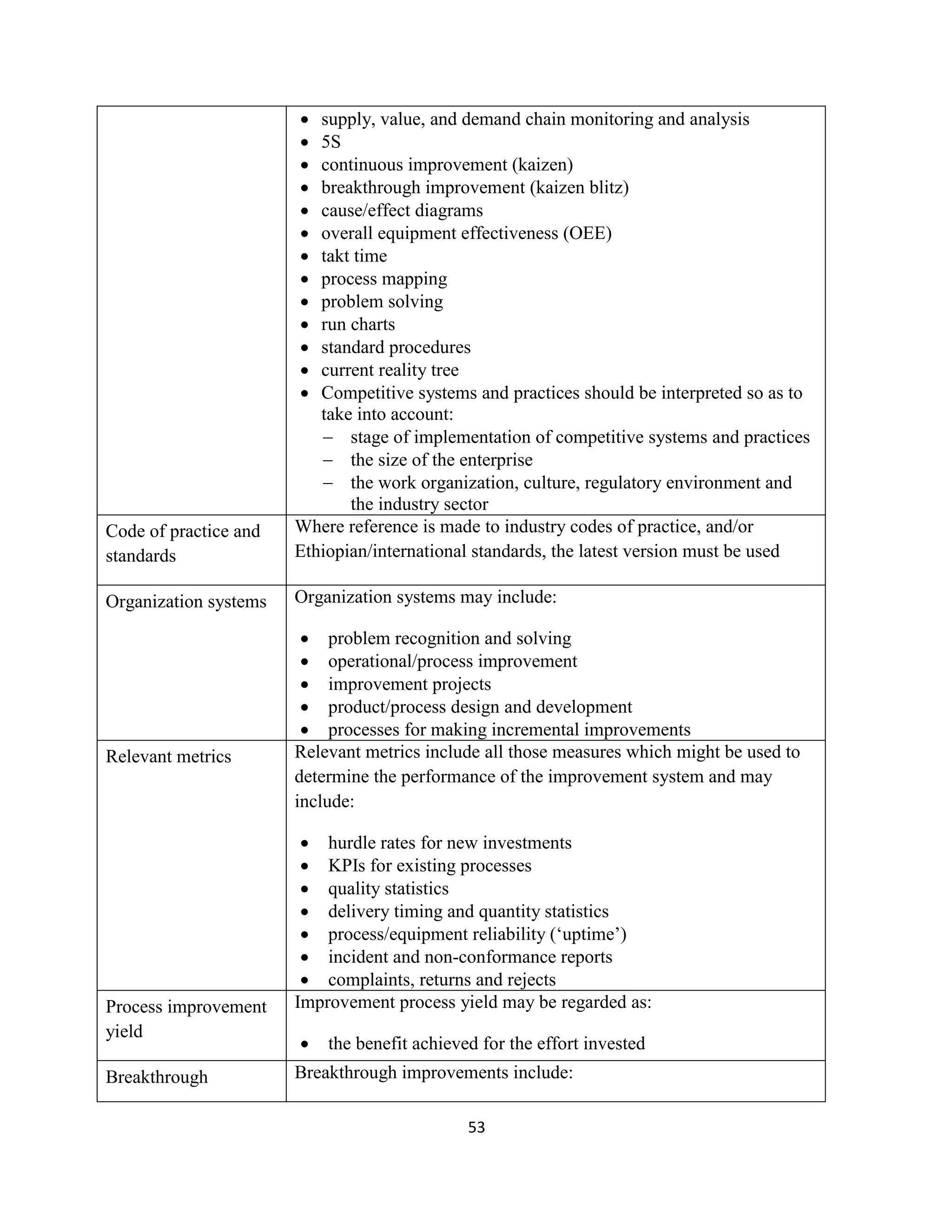

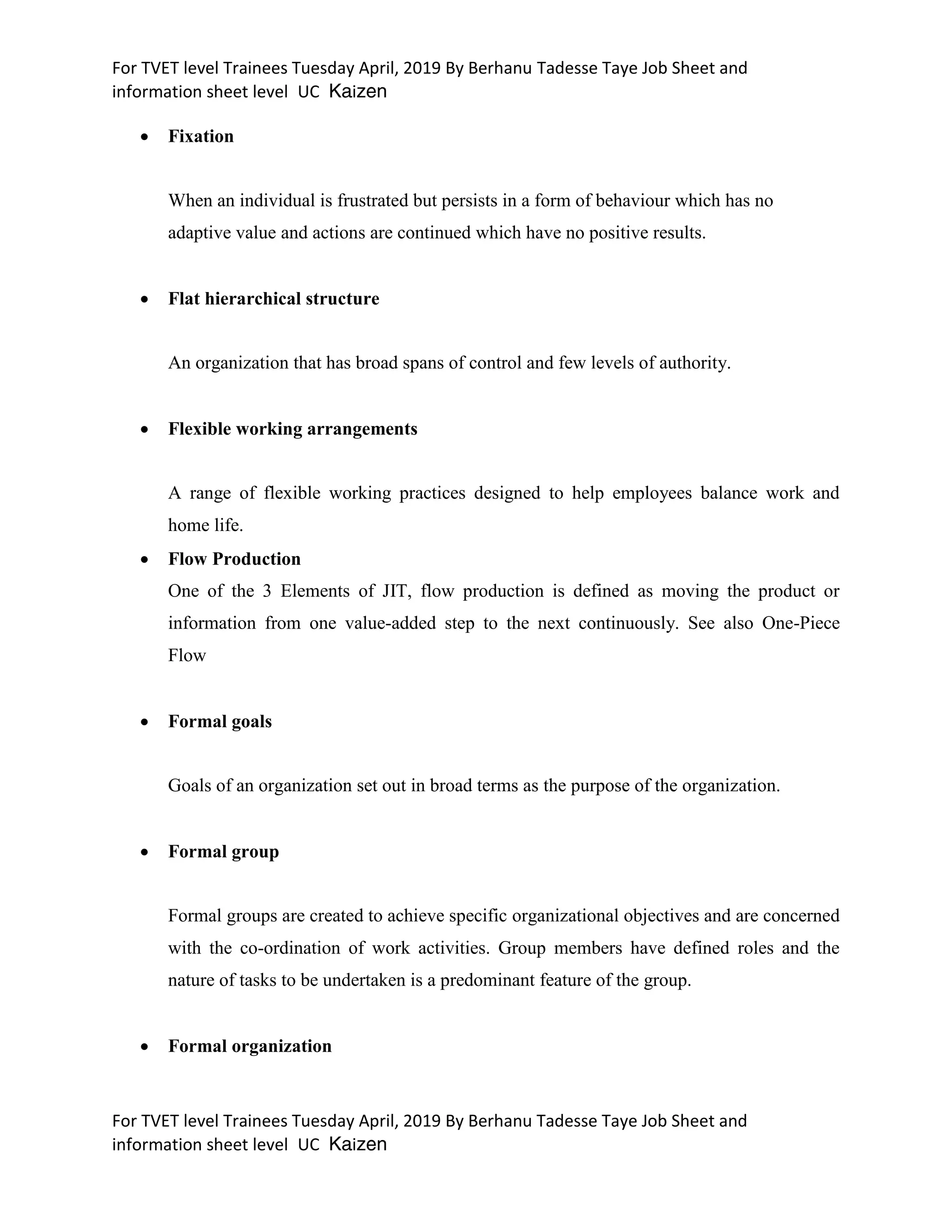

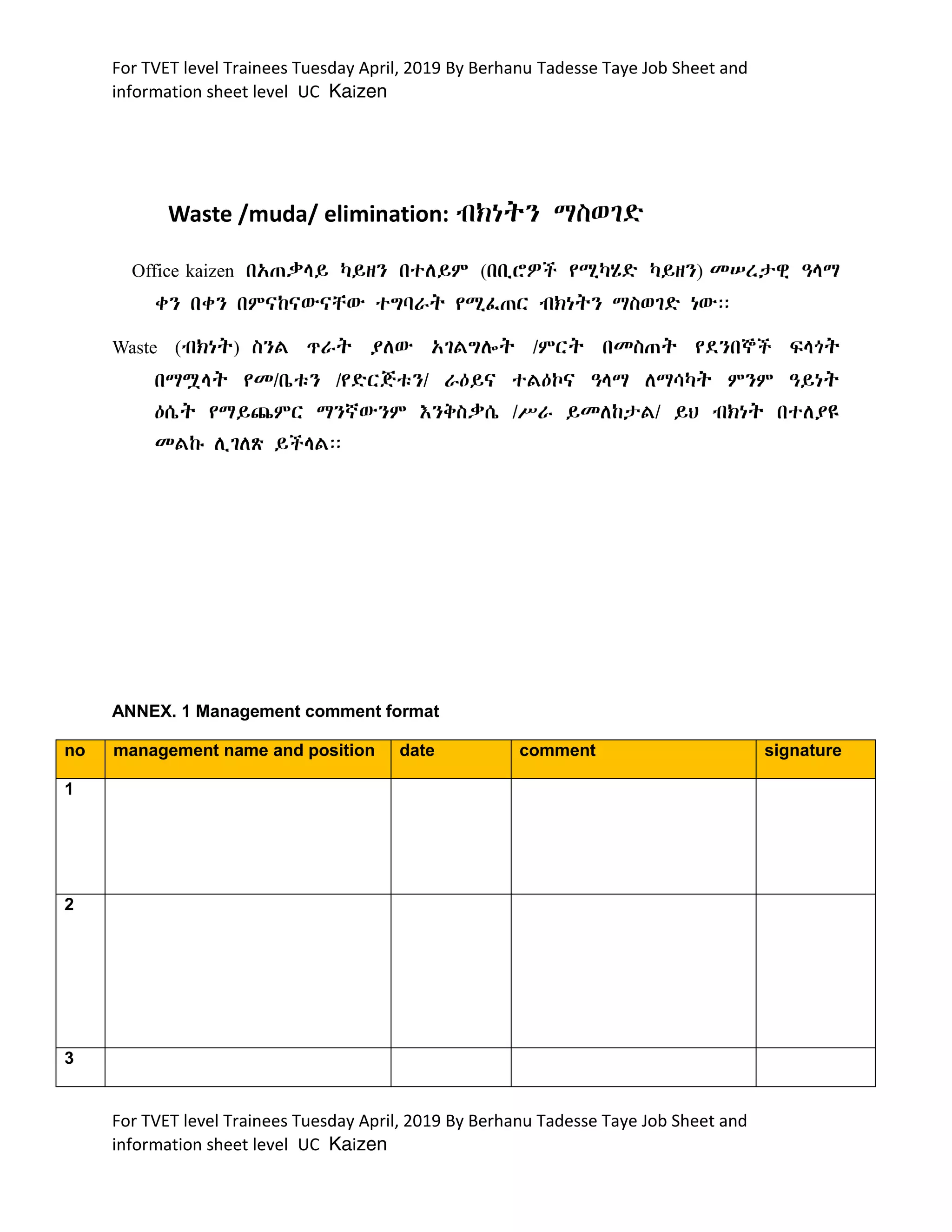

3.1 Meaning and concept

According to Wikipedia, Kaizen, Japanese for "improvement", or "change for the better" refers to

philosophy or practices that focus upon continuous improvement of processes in manufacturing,

engineering, and business management. It has been applied in healthcare, psychotherapy, life-

coaching, government, banking, and other industries. When used in the business sense and applied

to the workplace, kaizen refers to activities that continually improve all functions, and involves all

employees from the chief executive to the assembly line workers. It also applies to processes, such

as purchasing and logistics, which cross organizational boundaries into the supply chain. By

improving standardized activities and processes, kaizen aims to eliminate waste. Kaizen was first

implemented in several Japanese businesses after the Second World War, influenced in part by

American business and quality management teachers who visited the country. It has since spread

throughout the world and is now being implemented in many other venues besides just business and

productivity

Kaizen is a system of continual undertaking by an enterprise to improve its business activities and

processes with the goal to always improve quality of products and services so that the organization

can meet fully customer satisfaction. KAIZEN can be built in and run with an integrated and

company-wide approach through collaboration of all the levels of the organization that are top

management, middle managers and front-line employees. Commitment, genuine participation and

motivation of all the three actors are critical factors. KAIZEN normally places the foremost

importance in improvements at the front-line workplaces as the foundation of all the improvements

efforts.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-91-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

KAIZEN encompasses all the areas that are related to quality, cost, and delivery, whose

simultaneous improvements are essential in achieving customer satisfaction and success of the

organization, KAIZEN, as undertaken by an enterprise, involves continual, dynamic and self-

disciplined practice in the quest of improvements towards ever higher quality and productivity. In

this perspective, the practice of KAIZEN is conducive to creation of a corporate culture in which

the organization’s members are endogenously self-motivated to work together to continually self-

innovative and improve their organization. It also promotes the realization of human potentials of

all the members of the organization.

Kaizen is a philosophy and approach for the continuous incremental improvement of performance.

The main thing you need to know to begin a continuous improvement program is how important it

is- how the smallest ideas can lead to the greatest results. Kaizen involves every employee in

making change—in most cases small, incremental changes. It focuses on identifying problems at

their source, solving them at their source, and changing standards to ensure the problem stays

solved.

These continual small improvements add up to major benefits. They result in improved

productivity, improved quality, better safety, faster delivery, lower costs, and greater customer

satisfaction. On top of these benefits to the company, employees working in Kaizen-based

companies generally find work to be easier and more enjoyable—resulting in higher employee

moral and job satisfaction, and lower turn-over. Kaizen is a system that involves every employee -

from upper management to the cleaning crew. Everyone is encouraged to come up with small

improvement suggestions on a regular basis. This is not a once a month or once a year activity. It is

continuous. Japanese companies, such as Toyota and Canon, a total of 60 to 70 suggestions per

employee per year are written down, shared and implemented.

In most cases these are not ideas for major changes. Kaizen is based on making little changes on a

regular basis: always improving productivity, safety and effectiveness while reducing waste.

Suggestions are not limited to a specific area such as production or marketing. Kaizen is based on

making changes anywhere that improvements can be made. Western philosophy may be

summarized as, “if it isn’t broke, don't fix it.” The Kaizen philosophy is to do it better, make it](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-92-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

better, and improve it even if it isn't broken, because if we don't, we can't compete with those who

do.

Kaizen involves setting standards and then continually improving those standards. To support the

higher standards Kaizen also involves providing the training, materials and supervision that is

needed for employees to achieve the higher standards and maintain their ability to meet those

standards on an on-going basis.

The ten principles for improvement shown below describe the spirit you need to have in order to

be successful in your kaizen activities.

3.1.1 Phase one: - Planning and preparation phase

This phase leads you thorough the steps of preparing for Kaizen event. Upper management will

have given guidelines to the event coordinator. The coordinator and the plant manager, dividing

responsibilities as appropriate, schedule the event, select the area and the problem for improvement,

and choose the team leader (or leaders, if the event will include more than one area.)

3.2 Select an area

The first step is to choose where you will conduct your first Kaizen event. You want to choose an

area that will have an impact but not pose too many difficult problems to solve in the beginning.

Each event will teach you things that will make the next event smoother and easier to run

successfully. Also, each event provides a training ground for new team leaders. As people gain

experience in running events, and as measureable results accumulate in the areas where events have

been run, it will become possible to tackle more complex lines and difficult problems. Start slowly

and build momentum as you gain confidence and experience. You will get each time you do an

event and so will your teams.

You can choose several areas where you would like to start and compare the merits of each. But

during the implementation of the Kaizen event in the selected area the enterprise can disseminate to

other work station, and finally the enterprise will have the all compound Kaizen implemented. This

will ensure that you start with the best one first, based on several criteria, and help you determine](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-93-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

what will be next. Each Kaizen event should be chosen in order to create a progression of results

that support the enterprise the implementation of Kaizen. There are a number of things to consider

during area selection.

3.2.1 Toyota Production System

The idea of integration of production processes in a continuous flow came from Henry Ford in

the beginning of the 20the

Century. His practices were benchmarked by Kiichiro Toyoda, Taiichi

Ohno and others at Toyota, and further developed the concept know as Toyota Production

System (TPS).

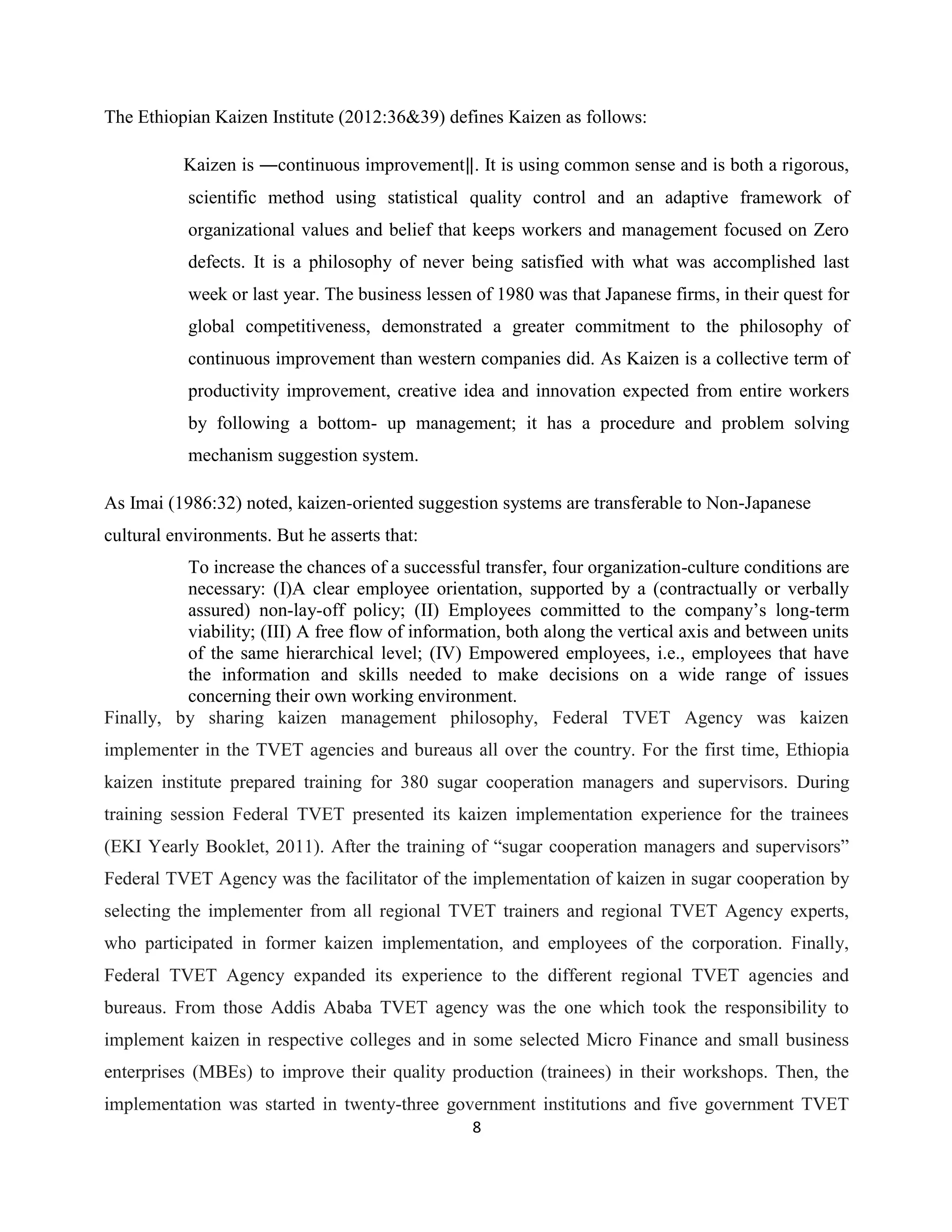

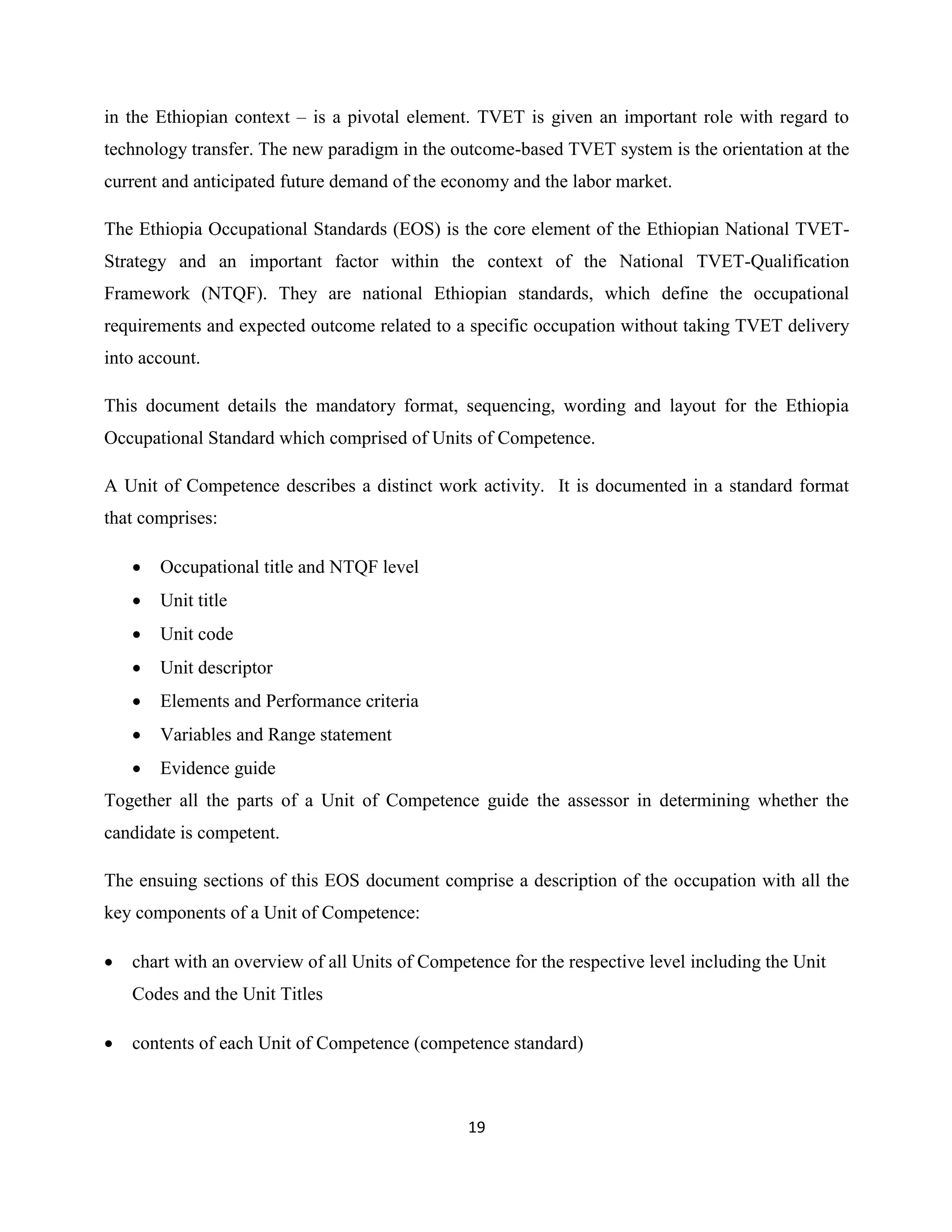

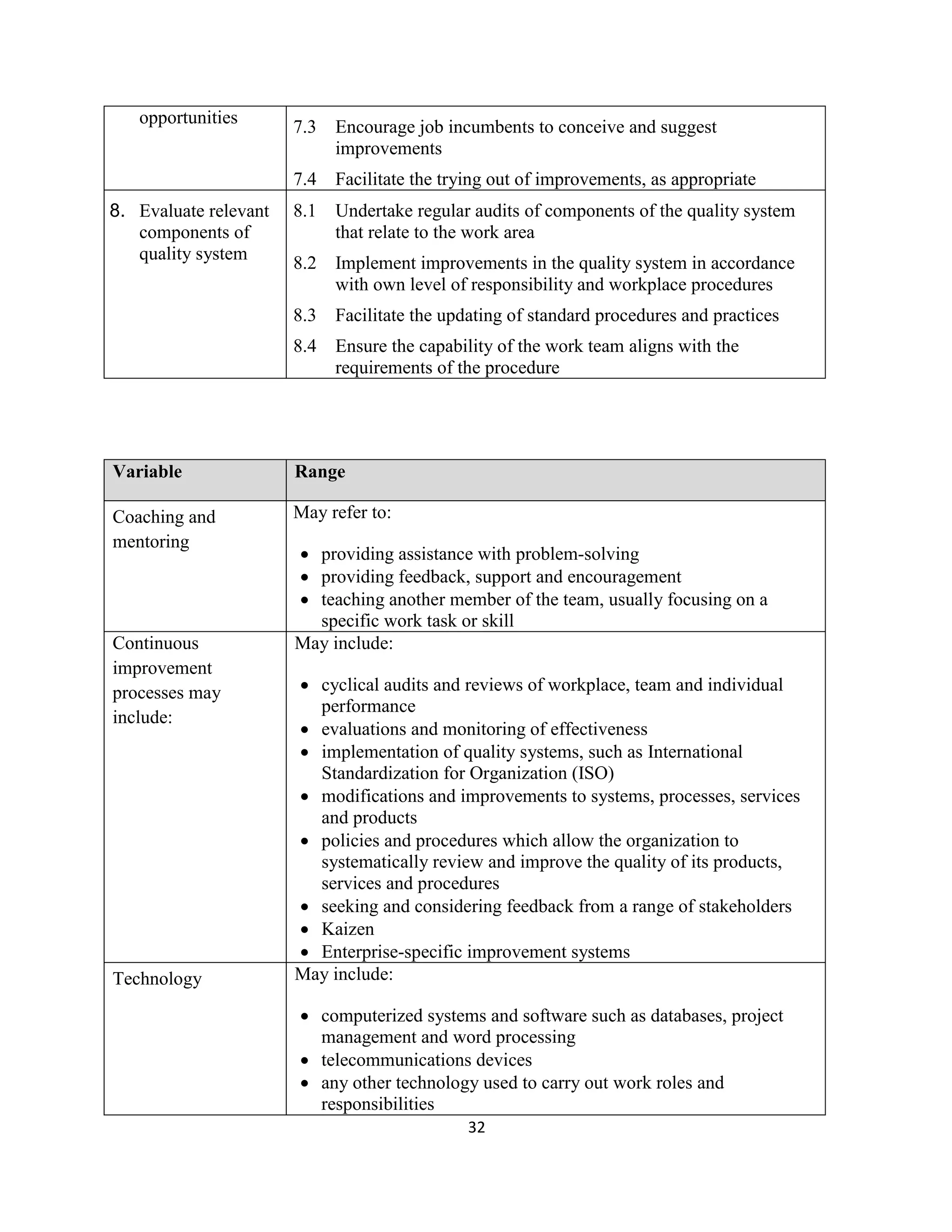

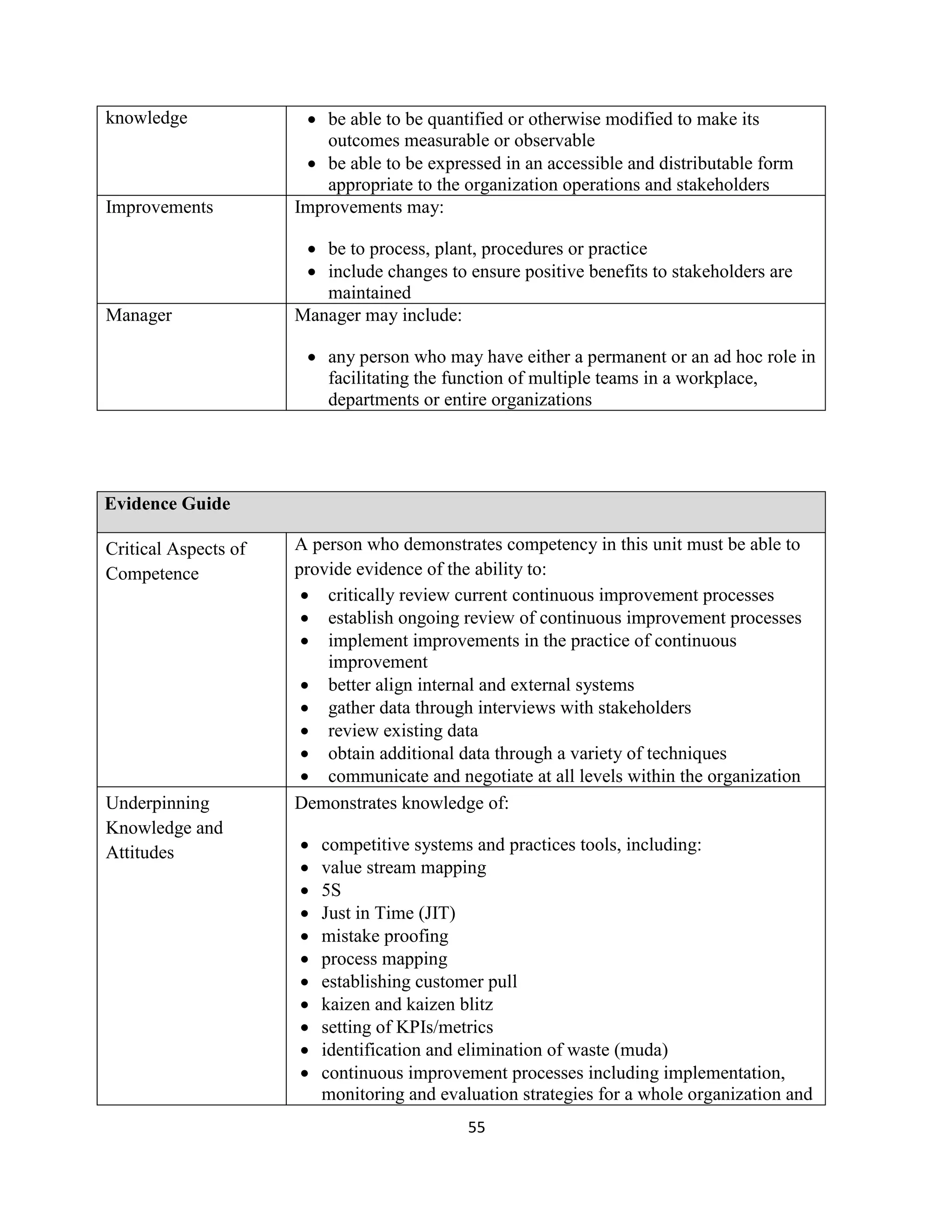

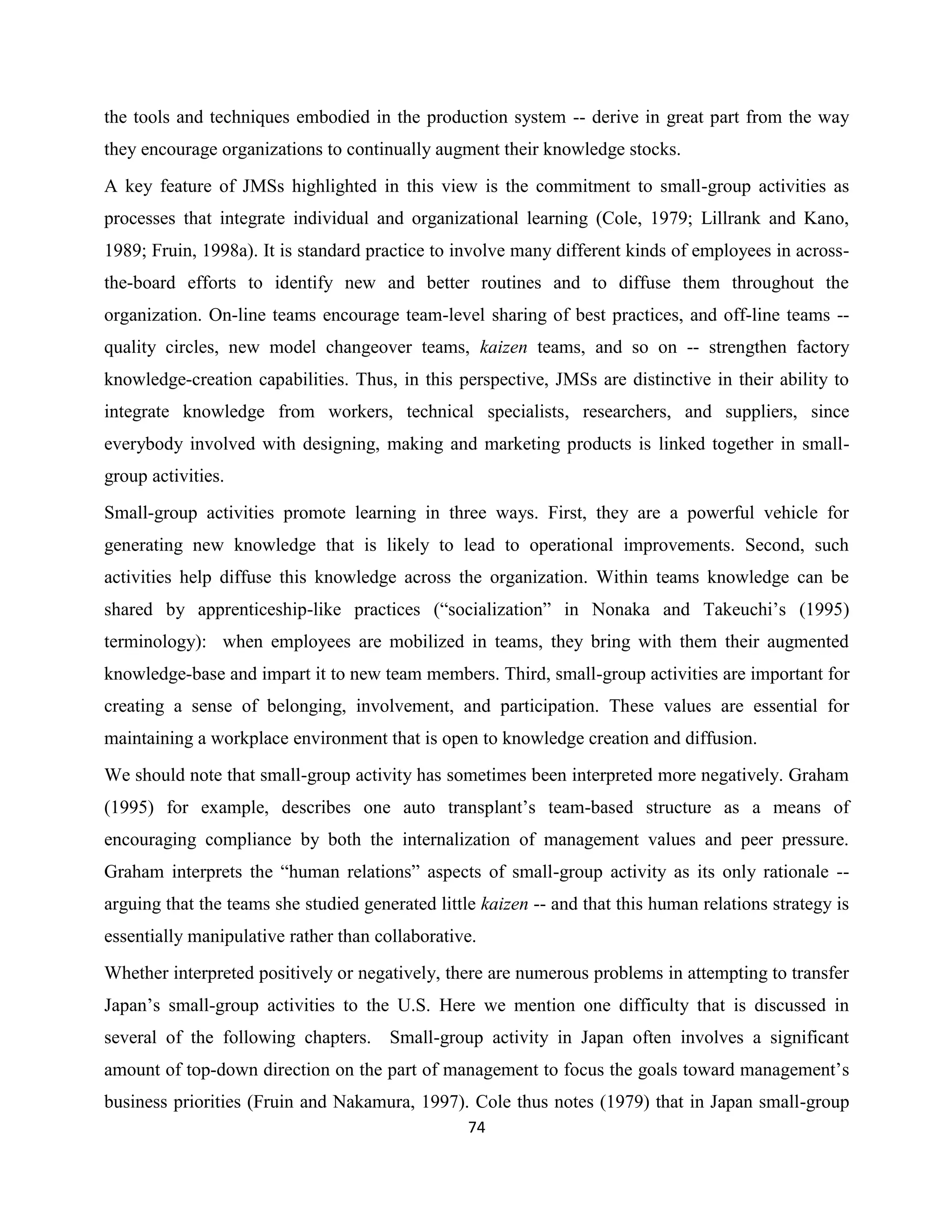

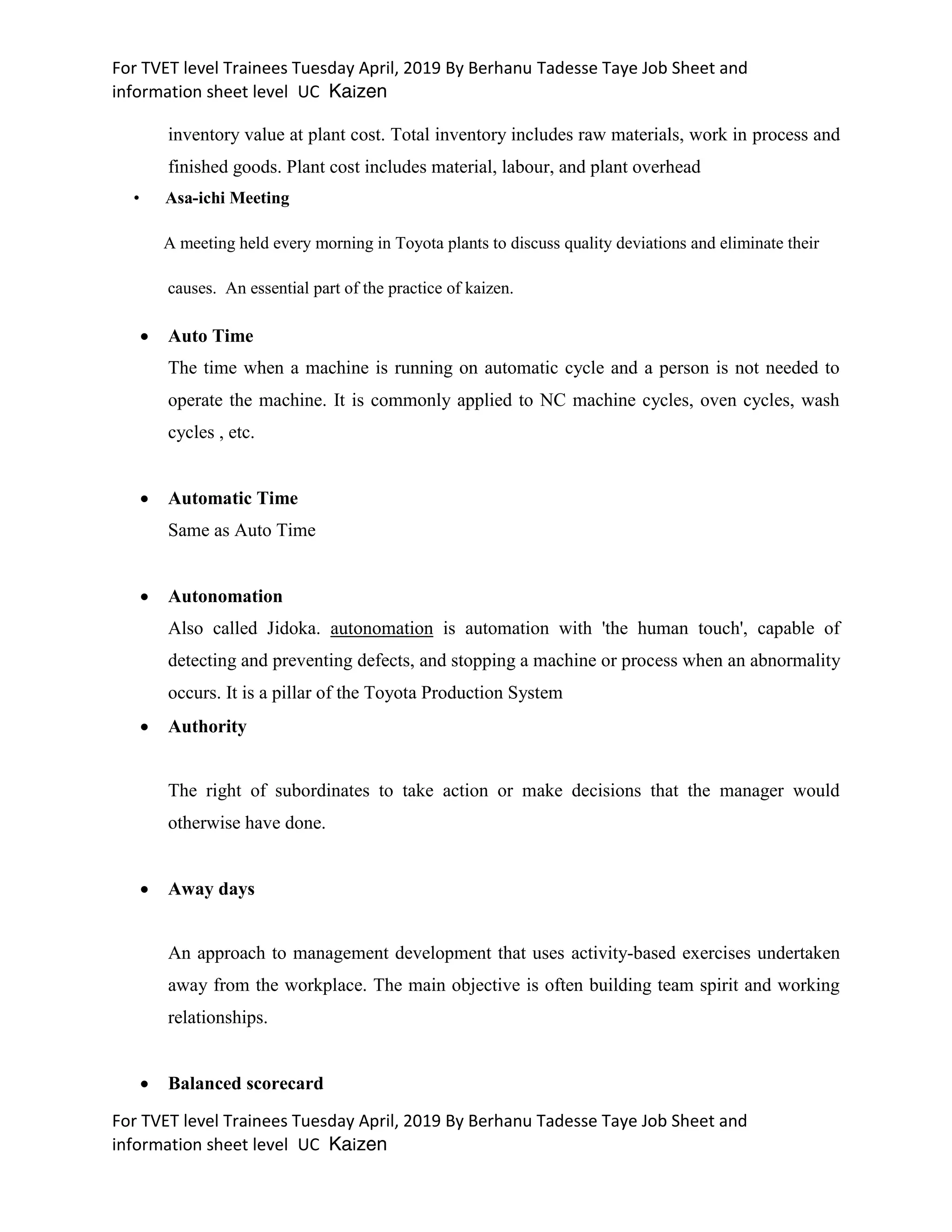

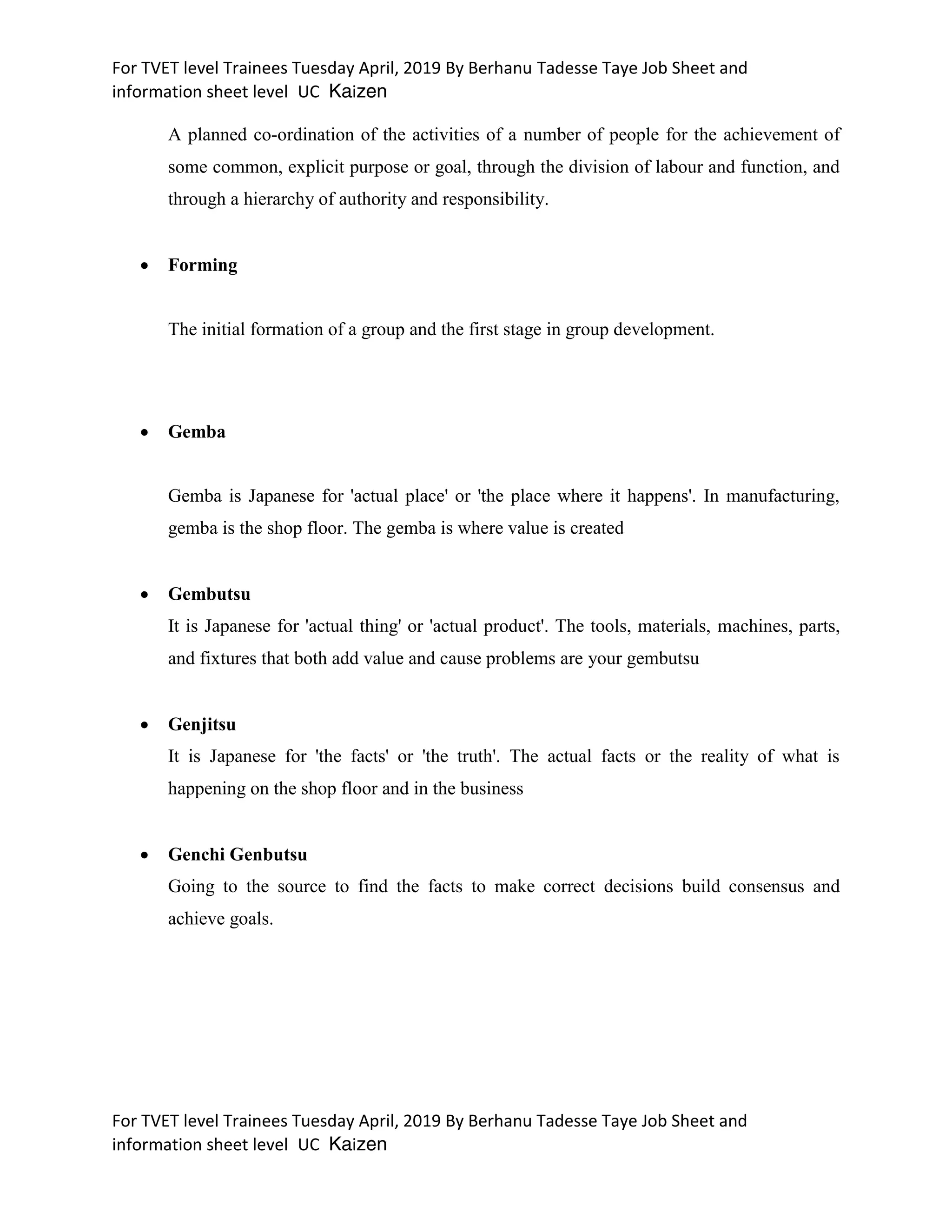

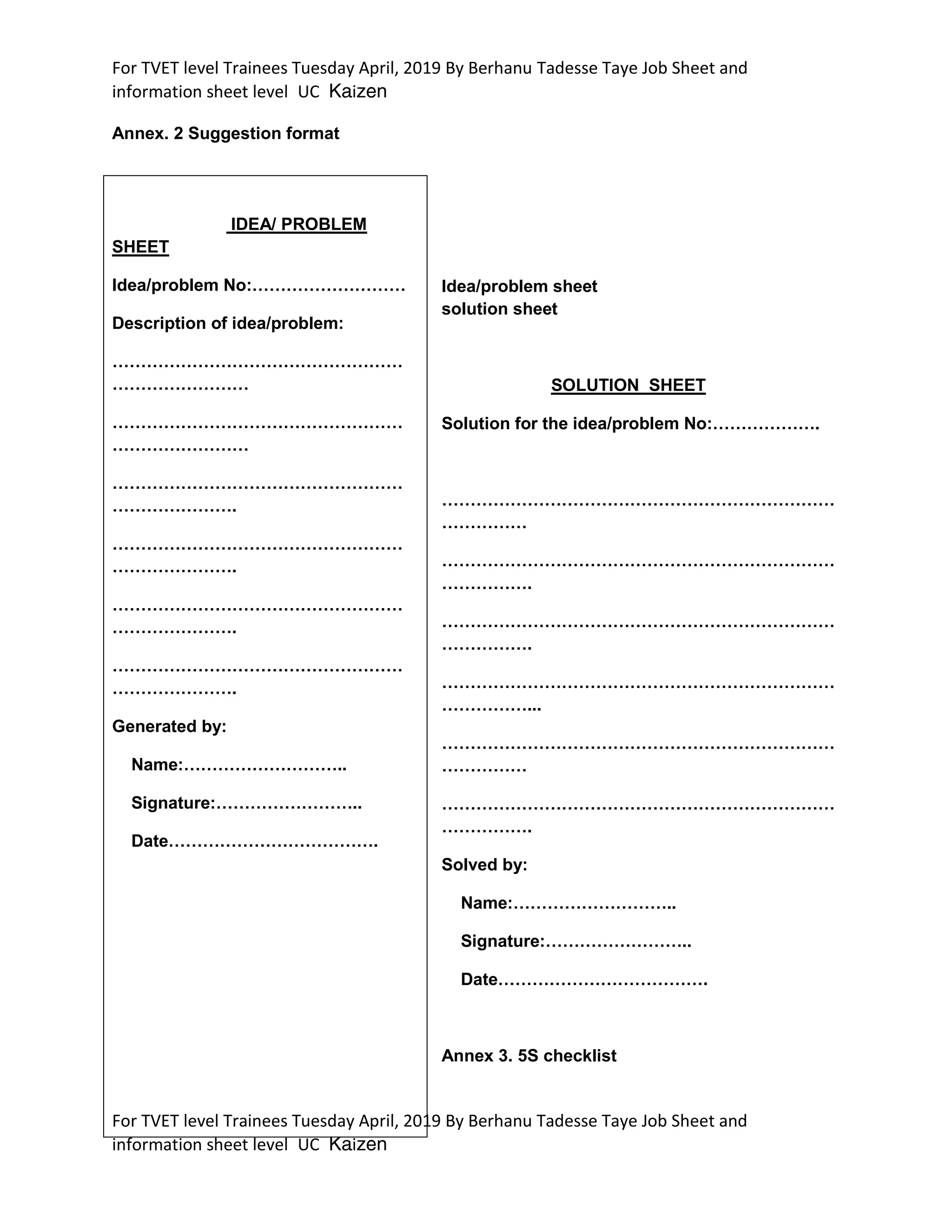

KAIZEN EVENT AREA SELECTION MATRIX

Criteria Area/line A Area/line B Area/Line C

Deluged with WIP

Activities occur all over the plant

Significant bottlenecks

Frequent, major production stoppages

Everything is mess

Product is medium to high volume

Cell of no more than 12 operators

Complete, not a partial process

4-6 processes to complete the part

Visible, robust process

Process can be copied in other areas

Significant market or financial impact

Operational problems(not management issues)

to resolve

Operators have already been cross-trained

Operators have been exposed to kaizen events

Most employees are familiar with the area](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-94-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Table 8 Kaizen Event Area Selection Matrix

Toyota Production System is based on the idea of optimization of production through complete

elimination of waste, which leads to work efficiency and lower costs. Its name and origin come

from the Japanese Toyota Motor Corporation and is also referred to as ‘’Lean Manufacturing

system’’ or ‘’Just-In-Time (JIT) system’’. The term also became known as ‘’Lean Thinking’’ or

‘’Lean Philosophy’’, which is due to the wide-optional nature of applicability of the improvement

concept. Examples of the implementation of the concept come from, but are not restricted to

health care sector, service sector, sales, maintenance, and government.

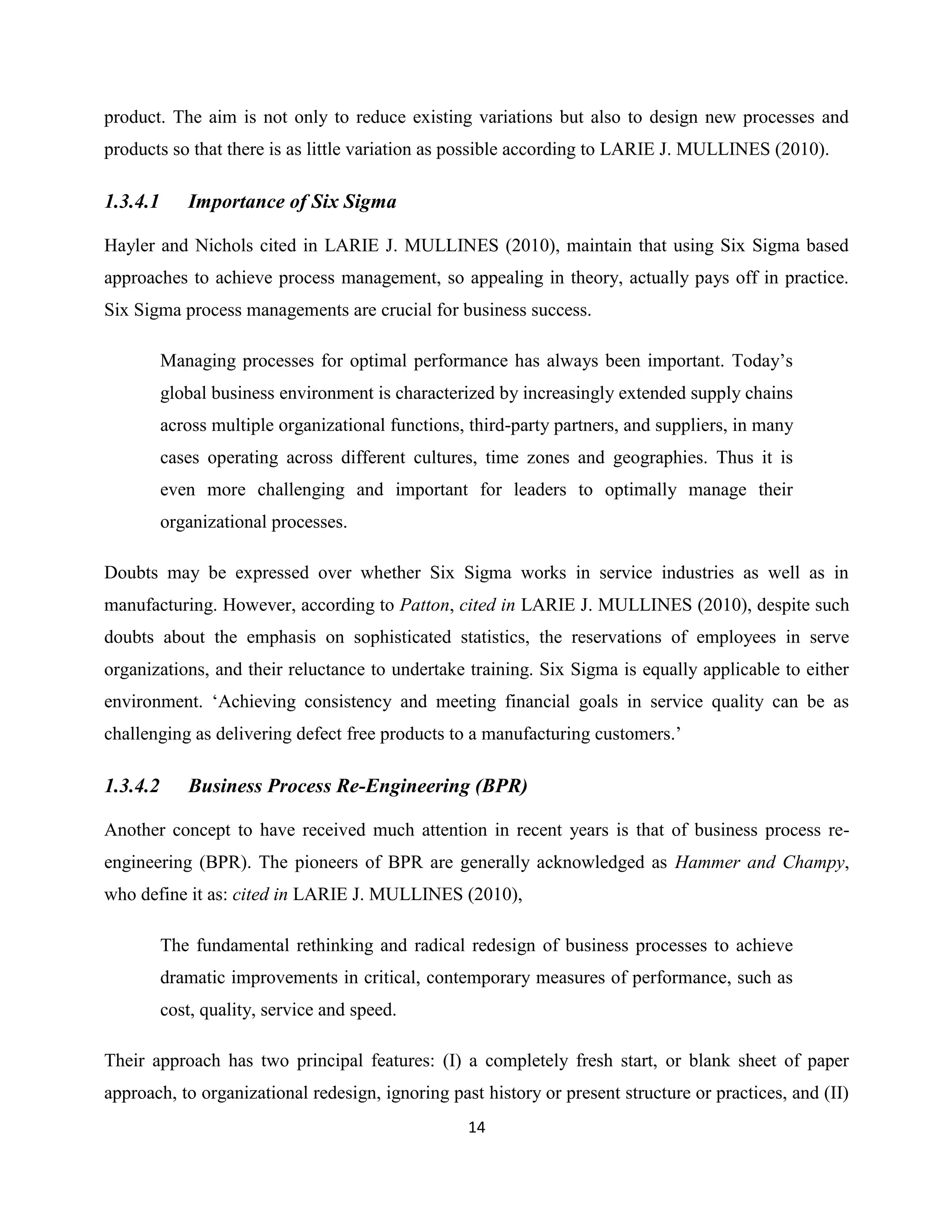

The fundamentals of TPS are visualized in the model developed by Toyota, known as Toyota

Production System House (Figure 2-2).](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-95-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Figure 10 Toyota Production System House

(Source: http://www.gembutsu.com/system_files/library/15.pdf )

TPS is based on two concepts – ‘’Jidoka’’ and ‘’Just –In-Time’’, which are occupied with the

elimination of the defective products and wasteful practices. The first concept is translated as

‘’automation with a human touch’’ and referrers to the visualization of the problems during

production, i.e. the ability of the machine to recognize and stop the production in case defects occur,

which ultimately leads to improved quality in the production. The concept of JIT refers to the

consistency and reliability of production in a continuous flow with elimination of waste e.g. extra](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-96-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

inventory, extra material handling et cetera.

TPS lays ground on stability - through work standardization and the tools of continuous improvement

(Kaizen), and waste reduction - through production leveling (Heijunka). Toyota’s business

philosophy is based on motivation and training of the personnel, therefore central role in Toyota

Production System, Source: http://www2.toyota.co.jp/en/vision/production_system/ (07.03.2010) the success

of the processes, the continuous improvement, and the system sustainability play the commitment and

good training of the personnel. Continuous improvement and stability can be sustained through

techniques such as 5S, Standardization, Visual control and management. Liker (2004) suggests that

Lean has four dimensions and in order to create a Lean organization, all of them have to be applied.

These four dimensions are captured in the Toyota model of successful management style and

uniqueness known as the ‘’4P’’ model (Liker 2004).](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-97-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Figure 11 The Toyota Way - '4P Model' (Liker 2004, p.6)

Liker (2004) asserts further, that despite employing variety of TPS tools, it is possible to follow

only a select few of the Toyota Way principles, which will lead to short-term, non-stable jumps

on performance measure, while truly practice of the full set of Toyota Way principles will be in

accordance with TPS and will lead to sustainable competitive advantage.

TPS has become well known and studied worldwide. Toyota 4P model has been applied

successfully in different types of organizations for the improvement not only of production

but also of various business processes, and despite the fact that is a relatively new

philosophy it has already been proven as efficient. The Toyota model and TPS have laid the

foundation of a completely new paradigm - Lean Thinking and Lean Production.

3.2.2 Select the team members

The team leader’s first responsibility is to select the team members. The team members are the people

who actually conduct the kaizen event. There should be a maximum of 15 people on the team. Team

members must be created depend on the task that each member is doing and also chosen for their ability

to work together and also because they understand and support the potential of the kaizen event. Those

who complain or belittle the potential will slow down or even block success, especially for the first few

events you implement.

3.2.3 Select the team leaders

After choosing the area and the problem focus for the team leader must be identified. The team leader

lead conducting event; he or she chooses the team members prepare for the event, creates the schedules,

gathers the materials and tools, and follows all event activities, reobstacles and helping with

documentation and report leader keeps the team on target, ensuring that they make objectives of the

event. Team leaders should be selected enough ahead of the event so that they can rearrange their

schedules to make leading the event their top priority.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-98-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

3.2.4 Prepare the Team Leader

Team leaders will need to know the goals and objectives of the event, the production requirements, and

the expectations of team members. Information from past events should be shared with the team leader,

such as past problems encountered and gains achieved. The team leader should also be given information

about what to do in an emergency, safety rules related to the area, what to do when things bog down,

how to handle personality conflicts, and where to access needed data. In addition to sustain the team

members, the leader has a number of response and activities before, during, and after the event.

In order to have a big impact right away choose an area:

That is deluged with WIP

That has activities that occur all over the plant

That has a significant bottleneck or other major hindrance production flow

Where everything is a mess

3.2.5 Train the team

Potential team members with a positive outlook may in the fundamentals of Kaizen. All team members

and the team leader need to be trained in the methods that will be used or implemented during the event.

Team leader is responsible for scheduling and coordinating required training in advance of the event and

for provision for the team members to discuss and absorb what they learned. Training will be conducted

mainly by the human resources but it can also conducted by the training coordinator and team leader

also.

3.2.6 Select a problem for improvement

Once the area has been selected, the focus for the kaizen event must be decided. Be sure that you mark

the boundaries of the chosen area clearly and that you set and maintain the boundaries during the kaizen

event. Talk to the people who work in the selected area about the project and work with them in deciding

on the problem to be improved.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-99-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

The reasons you chose this particular area for a Kaizen event probably included some understanding of

what is needed in this area. Now it is time to check your assumptions and examine the conditions and the

process used in this area more closely. In selecting a focus for the Kaizen event several things need to be

considered. Has 5S been conducted there? Should that be the focus of the first event in this area or do

you want to implement 5S more gradually before conducting the event?

Seven types of waste

The main seven types of waste are-

1. Overproduction

2. Excess Inventory

3. Waiting

4. Transporting

5. Defect-making

6. Unnecessary Motion

7. Excess Processing

3.2.6.1 Overproduction

Cause

Workforce and facilities in excess of production needs

Big lot production

Anticipatory production

Machines that turn out parts too quickly

Big and fast production machine](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-100-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Products are produced on and on

3.2.6.2 Outcome

Disturbance of flow

Increase in inventory(products, stock in- progress)

Outbreak of defects

Deterioration of turn-over ratio of funds

Advance preparation of materials and parts

Disturbance of flexibility in planning

3.2.6.3 How to Eliminate Overproduction

Full work

Line balancing

One-piece flow

Pull production

Quick-change over productions

Level production

3.2.6.4 Excess Inventory

Cause

Weak inventory control awareness

Bad facility layout

Big lot production](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-101-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Bottle-neck process

Anticipation production

Speculative production

Outcome

Lengthened delivery time

Nipping an improvement in the bud

Waste of space

Needs for inspection for transportation

Expansion of working capital needs

How to eliminate excess inventory

U-shaped manufacturing cells, layout of equipment by process instead of operation

Production leveling

Regulatory the flow of production

Pull production using Kaizen

Quick changeover productions

3.2.6.5 Waiting

Idle time caused by both human and machine waiting. The need to wait may be caused by many things,

including conveyance delays, machine failures, or some operators working too fast or too slow. It is

important to examine the causes of idle time.

Cause](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-102-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Bottle-neck process

Bad facility layout

Obstruction of flow

Trouble at previous process

Capacity imbalance

Big lot production

Outcome

Waste of manpower, time, and machines.

Increase in the In-process Inventory

How to eliminate waiting (idle time)

production leveling

product-specific layout

Mistake-proofing

Human automation

Quick changeover

Automation maintenance

Line balancing

1. Transporting

Cause](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-103-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Bad facility layout

Big lot production

Single-skilled worker (over-specialization)

Sedentary operation

Low morale

Outcome

Waste of space

Production deterioration

Increase I transportation processing

Expansion of transportation

Occurrence of scratches and dents

How to eliminate transporting waste

U-shaped manufacturing cells, layout of equipment by process instead of operation

3.2.6.6 Defect-Making

Defect waste includes the defects themselves, the costs of inspecting for defects, responding to customer

complaints, and making repairs all of which increase because of the defects themselves. Human errors

create defects, as does variance in upper/lower tolerances in machine operations. When defects occur,

customer complaints increase. This is one measure of defect rate. Stockpiles of defective products are

another measure of this type of waste. When defects occur at a significant rate, inspection staff is often](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-104-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

increased so that the defects are not passed on to the customer and inventory may be increased to make

up for the defective part produced. In addition, productivity decreases and the cost of materials rise.

Cause

Emphasizing down-stream processes by inspection

Poor methods and standards for inspection

Excessive quality requirements

Material handling and conveyance

Lack of standard operation

Outcome

Increase in material cost

Productivity deterioration

Increase in personnel and processes for inspection

Increase in defects and claims

How to eliminate Defects

Standard operations

Mistake-proofing devices

Full-lot inspection

Building quality in at each process

Flow production

Elimination of the need to pick up and set down work pieces](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-105-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Improvement of jigs using human automation

Promotion of value analysis and value engineering.

3.2.6.7 Unnecessary Motion

More inventories naturally leads to more motion. Motion refers to any transport or transference of

materials, parts, finished goods, from one place to another for any case. Material handling is one part of

motion.

Causes

Isolated operation

Craftsmanship traits prevail

Bad layout

Large lot production

No education or training

Outcome

Increase in manpower and processing

Minimization of skills

Unstable operation

Unnecessary movement

How to eliminate unnecessary motion

U-shaped manufacturing cells](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-106-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Flow production

Multi-skilled operations

Standing to perform operations

Higher utilization rate

3.2.6.8 Excess Processing

Processing waste refers to operations and processes that may not be necessary. An increase in defects

may result from inappropriate or outdated operations or processes. Increased worker hours may result in

process waste and defects. Lack of training or standardization may also produce process waste. Design

changes may eliminate the need for certain operations, yet workers may continue to do those operations

because they don’t yet understand the change. For instance, screw holes may continue to be drilled even

though the fastening method has changed to welding or glue, or too many screws may be used.

Outcome

Unnecessary processing and operation

Incomplete standardization

Materials are not studied

Increasing in manpower and processing

Lower work efficiency

Increase in defects

Cause

Lack of analysis of proper order of processing

Inadequate study of processes](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-107-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Inadequate study of operations

Lack of analysis of contents of operation

Improper jig and its use

Insufficient standardization

Lack of analysis of materials

How to eliminate excess processing

U-shaped manufacturing cells

Flow production

Multi-skilled operations

Standing to perform operations

Higher utilization rate

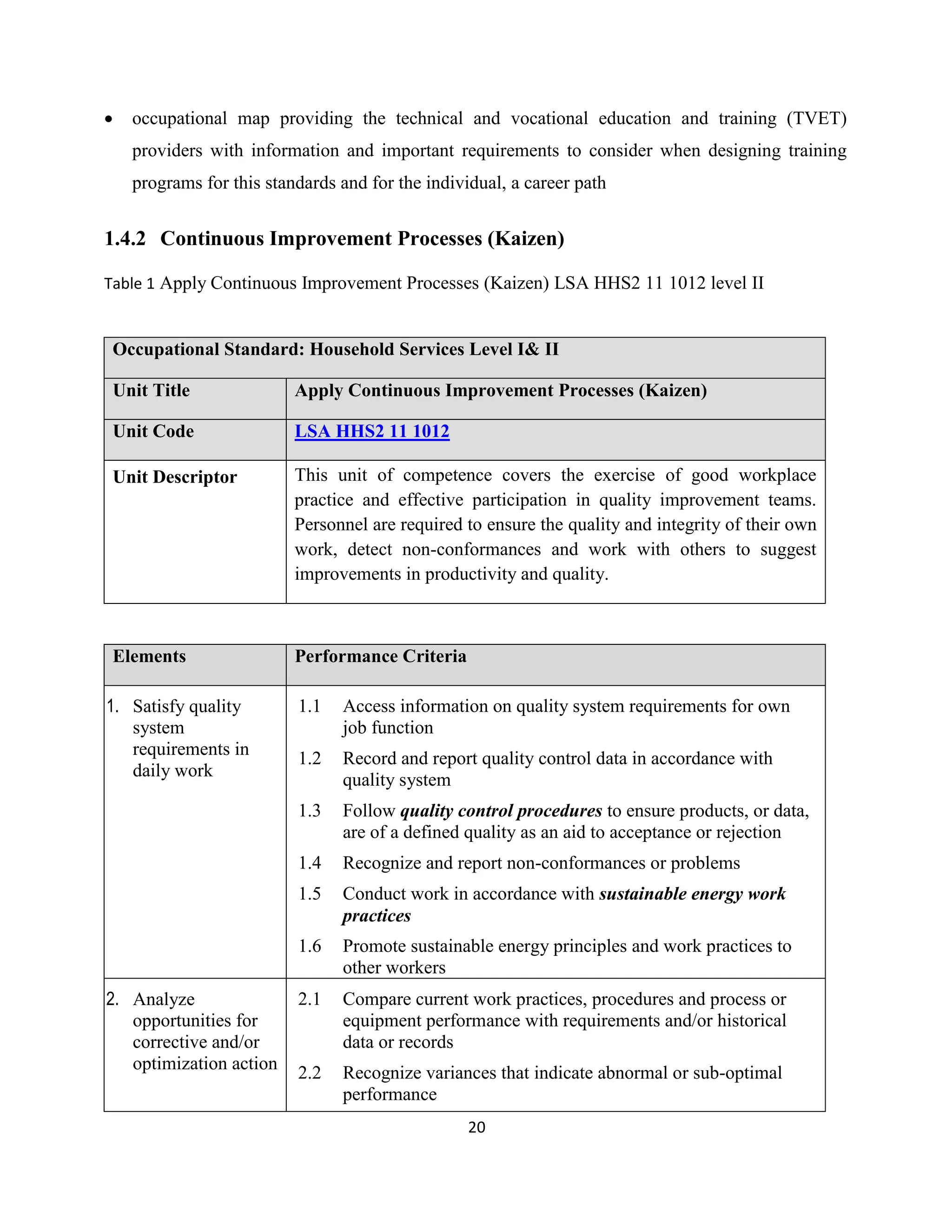

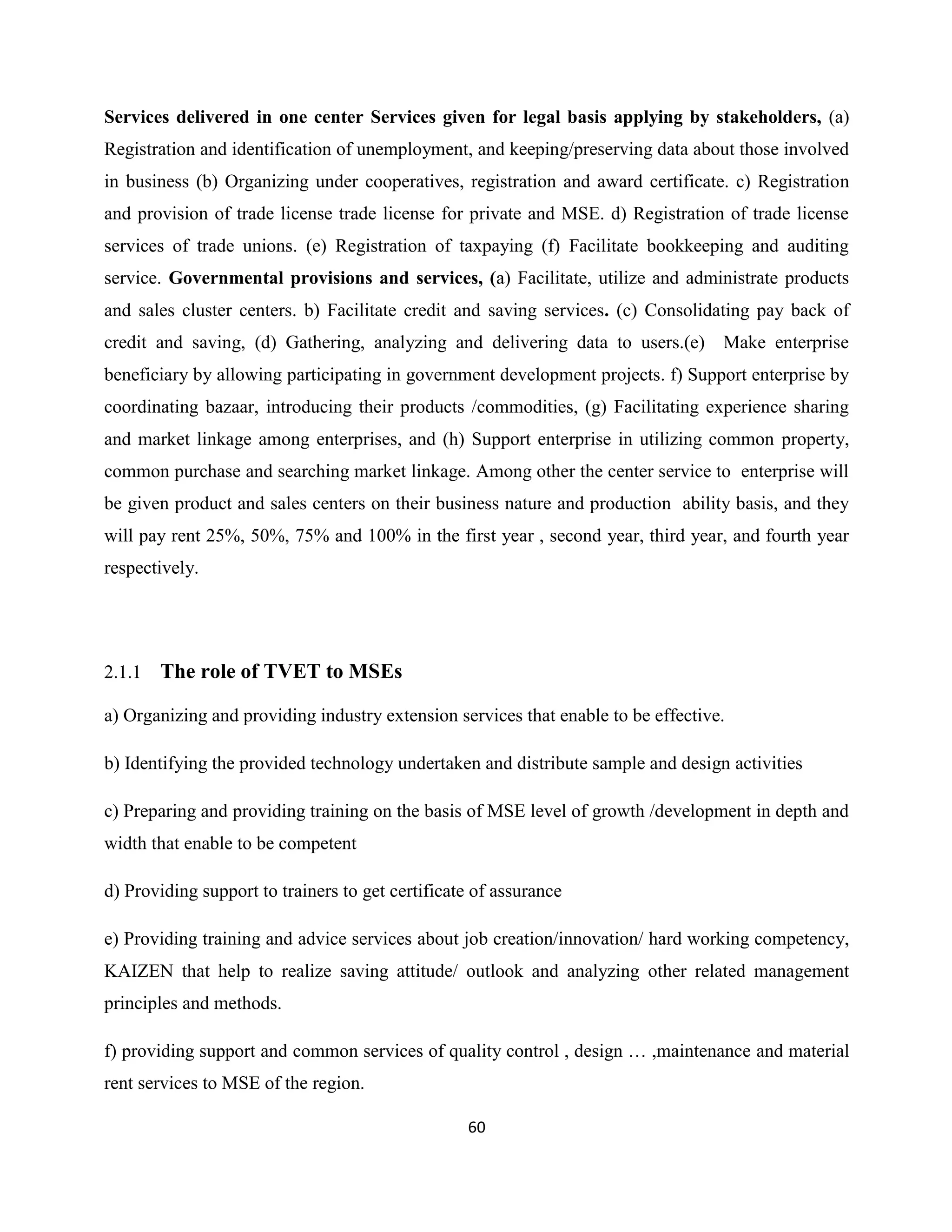

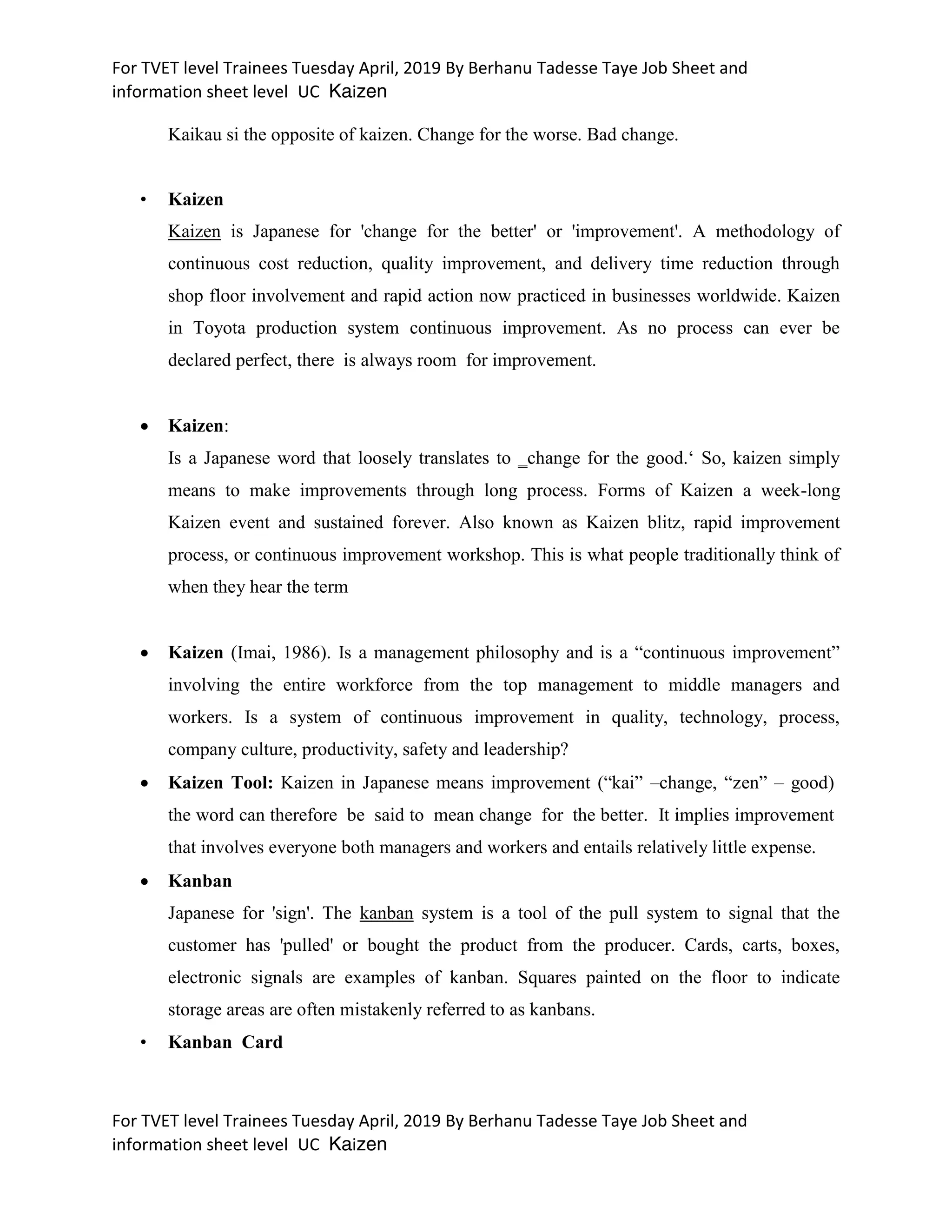

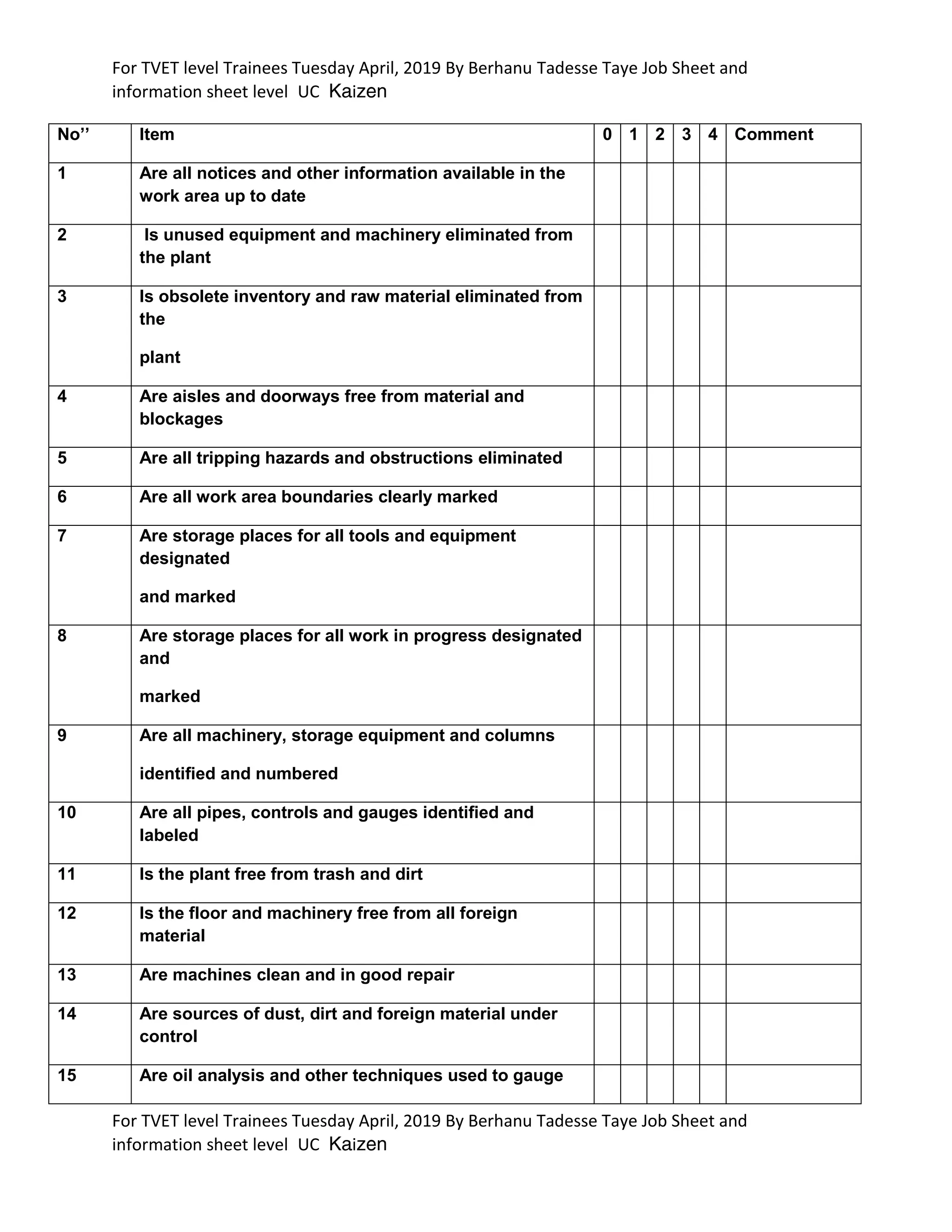

3.3 Kaizen board

KAIZEN continuous improvement board](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-108-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

STAFF PERFORMANCE

RECORD

IMPOROVEMENT/SUCCESS

CORNER

Picture of well performing

employee...

PROBLEM/IDEA CORNER

One weeK>>>

SOLUTION CORNER

One week>>>

Table 9Kaizen board KAIZEN continuous improvement board

N.B. The size of the stand should be 2 times a flipchart paper.

Additional to the stand we need space for:

Green;blue;red sticker

Marker

Idea and solutions formats

Tape

How to use the “KAIZEN continuous improvement board”?

0%

100%

C…

C…

S

e

r

i…

Idea

A

Problem

2

Idea

B

Idea

C

Problem

1

Solution

A

Solution

B](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-109-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

This board is the main source of information regarding KAIZEN and the actual status of improvement

and activities leading to further improvements. For every working group or team such a board has to be

developed and kept up to date. Therefore an enterprise can be divided in many small units which should

be encouraged to work “as independent as possible”. A team has to focus on how they can contribute to

the company’s overall set of targets. As long as the team is able to transform their ideas and small

problems into solution, they should do this immediately without asking for help from outside the team.

This is real KAIZEN!!! Only if a problem is too big, too much money needed or other departments or

experts needed for realizing a solution, the team has to transfer the idea/problem (a reason how a solution

contributes to improvement should be part) to the next higher hierarchy level.

As soon as every small unit or team is with such a KAIZEN board, it’s easy for the whole management

to be informed at any time, just be walking around and check the information given on the KAIZEN

boards. This is the 5th

s – sustain!!! Make sure that the reached improvement level will stay in future.

The information on the board is divided into four corners:

The “Staff performance record corner” shows the actual staff performance as well as the gaps and

need of training on the actual task of the process flow

The “Improvement/success corner” shows the actual status of the three to five most important

improvement targets for this team. Additional you can put samples of success (picture of best

performer from this team, letter of thanks from the GM and the comment from GM (see the

format in the annex)

The “Idea/problem corner” is the place where every team member is expected to place his ideas

or small problems(see the format in the annex)

The “Solution corner” covers the solution actually developing by the team(see the format in the

annex)

Roles for using the board:](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-110-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

1. The staff performance is visible by three different colours red = newcomer; blue = average

performer with space of improvement; green = best performer able to do his process step

independent without outside help)

2. The improvement graphs have to be updated on a weekly basis. As soon as the result is below the

target, the team has to search for a reason why and find an idea or solution for improvement

3. Everybody from the team is invited to put his ideas on the board! After maximum one week time,

the idea/problem should be transferred into a solution! So the Idea paper has to go to the solution

corner!

4. After another week, small solutions have to be put into reality! Bigger solutions/problems have to

be sent to the next hierarchy level for realisation.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-111-2048.jpg)

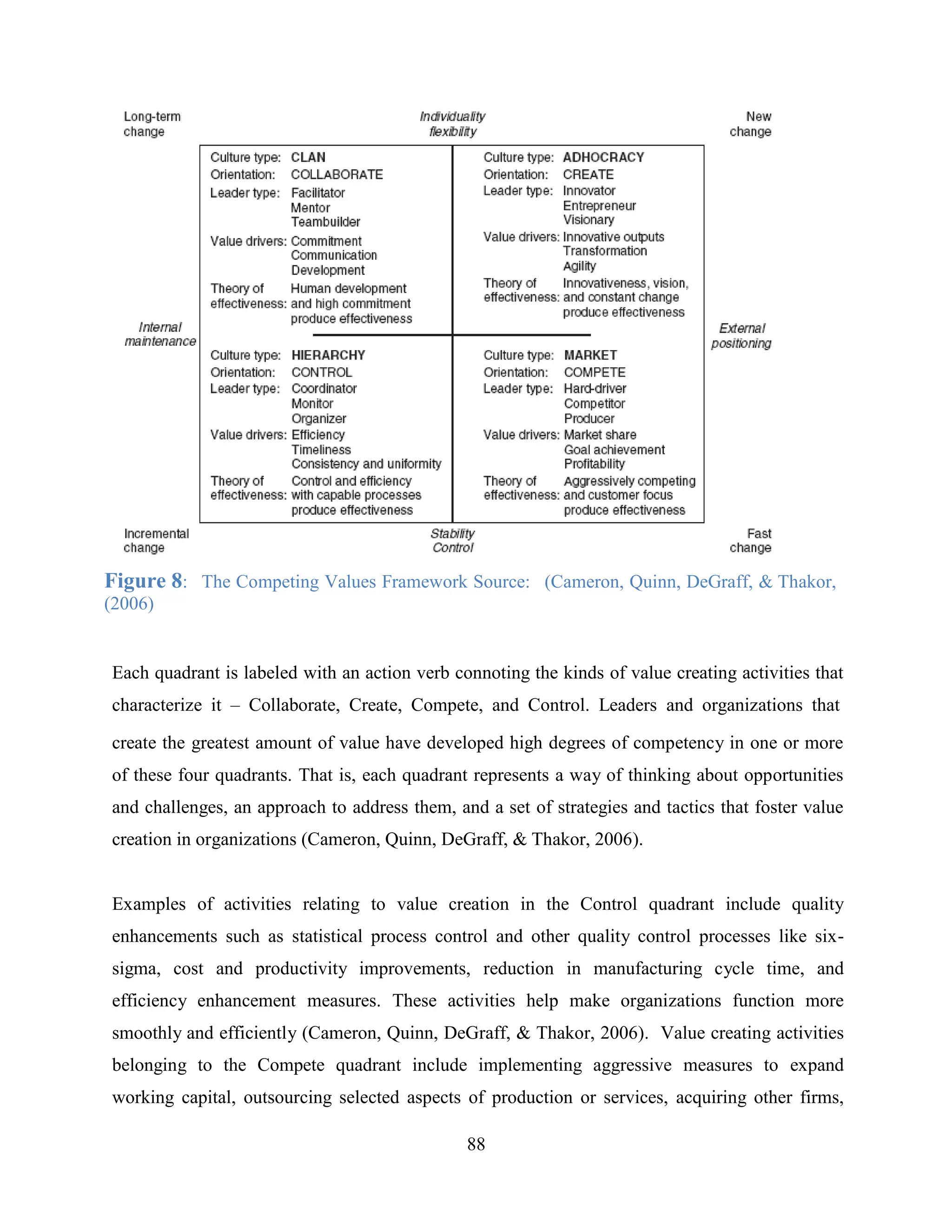

![[ T y p e t h e c o m p a n y a d d r e s s ]

3.3.1 SPMT (Sample Staff Performance Maintenance Tool)

Enterprise logo

Record of staff performance

Maintenance Department Electrical

Employee is able to do the job independent

Employee is able to do the job under supervision

Employee not trained on this job

/ Employee not involved in this job

Name of workers

Name of occupation /job

Managi

ng

depart

ment

Machi

ne

operat

ion

Elec

trica

l/ele

ctro

nic

mai

nten

anc

e

Buildi

ng

electr

icity

win

din

g

M

ac

hin

e

ins

tall

ati

on

Elect

rical

supe

rvisio

n

Mech

anic

supe

rvisio

n

Utility

supe

rvisio

n

Tsegazeab Mehari green / / / / / green green green

Rezene Alemayehu Red Blue Red Blue / / green / Red

Weldeyas Abraha / Blue Blue Blue Blue Red / / /

Gezahegn Libanos / Blue Blue green Blue Red / / /

No of trained staff 1 0 0 1 0 0 2 1 1

No of need staff 2 3 3 3 2 2 2 1 2

Date when trained staff is

needed

Jan oct oct dec feb oct jan jan oct

Gap 1 3 3 2 2 2 0 0 1

Table 10SPMT (Sample Staff Performance Maintenance Tool)](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-112-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

3.3.2 The Deming improvement cycle

Table 11the Deming improvement cycle

Plan – Kaizen Lead works with management to gather information and objectives for improvement.

This includes process area of focus, resources, management and customer complaints about the

process, and any current process performance data that is available.

Do – Kaizen Lead facilitates “Kaizen Event” with assigned resources to analyze current process and

implement improvements to meet management objectives.

Check – Kaizen Lead and team members gather data on the effects of the changes and present results to

management and organization.

Plan

Do

Act

Check](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-113-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Act – Kaizen Lead and team members document and standardize new process and develop a

monitoring plan to ensure improvement gains are sustained.

3.3.3 Ten basic principles for improvement

1. Throw out all of your fixed ideas about how to do things.

2. Think of how the new method will work-not how it won’t

3. Don’t accept excuses. Totally deny the status quo.

4. Don’t seek perfection. A 50-percent implementation rate is first as long as it’s done on the spot.

5. Correct mistakes the moment they are found.

6. Don’t spend a lot of money on improvements.

7. Problems give you a chance to use your brain.

8. Ask ‘why? ‘at least five times until you find the ultimate cause.

9. Ten people’s ideas are better than one person’s.

3.3.4 ‘Improvement knows no limits Kaizen approach the steps that we have to follow

during Kaizen approach are:

1. Project selection - Projects should be selected that are important and have the right scope to

ensure success

2. Owner involvement – owners are involved in the decision making and implementation

3. Data driven – out comes are driven by facts and data, not opinions and assumptions

4. Quick wins – implement quick wins immediately to show success and generate momentum

5. Simple calculations – always provide feedback and praise to team members](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-114-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

6. Celebrate success – always provide feedback and praise to team members

3.3.4.1 Importance of kaizen

1. Kaizen eliminates the hidden costs that result from the seven types of waste that can exist in the

production process.

2. Kaizen improves the value-added operations in the production process so that the product

delivered to the customer is of the high quality, lowest cost, and shortest delivery time possible.

3. A kaizen event allows major changes to be made in practical area quickly and ‘with minimum

loss of production time.

4. ‘Kaizen Improves space utilization, product quality, use of capital, communications, production

capacity and employee retention.

5. Kaizen provides immediate results. Instead of focusing on large, capital intensive improvements,

Kaizen focuses on creative investments that continually solve large numbers of small problems.

Large, capital projects and major changes will still be needed, and Kaizen will also improve the

capital projects process, but the real power of Kaizen is in the on-going process of continually

making small improvements that improve processes and reduce waste.

6. Kaizen Reduces Waste in areas such as inventory, waiting times, transportation, worker motion,

employee skills, over production, excess quality and in processes.

7. Employees working in Kaizen-based companies generally find work to be easier and more

enjoyable-resulting in higher employee moral and job satisfaction, and lower turn-over

8. Kaizen provides immediate results; creative investments that continually solve large numbers of

small problems.

9. The real power of Kaizen is in the on-going process of continually making small improvements

that improve processes.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-115-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

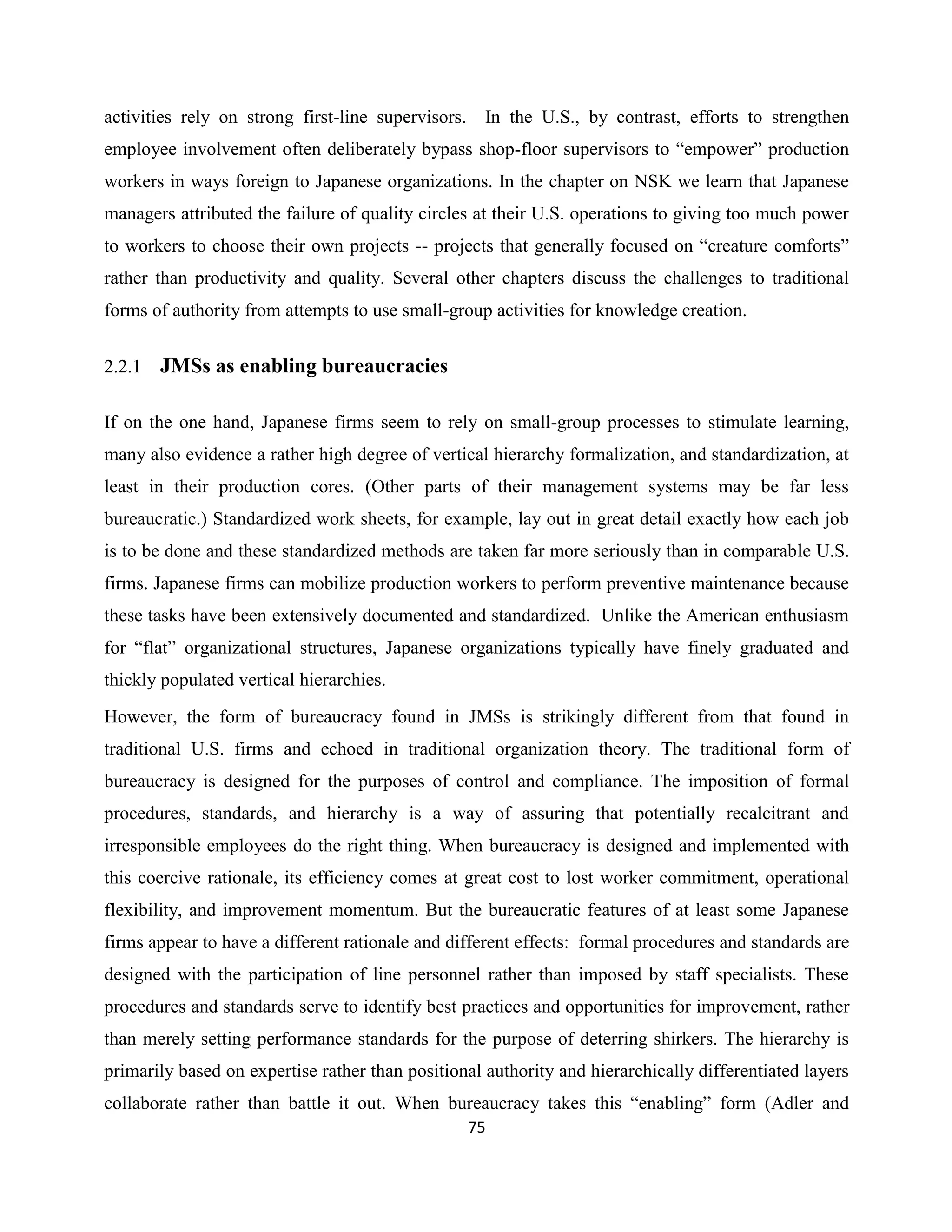

Table 12Kaizen events

There are a number of important things to consider in determining the people who will be involved in

making Kaizen events a success. Of course, the team and the team leader are the principal participants,

but there are many others whose roles will provide the necessaries backup and follow-through that the

team will need before, during and after the event so that their efforts take hold and bring measurable and

lasting result. Everyone involved will need a general commitment to Kaizen event to make it return

optimal improvements to the plant.

KAIZEN

EVENTS

MANAGEMENT

KAIZEN LEAD

(TEAM LEADER)

COORDINATOR

EVENT TEAM

MEMBERS](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-116-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Roles and responsibilities-Management

Management is comprised of executive, process owners, managers of the process being improved.

3.3.4.2 Main responsibilities are

The plant manager’s primary role is to communicate wholehearted support for the kaizen teams

Driven Kaizen or continuous improvement culture

Work with Kaizen lead to identify the process area to be improved and objectives of Kaizen

activities

Attend all kick-off Kaizen events and participates in Kaizen Events as needed for

approval/feedback by the team

Identify resources and provide time and materials to execute activities

Publicly endorse Kaizen improvements activities

Remove barriers to Kaizen team success and empower the kaizen team

Recognize the team for their efforts

Keep on eye on the continues availability of employees ideas and make sure that is implemented

Be committed to give feedback on the implementation of Kaizen continuously and to make the

given solutions implemented according to their schedule.

Knowing that the whole company is backing you up makes it possible for you to put your whole

attention and best thinking it in to a Kaizen event.

3.3.4.3 Roles and responsibilities-The human resource manager](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-117-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Human resources should participate from the start in identifying team members and helping with pre-

training. This pre-training should occur before the event to help team members be prepared for the

changes that will take place in their work areas during and after the event. They can be given guide lines

about how to handle those changes, and how to help the co-workers do so as well.

3.3.4.4 Roles and responsibilities – Coordinator

He/she is the responsible person for the implementation of Kaizen event in the whole compound

of the enterprise.

Lead the team leaders

Has to organize the training equipment, facilities and handouts

Is the way between team leaders and executive managers

Participate in Kaizen Events as needed

Team player in application of Kaizen methodology

Provide process expertise and feedback during all Kaizen activities

Help manage implementation of solutions and ensure transition of improved process to the

business

Act as a change catalyst

He she is the responsible person for the never ending P-D-C-A circle

3.3.4.5 Roles and Responsibilities – Kaizen Lead (team leader)

Lead all Kaizen activities and facilities the Kaizen event

Train team members in Kaizen principles and techniques

Work with management to define process area, resources, and problem and goal statements for

Kaizen improvements efforts

Schedule all meetings for completing Kaizen deliverables](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-118-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Clearly define desired outcomes of Kaizen activities with management and team members

Accountable for reporting event progress and coordinating communication to management and

stakeholders

Manage implementation of solutions and ensure transition of improved process to the business

Maintain all documentation from the event, prepare and submit all deliverables

Train the team members about the Kaizen event

Keep the staff performance record sheet up to date permanently

Hand over the training need information to the training coordinator

Carry out assessment after a defined period of time

3.3.4.6 Roles and responsibilities – Team members

Participatory in all Kaizen activities(recommended number of team members does not exceed 15)

Team player in application of the Kaizen methodology

Provide process expertise and feedback during all Kaizen activities

Are responsible for tasks within the team action plan

Delivery regular updates to team and management on status of action steps

Help manage implementation of solutions and ensure transition of improved process to the

business

Act as a change catalysts](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-119-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Toyota Production System and what it means for business

TOYOTA MATERIAL HANDLING EUROPE,

MANAGING THE TOYOTA AND BT MATERIALS

HANDLING BRANDS IN EUROPE.

Introduction

This project covers starting from Toyota production system and what it means from business perspective,

Toyota material handling Europe, managing the Toyota and BT materials handling brands in Europe.

Toyota way, Toyota production system definition, and TPS history, Just-in-Time Jidoka, Kaizen, The

Environment, Health and Safety, What TPS Means for your Business the Toyota Way

This unit of competence covers the exercise of good workplace practice and effective participation in

quality improvement teams. Personnel are required to ensure the quality and integrity of their own work,

detect non-conformances and work with others to suggest improvements in productivity and quality.

Satisfy quality system requirements in daily work, Access information on quality system requirements

for own job function, Record and report quality control data in accordance with quality system, Follow

quality control procedures to ensure products, or data, are of a defined quality as an aid to acceptance or

rejection, Recognize and report non-conformances or problems, Conduct work in accordance

with sustainable energy work practices, Promote sustainable energy principles and work practices to

other workers, Analyze opportunities for corrective and/or optimization action, Compare current work

practices, procedures and process or equipment performance with requirements and/or historical data or

records, Recognize variances that indicate abnormal or sub-optimal performance, Collect and/or evaluate

batch and/or historical records to determine possible causes for sub-optimal performance, Use](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-120-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

appropriate quality improvement tools and techniques to rank the probabilities of possible causes,

Recommend corrective and/or optimization actions, Analyze causes to predict likely impacts of changes

and decide on the appropriate actions, Identify required changes to standards and procedures and

training, Report recommendations to designated personnel, Participate in the implementation of

recommended actions,Implement approved actions and monitor performance following changes to

evaluate results, Implement changes to systems and procedures to eliminate possible causes,

Document outcomes of actions and communicate them to relevant personnel, Participate in the

development of continuous improvement strategies, Review all relevant features of work practice to

identify possible contributing factors leading to sub-optimal performance, Identify options for removing

or controlling the risk of sub-optimal performance, Assess the adequacy of current controls, quality

methods and systems, Identify quality improvement opportunities to continuously improve performance,

Develop recommendations for continual improvements of work practices, methods, procedures

and equipment effectiveness, Consult with appropriate personnel to refine recommendations before

implementation of approved improvement strategies, Document outcomes of strategies and communicate

them to relevant personnel.

Toyota Production System and what it means for business

Toyota Motor Corporation is the largest automobile manufacturer (by sales) in the world. The workforce

of the company over 314,000 “To maintain a long-term vision and meet all challenges with the courage

and creativity needed to realize that vision.” KAIZEN“ Continuous improvement. As no process can

ever be declared perfect, there is always room for improvement.”

GENCHI GENBUTSU

“Going to the source to find the facts to make correct decisions build consensus and achieve goals.”

RESPECT

“Toyota respects others, makes every effort to understand others, accepts responsibility and does its best

to build mutual trust.”](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-121-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

TEAMWORK

“Toyota stimulates personal and professional growth, shares opportunities for development and

maximizes individual and team performance.”

Toyota Production System Definition

The Toyota Production System empowers team members to optimize quality by constantly improving

processes and eliminating unnecessary waste in natural, human and corporate resources. TPS influences

every aspect of Toyota’s organization and includes a common set of values, knowledge and procedures.

It entrusts employees with well-defined responsibilities in each production step and encourages every

team member to strive for overall improvement.

TPS History

Sakichi Toyoda founded the Toyoda Spinning and Weaving Company in 1918. He developed the first

steam-powered loom that could detect a broken thread and stop itself automatically. This innovation led](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-122-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

to the wider principle of jidoka, or automation with a human touch – later to become one of the two

pillars of TPS.

Some years later in 1937, Sakichi’s son Kiichiro founded the Toyota Motor Corporation. Kiichiro took

his father’s concept of jidoka and developed his own complementary philosophy – just in time –,

which would become the other pillar of TPS. He visited Ford’s mass production plants in Michigan to

study their use of assembly lines.

Taiichi Ohno

After World War II, the need to be able to manufacture vehicles efficiently was greater than ever.

Kiichiro’s younger cousin, Eiji – later to become president and chairman of Toyota Motor

Manufacturing – tasked one of Toyota’s young engineers, Taiichi Ohno, with the job of increasing

productivity.

Ohno’s achievement was to marry the just-in-time concept with the principle of jidoka. In 1953, Ohno

also visited the USA to study Ford’s production methods, but he was much more inspired by American

supermarkets. He noticed how customers would take from the shelves only what they needed at that

time, and how those stocks were quickly and precisely replenished. Ohno had the insight that a

supermarket was essentially a well-run warehouse, with ‘goods-in’ closely matching ‘goods-out’, and](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-123-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

no space for long-term storage. On his return to Japan, Ohno developed the same idea into the kanban

concept. Ohno also learnt from the American pioneer of quality control, Dr. W. Edwards Deming.

The aim of Deming’s method was to improve quality at every stage of a business, from product design,

through manufacturing, to aftersales service. Deming taught that each stage in a manufacturing process

should be thought of as the previous stage’s customer, which fitted very well with Kiichiro’s just-in-time

philosophy, and the principle of kaizen. Today, Ohno is considered the true architect of TPS, having

developed it into a practical method and, crucially, having made it work on the shop floor.

The Toyota Production System as it is today has been developed and refined over several decades.

However, the benefits that can be derived from the techniques and management processes at its heart

can equally be applied to other types of business as we progress further into the 21st century. TPS has

been implemented throughout Toyota, giving tangible benefits in the quality and reliability of Toyota’s

products and services.

The Toyota Production System has established a global reputation as a leading business philosophy that

delivers measurable benefits in terms of efficiency and quality in manufacturing. Many manufacturers

have aimed to adopt TPS principles, and academics and management consultants worldwide have

developed strategies and business improvement programmes based on TPS.

Just in Time – smooth, continuous, optimized workflows

The Toyota Production System fulfils customer demand efficiently and promptly by linking all

production activity to real marketplace demand. Just-in-time production relies on finely tuned processes

in the assembly sequence using only the quantities of items required, only when they are needed.

Imagine a process designed to produce six different types of product, where the total weekly demand for

the range of products varies up and down by 25%, and the daily mix of product types is continuously

changing.

A planning challenge, but also a typical scenario in many types of business in which the process

(manufacturing or otherwise) has to continuously respond to demand. TPS has responded to this reality

of life by developing an approach that can meet the challenge in an efficient, cost-effective way.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-124-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

HEIJUNKA – LEVELLING THE FLOW

The term heijunka describes the foundation of the TPS approach to just-in-time processes – ones in

which inventory costs are minimised by having the parts required arrive at their point of use only as they

are needed.

Unevenness in workload is known as mura. Heijunka is the elimination of mura by levelling the

volumes to allow a smooth, continuous and efficient flow. It is the opposite of mass- production series,

in which high volumes of a single product are produced, often significantly unrelated to demand.

With heijunka a process is designed to switch products easily, producing what is needed when it is

needed, and relying on production. Any variations in volumes are accommodated by establishing a

level-average demand rate.

The practice of heijunka also eliminates Muri – overburden or strenuous work that can also lead to safety

and quality problems. Both Mura and Muri are thought of as types of Muda, or waste, and should be

eliminated.

Push and TPS pull-system

ELIMINATION OF WASTE – MUDA](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-125-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Waste – defined as anything that does not add value – includes things that might not normally be

considered as waste such as overproduction, holding too great an inventory, the need for rework, and

unnecessary movement, processing and waiting.

TAKT TIME – THE HEARTBEAT OF PRODUCTION

Time planning is central to TPS. Takt is the rate of customer demand – essentially, what the market is

requiring be produced. Takt time is the term given to a work-cycle that fulfils each customer’s demand.

The key is that the work-cycle should be synchronized with demand to avoid under- or overproduction.

Takt time determines the flow-rate and allows the calculation of how much work can be accomplished.

Optimisation of takt time reduces waste and inefficiency by eliminating the risk of time delays, or excess

production, throughout the process. Takt time and heijunka mean having the ability to be flexible

according to demand and ensuring the process is smooth, continuous and measurable.

KANBAN CARD

In order to have flexibility and efficient, smooth workflows, it is necessary to have the right things at the

right place at the right time. In TPS it means having just the right components to build the product.

The kanban card is the simple, highly visible device that TPS uses to call-up components, as they are

required. This means only a minimum stock of components is held in the assembly area. Before stocks

need replenishing, a kanban card instruction from the operator ensures a just-in-time delivery. The

process is based on a ‘pull’ principle – with items called only as they are required, as opposed to a ‘push’

principle that may not take account of actual need.

Kanban card… and what it means for business

A smooth, continuous and optimised workflow, with carefully planned and measured work-cycle times

and on-demand movement of goods, reduces the cost of wasted time, materials and capacity. Team](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-126-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

members can concentrate on their tasks without interruption, which leads to better quality, timely

delivery, and peace-of-mind for Toyota’s customers.

Jidoka – building in quality

When it comes to quality, there is no room for compromise in the Toyota Production System. The TPS

principle of jidoka builds quality checks into each step of the production process. By ensuring that all

processes are visible, jidoka helps ensure that abnormalities are made visible and addressed immediately.

Andon board

Jidoka translates as “autonomation” and can be described as “automation with a human touch”. Quality

is monitored throughout, with each team member being responsible for performing quality checks before](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-127-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

delivering the goods-in-process to the next point in the production line. If a defect or error is identified it

is addressed immediately – even if this means temporarily stopping production.

GENCHI GENBUTSU – GOING TO THE SOURCE

Improvements are often made as a result of discovering problems. Therefore, problems need to be

properly understood through genchi genbutsu, which means ‘going to the source’ of the problem and

assessing it for yourself rather than relying on information supplied by others, in order to gain a

complete and accurate understanding.

ANDON BOARD

The andon board is a simple but highly-visible electronic sign displaying the status of production lines.

It notifies management immediately if a worker has identified a fault, precisely identifying its location.

Workers take responsibility for production quality, with the power to stop the production line as

required. The production line will not be restarted until the reason for the fault has been resolved.

STANDARDIZATION

Another key element for quality assurance is a focus on standardization. Developing and relying on

standardized work tasks not only ensures consistently high levels of quality, but also maintains

production pace and provides a benchmark for implementing continuous improvement.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-128-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

MISTAKE-PROOFING AND LABELING

Devices that make it difficult or impossible for a worker to make typical errors at his or her workstation

are a common sight on Toyota production lines. Known as poka-yoke, this principle is a simple but

creative and reliable way to reduce errors and maintain quality. Furthermore, all commonly used items

are clearly labelled so that they can be found and used by everyone with the same ease… and what it

means for business

Maintaining quality throughout the production process has helped to build its reputation for quality. TPS

empowers each Toyota team member to check for quality, to point out and fix any inconsistencies or

defects, and to prevent inferior quality products from being passed on to the customer. And the TPS

advantage does not end when the customer takes delivery. Toyota’s high-quality products mean

customers benefit from better productivity, less downtime and a greater return on their investment.

Kaizen – improvement is a continuous process

In many organizations, the process of change can be challenging. At Toyota change is a way of life,

thanks to the company’s fundamental philosophy of continuous improvement known as kaizen. Kaizen

means that all team members throughout the organization are continuously looking for ways to improve

operations and people at all levels in the company support this process of improvement.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-129-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Kaizen also requires clarity in terms of what is to be achieved – setting clear objectives and targets for

improvement. It is very much a matter of positive attitude, with the focus on what should be done rather

than what can be done.

TPS – THE ‘THINKING PEOPLE SYSTEM’

In TPS, team members are invited to think about the process and make timely decisions in order to keep

it running smoothly, rather than merely operating like machines. This involvement creates responsibility

for the success of the process, increasing both morale and quality. This is also essential for the success

of kaizen. Every morning an asa-ichi meeting is held to discuss quality deviations and eliminate their

causes.

Kaizen is not just based on improvements only being developed and implemented by experts or

management. Instead, it involves everybody, relying on the extensive knowledge, skills and experience

of the people working directly in the process.

For example, at Toyota Material Handling Europe’s production sites about 3,000 proposals for

improvements are made in a typical year.

TESTING THE LOGIC – ‘5 WHYS?’](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-130-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Kaizen requires the logic and benefit of all improvements to be carefully evaluated before

implementation. The concept of ‘5 whys?’ is employed to achieve this. Every planned improvement

needs to be tested by questioning ‘why?’ at five levels to ensure that the logic and value of the

improvement is clear. This reduces the risk of making changes without sufficient justification.

A CULTURE OF CONTINUOUS IMPROVEMENT – ‘5S’

The Toyota Production System goes beyond principles that are purely related to production processes. It

also extends to the whole organization – sales and marketing, administration, product development and

management.

Every employee, regardless of position, receives the same treatment. Toyota takes care to nurture a sense

of pride and efficiency in the workplace. This is supported by ‘5S’:

• SEIRI – Sifting

• SEITON – Sorting

• SEISO – Sweeping and cleaning

• SEIKETSU – Spic-and-span

• SHITSUKE – Sustain

These principles ensure that every team member is actively involved in keeping processes as effective

and efficient as possible… and what it means for business](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-131-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Kaizen is one of the foundations of the Toyota Production System – not only a process but also an

attitude. Toyota’s constant striving for improvement ensures that its customers will always enjoy

excellent products that use the most advanced and reliable technologies. Toyota also works with its

customers to achieve improvements in its services to them, to optimize their investment in Toyota

products.

The Environment – Toyota’s commitment

Throughout its wide range of activities Toyota always considers the environment as part of its daily

operations. Its policy is to analyse the effects of every stage in its products’ lives: development,

manufacturing, operation, and recycling.

TPS philosophy also includes the 3Rs – reduce, reuse, recycle. With respect to manufacturing, the

reduction of waste (muda) is one of the key principles and, therefore, benefits of TPS. Reduction of

waste in processing, inventory, conveyance, overproduction, motion, waiting, and manufacturing defects

delivers direct environmental benefits.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-132-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

At a lower level, waste sorting has long been practised at Toyota Material Handling Europe’s

manufacturing plants. TMHE’s manufacturing sites have all achieved ISO 14001 certification… and

what it means for business Toyota has a policy in place to reduce CO2 emissions, use resources more

efficiently, and reduce environmental risk factors. Considering the environment at all four stages of a

product’s life is the responsible approach and leads to real environmental benefits for Toyota’s

customers with respect to their responsibilities towards environmental issues.

TPS is concerned with Health and Safety

Safety is always the focus in all of the complementary philosophies and practices that make up TPS. Not

just a priority but a necessity. The tireless effort to do things in the best possible way could never

progress if safety were to be compromised by apparent efficiencies. When processes are improved to

increase quality, safety is also improved.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-133-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Manufacturing sites have achieved OHSAS 18001 certification – the international standard for

occupational health and safety management. They work to anticipate and reduce potential risks factors

efficiently and strive to prevent workplace accidents.

The maintenance or improvement of health, safety and ergonomy are essential when processes are

revised or new equipment is considered.

This is not new, however. TPS has always used automation and process improvement to protect workers.

The flexibility required of team members in TPS helps them to be alert and better focused as their tasks

change. In all cases, workstations are designed to be easy-to-use, making work quick, comfortable and

efficient.

As with kaizen, all team members, from management to the shop floor, participate in safety training and

in making suggestions for improvements in safety across all processes… and what it means for business

Toyota maintains health and safety for its team members so they can concentrate on their jobs delivering

the best quality products and be more efficient.](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-134-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

What TPS Means for your Business

TPS is an essential part of what makes Toyota different and makes Toyota’s products a profitable

investment for its customers’ businesses. Toyota’s customers know what to expect when they buy from

Toyota – a business partner with the strength and flexibility to meet the needs of a changing market.

• Quality inherent in Toyota’s products, thanks to the company’s constant striving for

improvement, has direct benefits for their customers…

• Costs are kept to a minimum thanks to a good return on investment based on the productivity and

reliability of Toyota’s products…

• Delivery is on time, and to the expected standard, allowing Toyota’s customers to plan and

maintain their operations successfully…

• Environmental concerns are shared by Toyota and its customers, from manufacturing through to

recycling at end-of-life. Choosing Toyota products is a good choice for the environment…

• Safety is Toyota’s constant concern – both for its employees and for those of its customers.

Toyota’s processes and products have safety built-in, with clear benefits for productivity and cost](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-135-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

The Toyota Production System – a proven excellent system– benefiting all of Toyota’s products – and all

of its clients. TPS – an Excellent System

Conceptual Overview and Definitions of Kaizen

Kaizen is a Japanese word that has become common in many Western companies. Kaizen culture an

organizational culture based on the three super ordinate principles namely process and results, systemic

thinking, nonjudgmental and non-blaming (Mullins, 2010). The word indicates a process of continuous

improvement of the standard way of work. It is a compound word involving two concepts: Kai (mean

change) and Zen (mean for the better). The term also comes from ‘Gemba Kaizen‘meaning ‗continuous

improvement‘(CI). Continuous Improvement is one of the core strategies for excellence in production,

and is considered vital in today‘s competitive environment (Robinson, 1991). It calls for endless effort

for improvement involving everyone in the organization.

Principle1: Kaizen is process oriented. Processes need to be improved before results can be improved.

Principle2: Improving and maintaining standards. Combining innovations with the on-going effort to

maintain and improve standard performance levels is the only way to achieve permanent improvements.

Here, kaizen focuses on small improvements of work standards coming from on-going efforts. There can

be no improvement if there are no standards. The PDCA Cycle (Plan-Do-Check-Act) is used to support

the desired behaviours. This cycle of continuous improvement has become a common method in Kaizen;

it is used to generate improvement‘s habits in employees. Principle3: People Orientation. Kaizen should

involve everyone in the organization, from top management to workers. One of the strongest

mechanisms aligning with this third principle is Group-oriented Kaizen. Kaizen teams focus primarily on

improving work methods, routines and procedures usually identified by management (Imai, 1986).

Kaizen Application and Implementation Kaizen implementation is not once in a month or once in a year

activity. It is continuous. Imai (1997) expressed that the rate of the worker participation in terms of

providing important suggestion for their organization and Japanese companies, (such as Toyota and](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-136-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

Canon, a total of 60 to 70 suggestions per employee per year are written down, shared and implemented).

In most cases these are not ideas for major changes. Kaizen is however, based on making little changes

on a regular basis namely, always improving productivity, safety and effectiveness while reducing waste.

Suggestions are not limited to a specific area such as production or marketing. Kaizen is generally based

on making changes anywhere that improvements can be made. A Western philosophy may be

summarized as; they say goes if it isn‘t broken, don't fix it." The Kaizen philosophy is to "do it better,

make it better, and improve it even if it isn't broken, because if we don't, we can't compete with those

who do." Kaizen in Japan is a system of improvement that includes both home and business life. Kaizen

even includes social activities. It is a concept that is applied in every aspect of a person's life. In business

Kaizen encompasses many of the components of Japanese businesses that have been seen as a part of

their success. Quality circles, automation, suggestion systems, Just-In-Time delivery, Kanban and 5S are

all included within the kaizen system of running a business. Kaizen involves setting standards and then

continually improving those standards. To support the higher standards kaizen also involves providing

the training, materials and supervision that is needed for employees to achieve the higher standards and

maintain their ability to meet those standards on an on-going basis. Kaizen is focused on making small

improvements on a continuous basis (Imai, 1997). Many scholars in the field believe that there are

certain minimal conditions which have to be met for successful implementation of kaizen. This includes

conducive political framework, harmonious social relations, compassionate and sympathetic attitude, and

capacity to take individual, as well as collective responsibility, and ability to work collectively or high

social capital (Ohno, I., Ohno, K., Uesu, S., Ishiwata, A., Hosono, A., Kikuchi, T., et al., 2009)

The System, Technique and Implementation of Kaizen Family

Indeed an integral part of Total Quality Management (TQM) is Kaizen therefore the term is

reciprocally related. When an organization/company want to maintain a level of quality that satisfy their

customers at the appropriate time and price then that organization must follow some quality management

techniques to fulfill those principles and planning. According to Imai (1986) the techniques associated](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-137-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

with Kaizen included are, total quality control (TQC)/TQM, just in time (JIT), total productivity

maintenance (TPM), five ‖s‖ (5s), Benchmarking, skill gap analysis, six sigma the information about it

found under TQM, Policy Deployment, a Suggestion System, Small-group activity, etc. For this research

only use some of them than all organizational performance and effectiveness.

Under Organizational performance and effectiveness also it has, TQM/Kaizen, Six Sigma and BPR are

the meagre ones according to (Mullines, 2010). These are generally expressed in terms of a way of life

for an organization as a whole, committed in total customer satisfaction through continues process of

improvement or an application of radical change, and the contribution and involvement of people. This

topic also emphasize on explanation about the features of TQM and kaizen in detail.

Total Quality Management (TQM)

One particular approach to improved organizational performance and effectiveness is the concept of the

Japanese inspired total quality management (TQM). There are numerous definitions about TQM. These

are generally expressed in terms of a way of life for an organization as a whole, committed to total

customer satisfaction through a continuous process of improvement and the contribution and

involvement of people according to (Mullines,2010)5. A major influence on the establishment and

development of TQM was the work of Deming, who emphasized the importance of visionary leadership

and the responsibility of top management for initiating change. A mathematician by training, he was

interested in statistical measurement of industrial processes and attempted to persuade the American

manufacturing industry to improve quality, and to create constancy of purpose for improvement of

products and service. Deming cited in, (Ibid), drew attention to the importance of pride in work and

process control, and made constant reference to the importance of ‗good management‘ including the

human side of quality improvement and how employees should be treated. The successful organization

should perform effectively with organizational matter on policy issues it is constantly seeking

opportunities to improve the quality of its products and/or services and processes. The organization must

also couple quality with a required level of productivity. The chartered management institute gives the

following definition: (Ibid: 782.) TQM is a way of managing which gives everyone in the organization

responsibility for delivering quality to the final customer; quality being described as ‗fitness for purpose‘

or as ‗delighting the customer‘. TQM views each task in the organization as fundamentally a process](https://image.slidesharecdn.com/kaizenberhanutadesstayeedited-211005180132/75/Kaizen-berhanu-tadess-taye-edited-138-2048.jpg)

![[ T y p e t h e c o m p a n y a d d r e s s ]

which is in a customer/supplier relationship with the next process. The aim at each stage is to

define and meet the customer‘s requirements with the aim of maximizing the satisfaction of the

final consumer at the lowest possible cost.

Implementation of TQM and Kaizen

If TQM is to be implemented successfully it must be seen as a total process involving all operations of

the organization and the active participation including top management. It demands a supportive

organizational culture and a programme of management change. TQM places emphasis on the

involvement of people as

the key to improved quality. It involves changes to the traditional structure with greater emphasis on

natural 5 Laurie J. Mullins is lecturer in Portsmouth University of United Kingdom (UK) he wrote a book Management and

organizational Behavior, the TQM information can get in the themes of organizational performance and effectiveness. work

groups, multi-discipline working and team-based management. Attention must be given to effective

education and training, empowerment and the motivation to take ownership of quality, and systems of

communications at all levels of the organization. A related strategy to achieve a long-term aim, hence,

management authors‘and researchers agreed that the successor of TQM is the balanced scorecard.