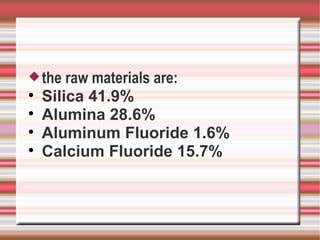

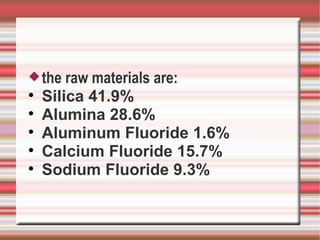

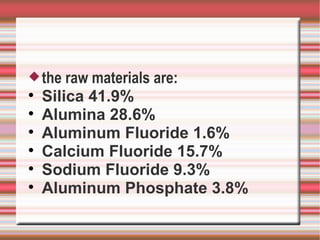

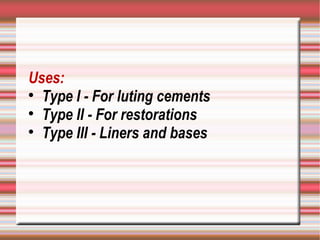

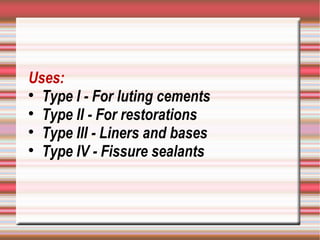

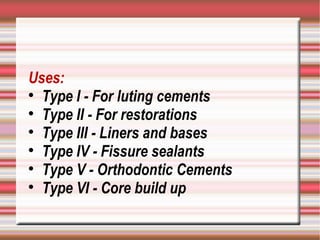

Glass ionomer cements were introduced in 1972 as tooth-colored restorative materials that bond chemically to dental tissues and release fluoride over time. They are classified into conventional, resin-modified, and metal-reinforced types. Glass ionomer cements set via an acid-base reaction between a fluoroaluminosilicate glass powder and an aqueous polyalkenoic acid liquid. They offer advantages like adhesion, fluoride release, and marginal sealing but are also brittle and soluble. Glass ionomer cements are used for luting, restorations, liners, fissure sealants, orthodontic applications, and core buildups.