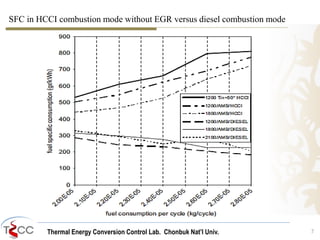

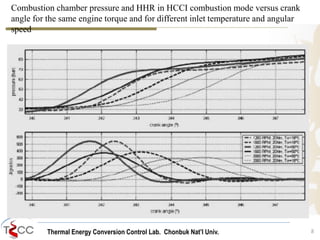

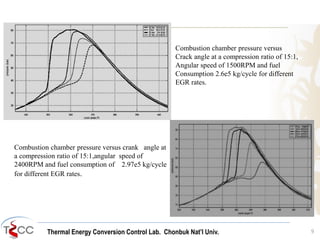

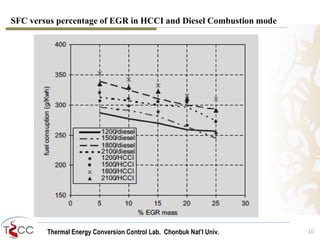

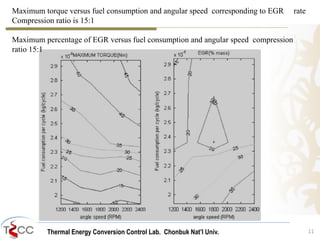

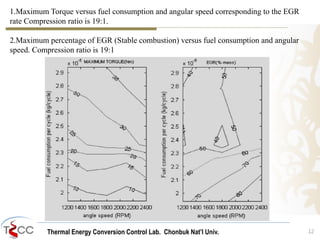

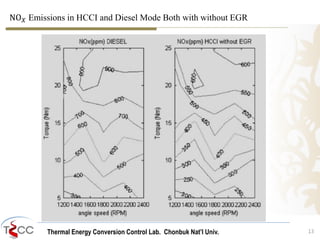

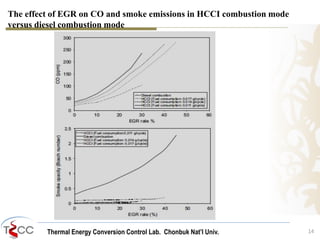

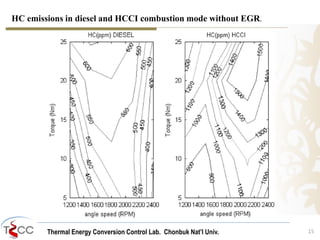

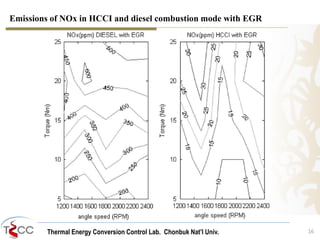

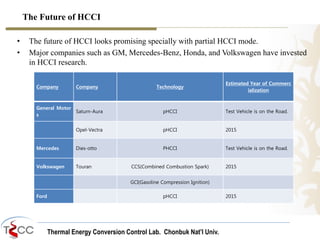

This document summarizes an experimental study of a modified diesel engine operating in homogeneous charge compression ignition (HCCI) combustion mode compared to the original diesel combustion mode. The study found that HCCI combustion provided very low NOx and soot emissions but had challenges with hydrocarbon emissions, fuel consumption, ignition timing control, and performance at high loads. Cooled exhaust gas recirculation was used to control in-cylinder NOx production. Test results showed significant reductions in NOx and smoke emissions for HCCI combustion compared to diesel mode, along with generally higher hydrocarbon and carbon monoxide emissions due to early fuel injection timing and fuel adhering to cylinder walls.

![References

[1] Kimura S, Aoki O, Ogawa H, Muranaka S, Enomoto Y. New combustion concept for ultra-clean and

high-efficiency small DI diesel engines. SAE paper 1999- 01-3681, 1999.

[2] Ogink R, Golovitchev V. Gasoline HCCI modelling: computer program combining detailed

chemistry and gas exchange process. SAE 2001-01-3614, 2001.

[3] Zhao H, Peng Z, Ladommatos N. Understanding of controlled autoignition combustion in four-stroke

gasoline engine. Proc Inst Mech Eng 2001; 215(Part D):1297–310.

[4] Palomar JM, Cruz F, Ortega A, Jime´nez-Espadafor FJ, Martinez G, Dorado MP. Development of a

computer model to simulate the injection process in a rotary injection pump. Energy Fuels 2005;

19:1526–35.

[5] Thring RH. Homogeneous charge compression ignition (HCCI) engines. SAE paper no.

892068, 1989.

[6] Christensen M, Johanson B, Ammeus P, Mauss F. Supercharged homogeneous charge compression ig

nition. SAE paper no. 980787, 1998.

[7] Nebjosa Milovanovic, Rui Chen. A review of experimental and simulation studies on controlled auto-ignition

Thermal Energy Conversion Control Lab. Chonbuk Nat’I Univ.

19

combustion. SAE paper 2001-01-1890, 2001.

[8] Lu¨ Xingcai, ChenWei, Ji Libin, Huang Zhen. The effects of external exhaust gas recirculation and

cetane number improver on the gasoline homogeneous charge compression ignition engines. Combust

Sci Technol 2006;178: 1237–49.

[9] Aceves SM, Flowers DL, Westbrook CK, Smith JR, Pitz WJ, Dibble R. HCCI combustion and

emissions. Paper no. 2000-01-0327.](https://image.slidesharecdn.com/20141203-141215013353-conversion-gate02/85/20141203-19-320.jpg)

![[10] Yoshiaki Nishijima, Yasou Asaumi, Yuzo Aoyagi. Premixed lean diesel combustion (PREDIC)

using impingement spray system. SAE paper no. 2001-01-1892, New ACE Institute Co, Ltd.

[11] Hashimoto K, et al. Evaluation of ignition quality of LPG with cetane number improver. SAE

technical paper no. 2002-01-0870, 2002.

[12] Shimazaki N, Akagaka H, Tsijimura K. An experimental study of premixed lean diesel combustion.

SAE technical paper no. 1999-01-0181, 1999.

[13] Heywood JB. Internal combustion engine fundamentals. Singapore: McGraw- Hill Book Company

; 1998.

[14] Taylor Charles. The internal combustion engine in theory and practice. Cambridge, MA:

Massachusetts Institute of Technology; 1966.

[15] Maiboom A, Tauzia X, He´ tet JF. Experimental study of various effects of exhaust gas

recirculation (EGR) on combustion and emission of an automotive direct injection diesel engine. Energy

2008;33: 22–34.

[16] Torres Garcı´a M, Chacartegui Ramı´rez R, Jime´nez-Espadafor Aguilar FJ, Sa´nchez Lencero T.

Analysis of the start of combustion of a diesel fuel in a HCCI process through an integral chemical

kinetic model and experimenta- tion. Energy Fuels; 2008; ASAP article; DOI:10.1021/ef700541z.

[17] Lei Shi, et al. Study of low emission homogeneous charge compression ignition (HCCI) engine

using combined internal and external exhaust gas recirculation (EGR). Energy 2006;31:2665–76.

[18] Egnell R. The influence of EGR on heat released rate and NO formation in a DI diesel engine. SAE

paper no. 2000-01-1807, Society of automotive Engineers Inc., Warrendale, PA, 2000.

[19] Yoshiaki Nishijima, Yasou Asaumi, Yuzo Aoyagi. Premixed lean diesel combustion (PREDIC)

using impingement spray system. SAE paper no. 2001-01-1892, New ACE Institute Co, Ltd.

Thermal Energy Conversion Control Lab. Chonbuk Nat’I Univ. 20](https://image.slidesharecdn.com/20141203-141215013353-conversion-gate02/85/20141203-20-320.jpg)