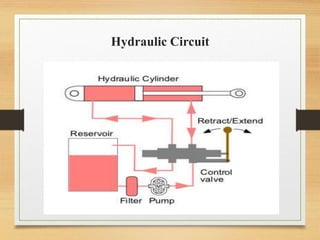

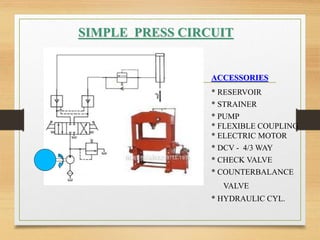

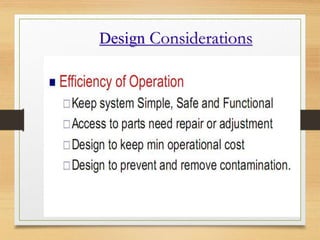

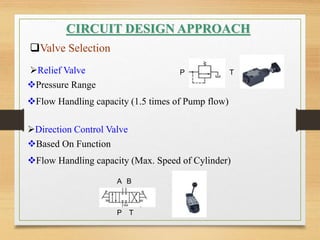

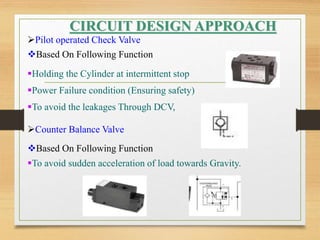

This document discusses the basic design process for a hydraulic circuit. It outlines several key designer considerations including the size of actuators based on output objectives, the sequence of operations, method of control, operating pressure, and special requirements. It then provides an example of a simple press circuit layout. The document goes on to describe the circuit design approach, including determining specifications, selecting the appropriate size cylinder, pump, electric motor, reservoir, valves, and other components based on the job requirements and flow needs.