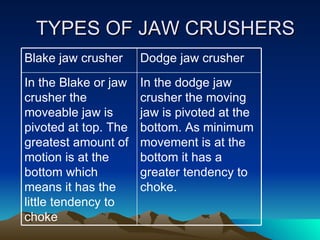

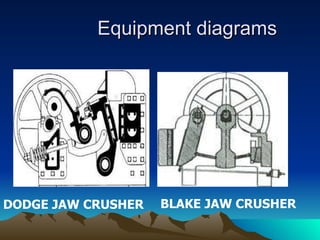

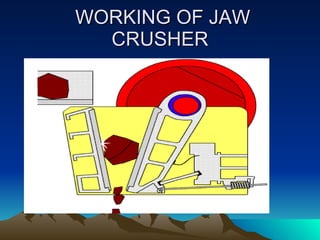

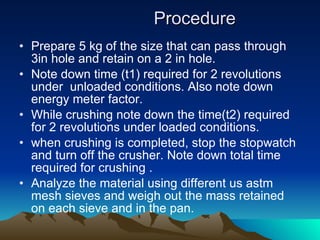

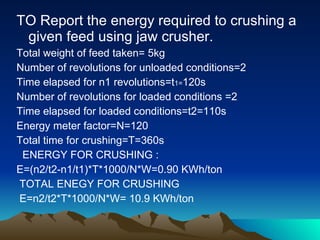

The document describes the components, working principle, types, applications and features of a jaw crusher. It discusses the Dodge and Blake jaw crushers, which differ in the pivot point of the moving jaw. An experiment is described to calculate the energy required to crush a 5 kg feed sample in a jaw crusher and determine the particle size distribution of the crushed product.