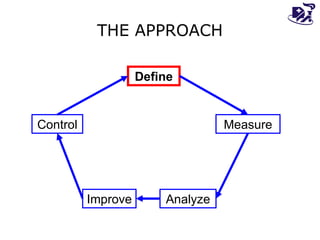

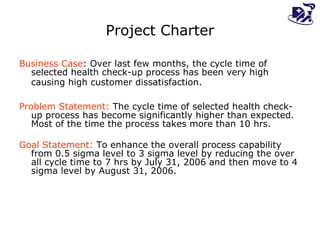

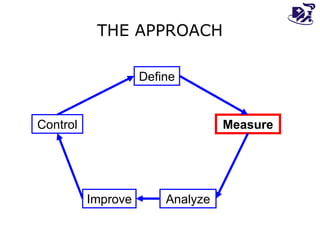

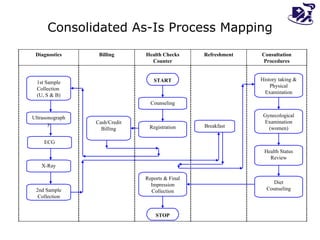

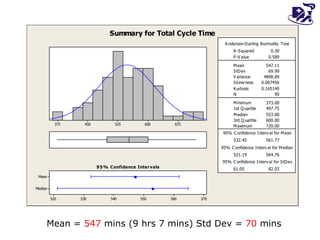

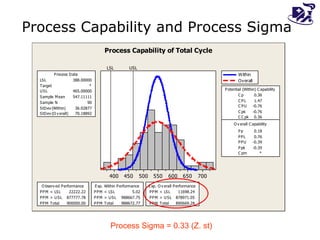

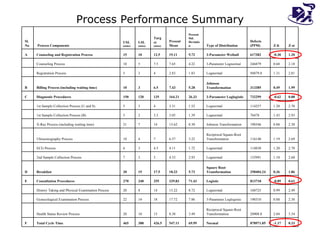

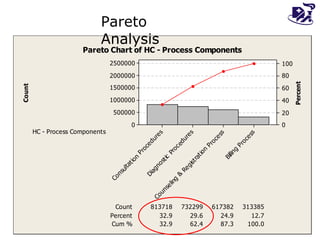

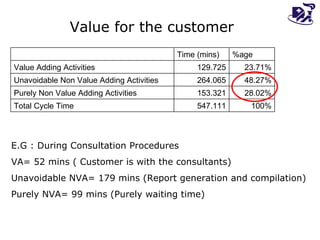

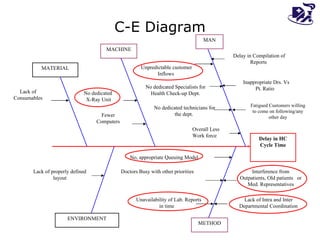

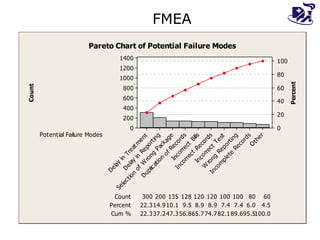

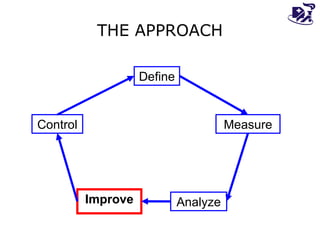

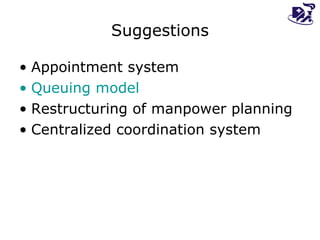

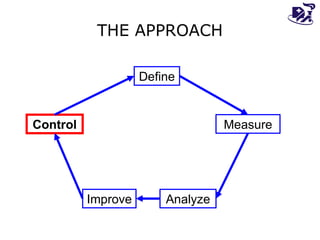

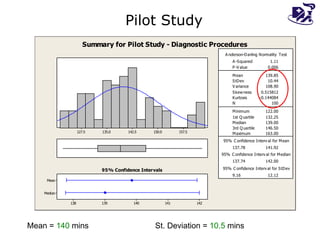

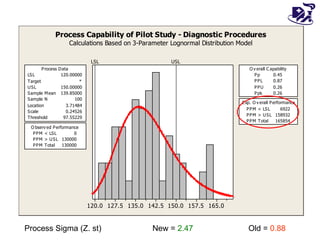

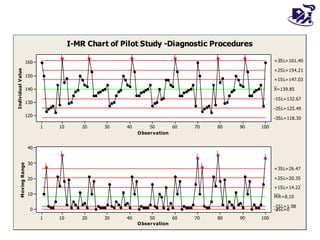

This document summarizes a study using Six Sigma to optimize the process of a health check-up package. The current process takes an average of 9 hours and 7 minutes with high variation. The goal is to reduce the cycle time and variation to meet customer expectations of 7 hours or less. Process mapping and data analysis identified sources of waste and non-value-added activities. Suggested improvements include implementing an appointment system, queue modeling, and restructuring resources to centralize coordination and improve workflow. A pilot test achieved a cycle time of 2 hours and 40 minutes with lower variation, showing potential for further optimization.

![THANK YOU [email_address]](https://image.slidesharecdn.com/isps2007-12604596587742-phpapp01/85/ISPS-2007-26-320.jpg)