This report presents an analysis of forging defects in automobile components using Deform 3D software, focusing on material flow issues such as unfilling. The research emphasizes the importance of billet positioning and temperature limits to optimize forging processes, particularly for an ST 52/3 steel end plate. Simulation results demonstrate the successful identification of optimal positioning ranges and temperatures to minimize defects during forging.

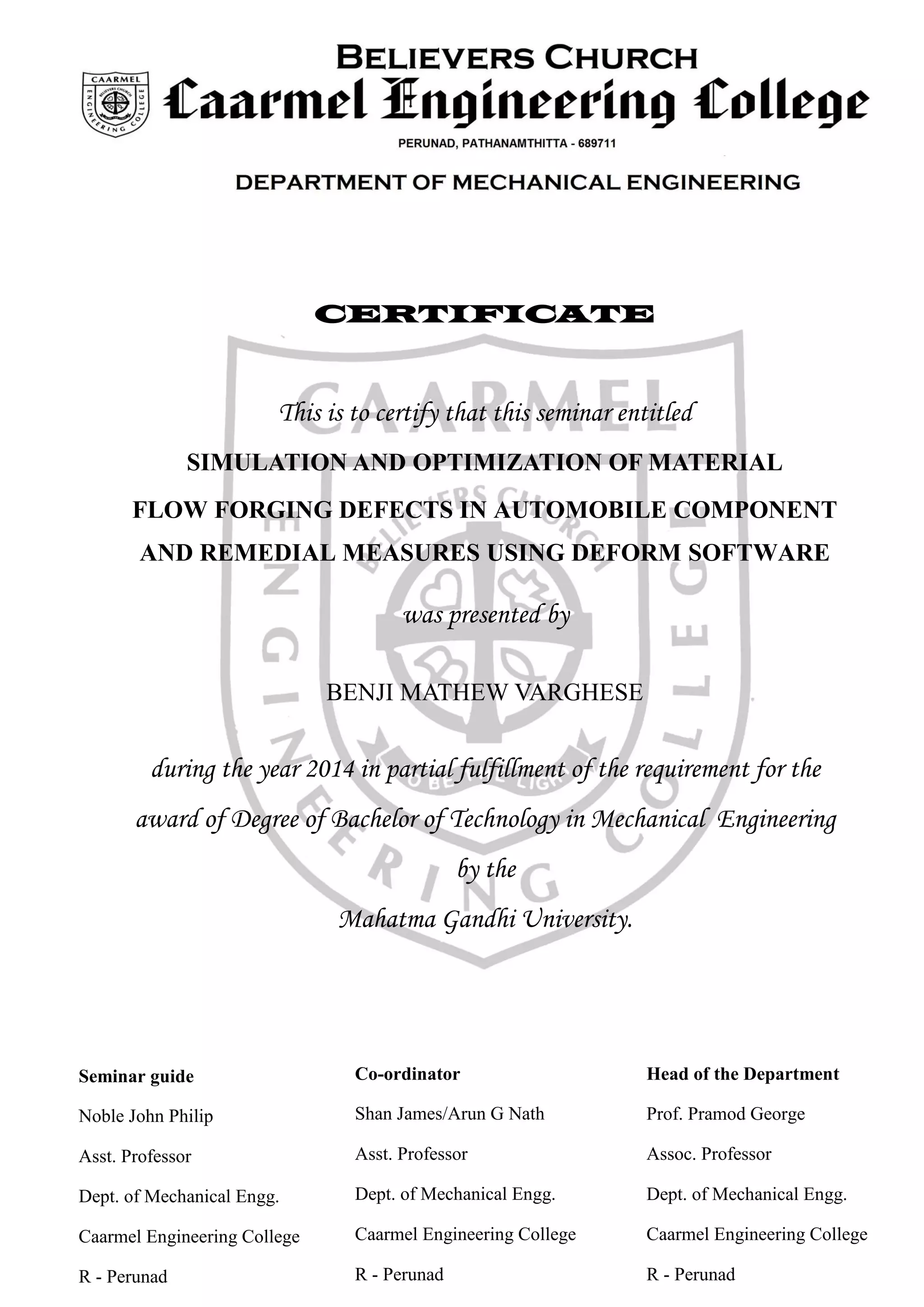

![S No. Temperature (°C) Observations

1. 1200 Completely Filled

2. 1000 Partially Unfilled

3. 900 Partially Unfilled

Table 6.2 shows the results of simulation based on different temperature of the workpiece

on the bottom die during forging process.

6.1.3 DESIGN OF EXPERIMENTS RESULTS

F-test is based on F-distributions and is used to compare the variance of two

independent samples or factors. This test is also used in the context of Analysis of Variance

(ANOVA) for judging the significance of multiple correlation coefficients. [4]

The operating variables considered in this experiment are Position along X axis (X) and

Position along Y axis (Y). The output variable is the scrap volume. With each set of

combinations of the operating parameters the resultant volume changes. Here we will

optimize the output scrap volume. The scrap volume is calculated by subtracting the volume

of the final component (end plate after trimming) from the total volume (i.e. volume of the

end plate including that of the flash)

Table 6.3 shows the different levels of the operating parameters (X & Y)

Table 6.4 shows the set of combination of these parameters at which different experiments

are performed.

Parameters Level 1 Level 2 Level 3

X (mm) -195 -190 -185

Y (mm) 170 175 180

S No. Combinations of Parameters

X (mm) Y (mm)

1. -195 170

2. -195 175

3. -195 180

4. -190 170

5. -190 175

6. -190 180

7. -185 170

8. -185 175

9. -185 180](https://image.slidesharecdn.com/seminarreportfinal-150423032832-conversion-gate01/75/SIMULATION-AND-OPTIMIZATION-OF-MATERIAL-FLOW-FORGING-DEFECTS-IN-AUTOMOBILE-COMPONENT-AND-REMEDIAL-MEASURES-USING-DEFORM-SOFTWARE-22-2048.jpg)