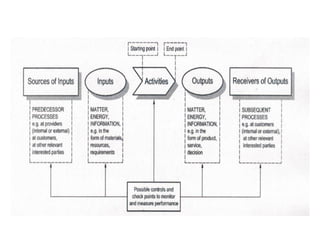

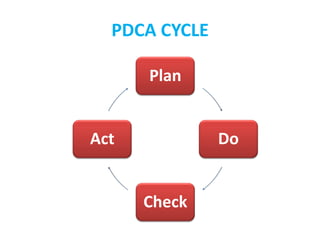

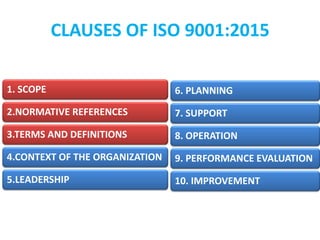

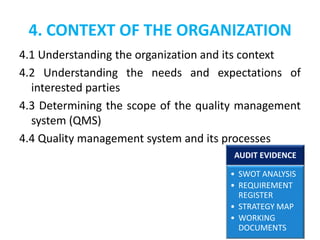

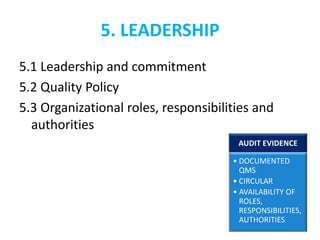

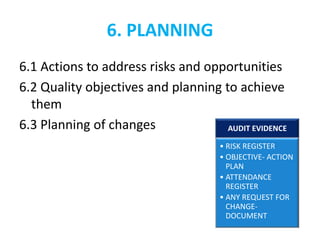

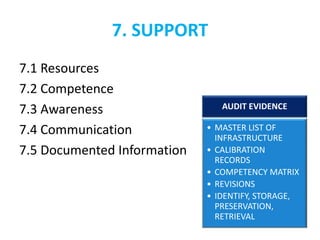

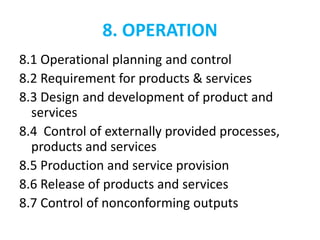

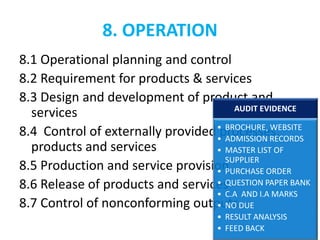

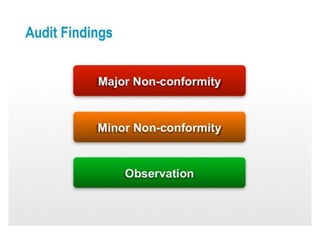

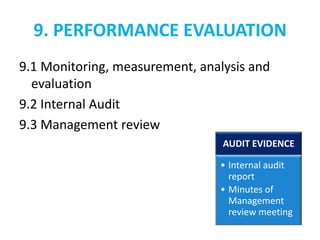

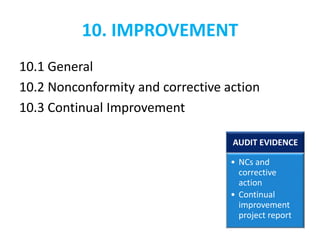

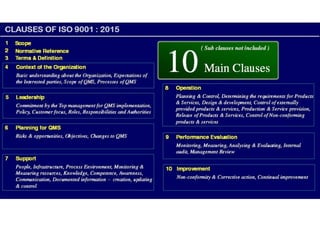

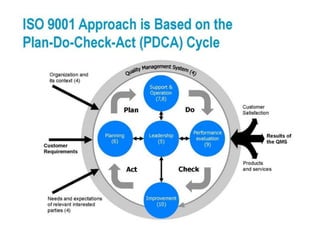

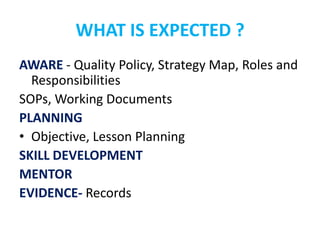

This document provides an overview of ISO 9001:2015 requirements for quality management systems. It describes the quality management principles, PDCA cycle, risk-based management approach and the 10 clauses of the standard. Each clause is broken down into requirements and examples of evidence that would be audited to ensure compliance. Organizations must understand the standard, plan how to implement it, and provide evidence that key processes are documented, monitored and improving in order to achieve certification.