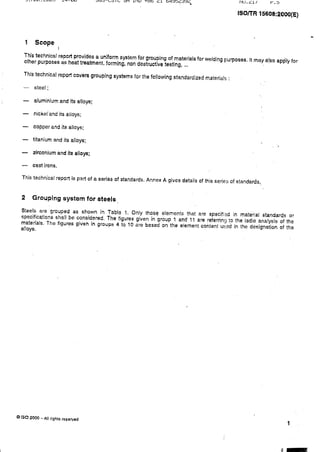

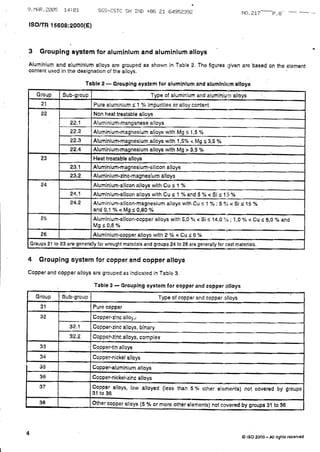

This document provides guidelines for a uniform system to group metallic materials for welding and other purposes. It defines grouping systems for steels, aluminum and its alloys, nickel and its alloys, copper and its alloys, titanium and its alloys, zirconium and its alloys, and cast irons. The groupings are based on elemental composition ranges specified in material standards and designations. Tables 1 through 3 define the grouping systems for each material class.

![ISO/TR15608:2000(E)

Foreword

Tho text of CR lso iseog:zooo-hae beenproparedby Technicalcommittse0ENfiC 121.,welding,,,the

secretatiat.ot whichis held by DS, in collaborationwith TechnicalcommifteeIS()/TC44 'Weldingani iffiua

processee".

ThisCENReponsupersedesCR12187:19S5

Accordingto.thd CEN/CENELEChternalFtegutations,the nationalsrandatdso.gAnizationsof the following

coudries_arebgundto implernentthisEuropeanStandafd:Aq€lfia,Belglum,Czechhepublic,Deninark,Finland]

France,Germany,Greece,lceland,lreland,Italy,Luxembourg,Netheriands,Nonrvay,i'ortugal,spain, sweJen,

SwitzerlandandrheUnit€dKingdom.

Q f8OZ0oo- Allrightsreseved](https://image.slidesharecdn.com/iso15608-2000welding-150422022820-conversion-gate02/85/Iso-15608-2000-welding-_guidelines_for_a_metallic_material_grouping_system-4-320.jpg)

![9. f'1RR.2005 14: AI SGS_CSTCSH IND +85 ?T 6495?39" NO.217-P. 9*

*

lso/TR1560812000(E)

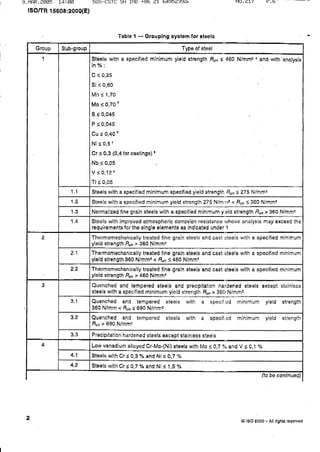

5 Groupingsystemfor nickelandnickelalloys

tl]g!g]a3onickeralroysqr: gro-upedasindicEtedinrabrE4. ThefiguresgivsnErebasedontheeremEntcanrentusedinthed6signationofthealloys.

Tabfe4 - Grouplngsystemfor nickelandntckelalloSr,s

6 Groupingoystemfoqtrtaniumandtitaniumailoys

Titaniumandtitaniumalloysaregroupedasindieatedin tables.

5

Group l m l

Typeof nickelandnickelalloyri

Pureniokel

''rl

nt,-.-__. r | |

Nickel-copperalloys(Ni-Cu)Ni> 45lo,Cui 1Qyo

iln

Nickel-chromiumalloys(Ni-Cr-Fe-Mo)Ni>40y,

-",t

Nickel-molybdenurnalloys(Nl-Mo)Ni> 4s7o,Mos gz%

' t - . r l l

Nickel'iron-chromlumalloys(Ni.Fe-cr)Ni>go%

- I ,.

i

Nlckel'chrornium-cobaltalloys(Ni-cr-co)Ni> 4sro,co > 1l)y"

ill

Nickel-iron-chromium-copperalloys(Nl-Fe-Cr-Cu)Nia 4sld,

-----l

I

41

42

43

44

4s

46

47

48 Nickel'iron'cobaltalloys(Ni-Fe-Co-Cr-Mo.Cu)ps % s Ni < dlsa/aendFe > po o/^

Table5 - Groupingsystemfor titaniumandtitaniqmalt,tirvs

Sub-group Typeof titaniumandfitanlumalloii,s

Puretitanium

Titaniumwirh02 < O,ZO"/a

Titaniurnwith0,20o/"< Oz3 0,25"/o

TitqnlumwithO,Z5"h < OzE o,gs"/o

T{tanlumwith0,BS1L<Ozs O,4O%

Alphaalloys'

Alpha-betaalloysb

Nearbetaandbetaalloys" ,

,,r".i[i]:.""""r"0bysroups2ars:rlo,zpdirl2,scutii.sAE"ss;E;ffiffi.;,ifriitil-1'6^FrNb

"

Alloyscoveredbygroup53Ere;Ti-3Al-2,5v;Ti-sAt.4V;Ti-6Al-5V-2SnI Ti.7Al-aMo.

l;Ti.11,5Mo-6Zr.4,5Sn;Ti.3At.8V.6Cr.4Zr.4Mo.

@ISOeoOO- All rightsreseryed](https://image.slidesharecdn.com/iso15608-2000welding-150422022820-conversion-gate02/85/Iso-15608-2000-welding-_guidelines_for_a_metallic_material_grouping_system-9-320.jpg)

![0

e

.:J

0)

o

()

II

CD

a

to

u)

l-

_ o

N '

ta

LO

o

a

zl r t

iij,'tsF!',

F R ;(o (E

tr)U)

O O

tr) v)

z ;lrl l!

: ( t l O .

F f r ]

( o ( o

tr) lf)

o o

g,e,

z zU'l IJJ

o

N

(o

to

o

a

2

IJJ

trt

o

F

(/)

d

9.

CE

rt)

|.n

t4

q

oU)

z

LU

F l f i l

r ( )

(o!CI

t(, st

o o

4 6 ,

z z

ul ur

(Y) lo

r- t-l)

(D r{)

ul rf

o o

9 o

z zuJ [l

rn

lft

ta

-i|

oU)

z

IJJ

,c

!

gJ

c.)(J

$

v,'ol-

' e

cr

'ili'i#lb.

,;f:j{'f

';;i

ro,g)

o(o

ln

oq

z

l.l,l

rl.),:),

i:.:ii

'l'dr

tr"

,i ?.

ffME

ilfi

l#'rH

it{rlti

x--

;bt

ffi,rl:.

$:i'r.4:.

r : , {

'l!,

l

!At 'ii

il

ffil 9

( E E

F E

o(0

t

IE

{1

ig

o

ll

F

a

E

t0

e

d

qt 3

FIH-l c/)

4ls

.?lE

ffi{

t3l

E

o

B

E

(q

o

.4t

OJ

g)

$

t-I

II

Y l ,cD 1.1

c ) I i

( o t :

l,' [1

5 l rcn l:i

A[i nf

ilH/,/

F

og

I

UJ

a

t)

Q o

r . c

= 3t r o )

6 !

il

3 l lo V ;

E ll.ir f $

o [,1

u, ftlt

; lliur li,I

:f;;;

.ll!

l:,iJ

).-:i

?tit

f,iii

rilll

i:ir5

r:i1

iri'. I

i:'ii

li r:

1l

r-

o

2

L

U

Er

E;:

B

U'

(!

o

t 8|t s I

l tI L

l ll l l

l l j

qt

d)

Cf

(9

lJ)

o

L

z

IJJ

a

o

o

zl ? r

l,/

E

+ l # . c f l

F I E , Eh i

5l#Es-H9 l - v ; O ' *

= l 1 1 c E E

_ f l f l f e { ^

'15

cJ

e

I

of

a

7

JJ

€ F F "^ . 3 - H B , f ; 'I E E

flgsaEEESCsSlll- C'i# +' .E ,:.irjj Fr *i +; I

f iF { = E E , i E F n = e i E

l t 4

n l i

$ l E

I E

, E I

o. I

g l

o ) l'rnr E I

; d l ?

€ E t *

Eh l =q l

c ) l

T r l

o l

.n

o

qJ

E

UI

c

o(,

'rt

q)

oL

ct

a'.

l oI L

EtlEFrlEo.=lE| (t)

q

a

C

, 9

o

:

CL

I

E

E

I

t a

l q )

t 9 )

0)

u

o

q.

U7

,tr

E

E

ts

9. rlFR.?8A= I4tA? SGS_CSTCSH II.ID +86 ?L 54952392 f.to.e17-p. rr

ISO/TR15608;2000(E)

to

oL

I

t

c(J

tr)F

-

g

o

B

F

0

E

o

q

CL

o

E

c

fiI

s

L

o

1F

af

(,

.=(,

ttn

A

E

3

tr)

ct=

t5

q,

TI

q,

tt

l

f t t l

i E I

f t

G i

E l

a l

f l

; tE I

6 l

? lt l' l

T I

o l

E I

, G t

F I

it

oL

El.

o,(E

E

c(!

c

a4Fr

F

(!

()

a -

I-

'd

o

a.

o' F

-1,-

'E

ct)

e q

= o( t r L _

o =

E l t

- a P

x

o * c L"

= c E )

e g,-E- srtt

O E

s e+ a -

.L iF

6 o

3-$

rF

o

a

I

F

F

q)

*t

q

q

g)

ca -

L

o

.cl

trlr

-J

F

L

-

o

Z -

o)

. l . H

(tr

. . 1 .

oq)

u)

@ISO20oo- Allrightsreserved](https://image.slidesharecdn.com/iso15608-2000welding-150422022820-conversion-gate02/85/Iso-15608-2000-welding-_guidelines_for_a_metallic_material_grouping_system-11-320.jpg)