This document summarizes revisions made to the Chinese national standard GB/T 3077-1988 "Alloy Structure Steel". Key changes include:

- Renaming the standard to "Alloy Structure Steel"

- Allowing bar stock diameters greater than 250mm to be provided

- Adding chapters on "Order Content" and unified digital codes for steel grades

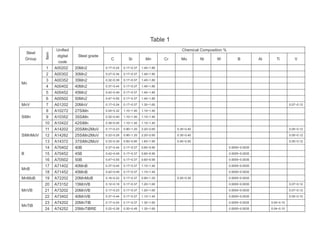

- Canceling and adding certain steel grades

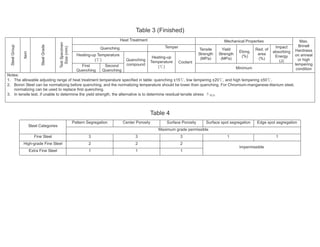

- Adding limits for molybdenum content and deleting some clauses

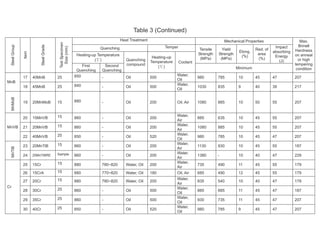

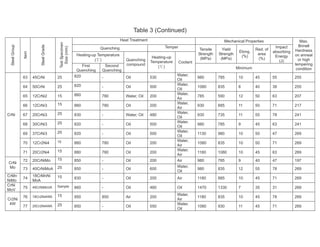

- Adjusting heat treatment processes and parameters for individual steel grades