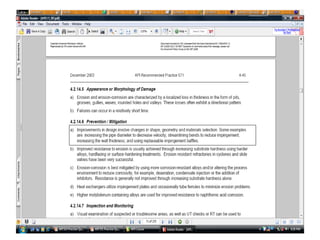

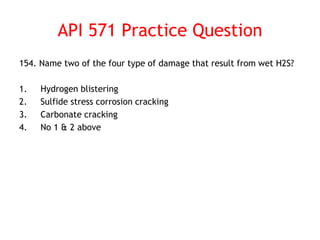

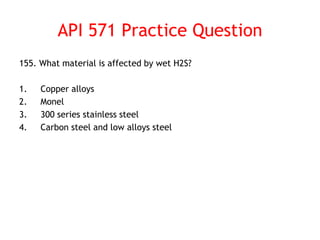

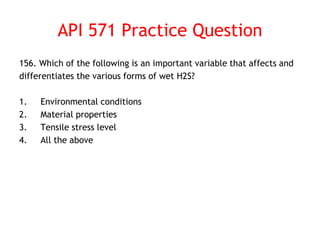

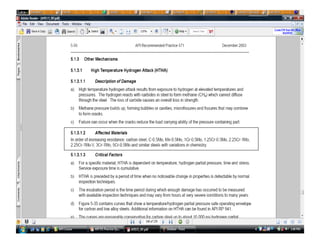

This document contains 162 multiple choice practice questions related to various damage mechanisms that can affect fixed equipment in the refining industry, including temper embrittlement, brittle fracture, thermal fatigue, corrosion, erosion, mechanical fatigue, stress corrosion cracking, hydrogen damage, and high-temperature hydrogen attack. The questions cover definitions of damage types, materials affected, appearance of damage, factors influencing damage, inspection techniques, and methods for prevention or mitigation.