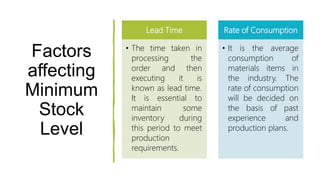

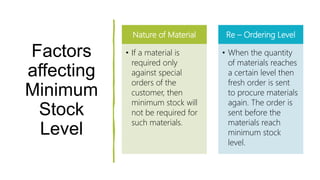

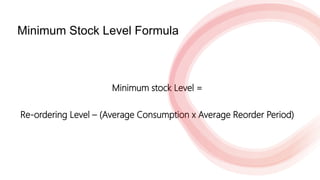

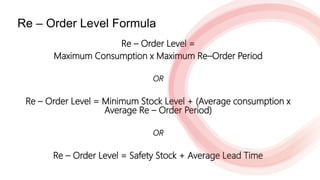

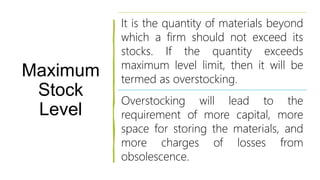

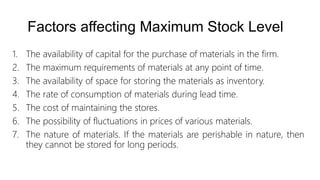

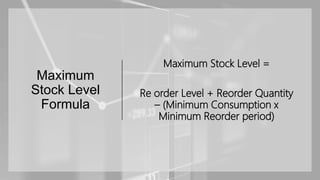

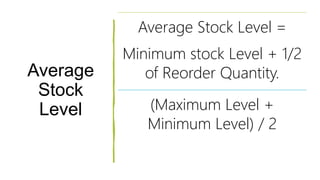

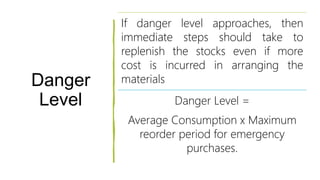

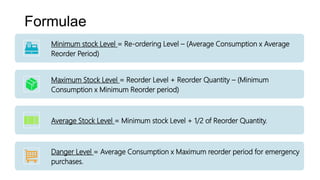

This document discusses key concepts in inventory management including minimum stock level, reorder level, maximum stock level, average stock level, and danger level. The minimum stock level is the quantity that must always be maintained, and if stocks fall below this level then production will stop. The reorder level is the quantity at which a fresh order is placed, and there are formulas to calculate the reorder level based on factors like average consumption and reorder period. The maximum stock level is a limit beyond which excess inventory is considered overstocking, and average stock level is calculated as the midpoint between minimum and maximum levels. The danger level indicates when immediate replenishment is needed.