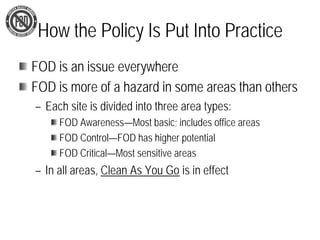

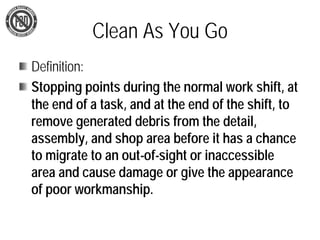

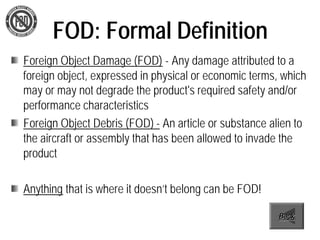

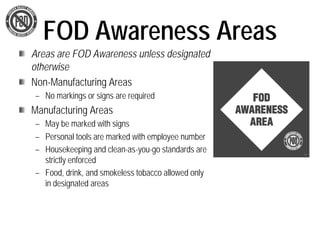

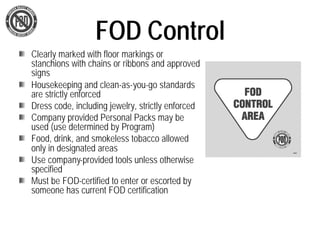

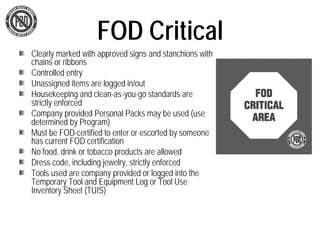

This document discusses foreign object damage (FOD) prevention. It defines FOD and outlines a company policy to design and deliver FOD-free products. The company's facilities are divided into three areas - FOD Awareness, FOD Control, and FOD Critical - with increasing restrictions based on FOD risk. Everyone must follow clean-as-you-go practices and FOD prevention procedures appropriate for the area. Visitors to manufacturing areas may need an escort and to follow area-specific guidelines. The overall goal is to prevent any foreign objects that could damage products or systems.