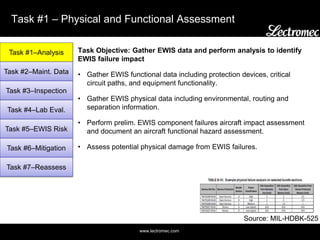

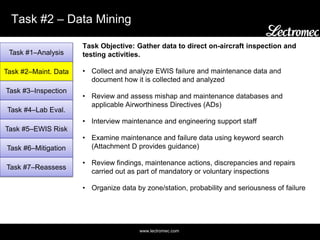

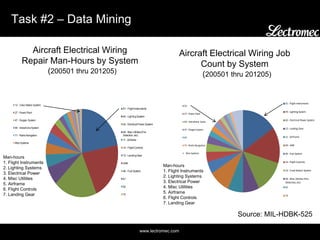

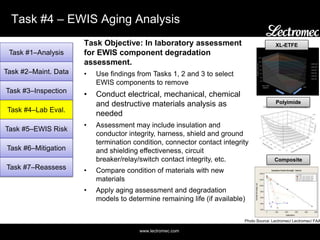

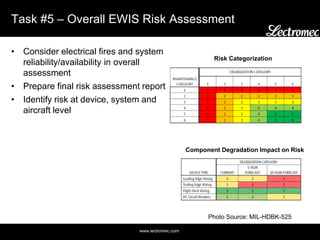

The document provides a comprehensive handbook on assessing the condition and service life extension of Electrical Wiring Interconnection Systems (EWIS) in military aerospace platforms. It outlines a structured approach, detailing seven key tasks including data collection, physical inspections, aging analysis, risk assessment, and action planning to ensure continued airworthiness. The guidance aligns with military standards and aims to create consistent methodologies for fleet management and safety assessments.