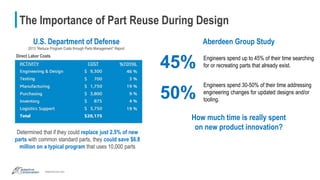

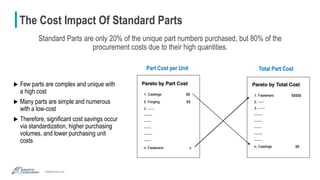

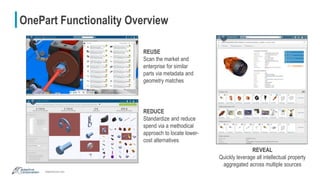

The document discusses the importance of part reuse and standardization in reducing costs within the product lifecycle, specifically highlighting that replacing just 2.5% of new parts with standard parts can lead to significant savings. It emphasizes the inefficiencies engineers face due to fragmented data and the need for integrated systems. The Exalead OnePart tool is introduced as a solution for improving part searching and reducing duplicate parts across engineering databases.