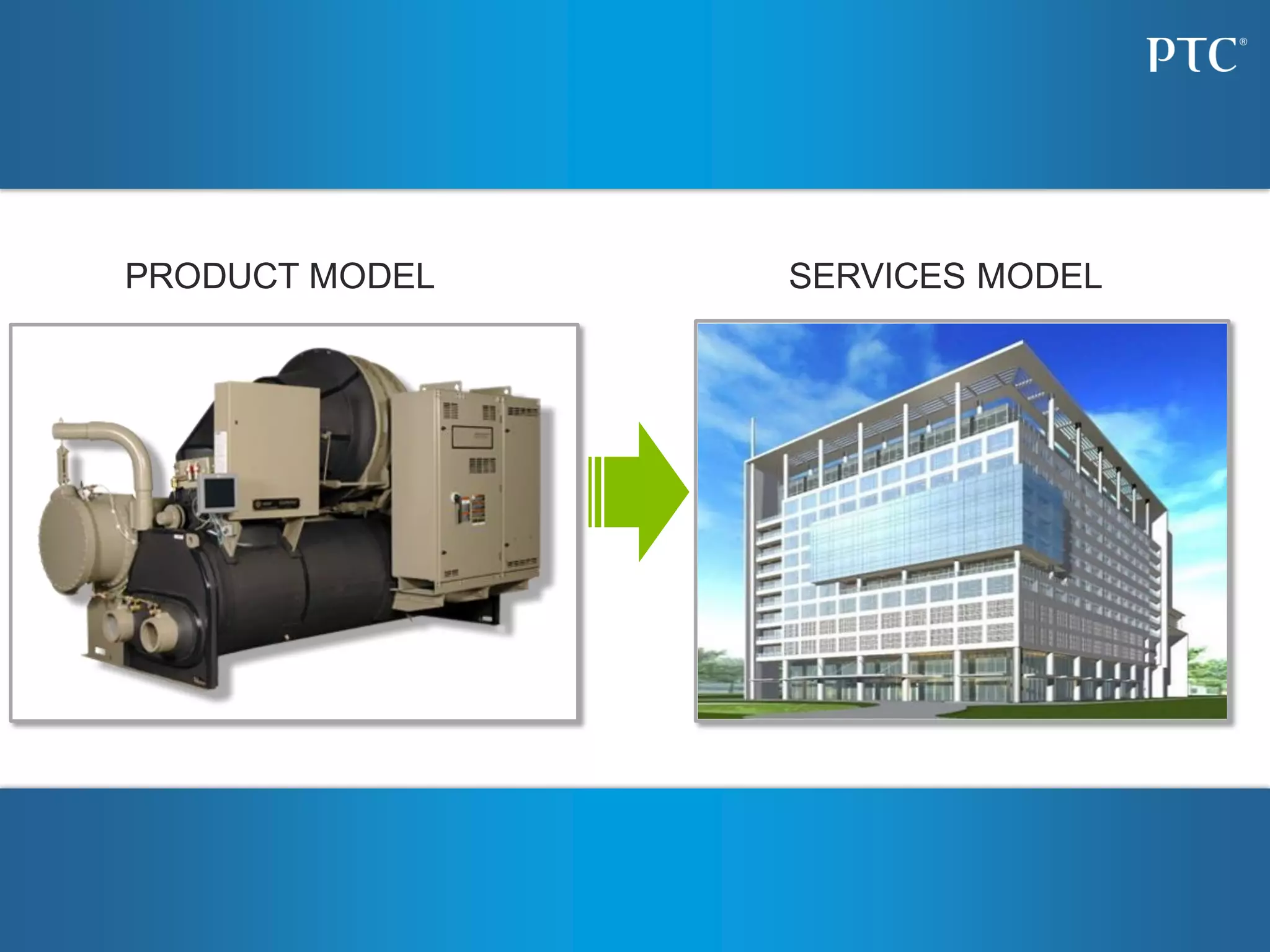

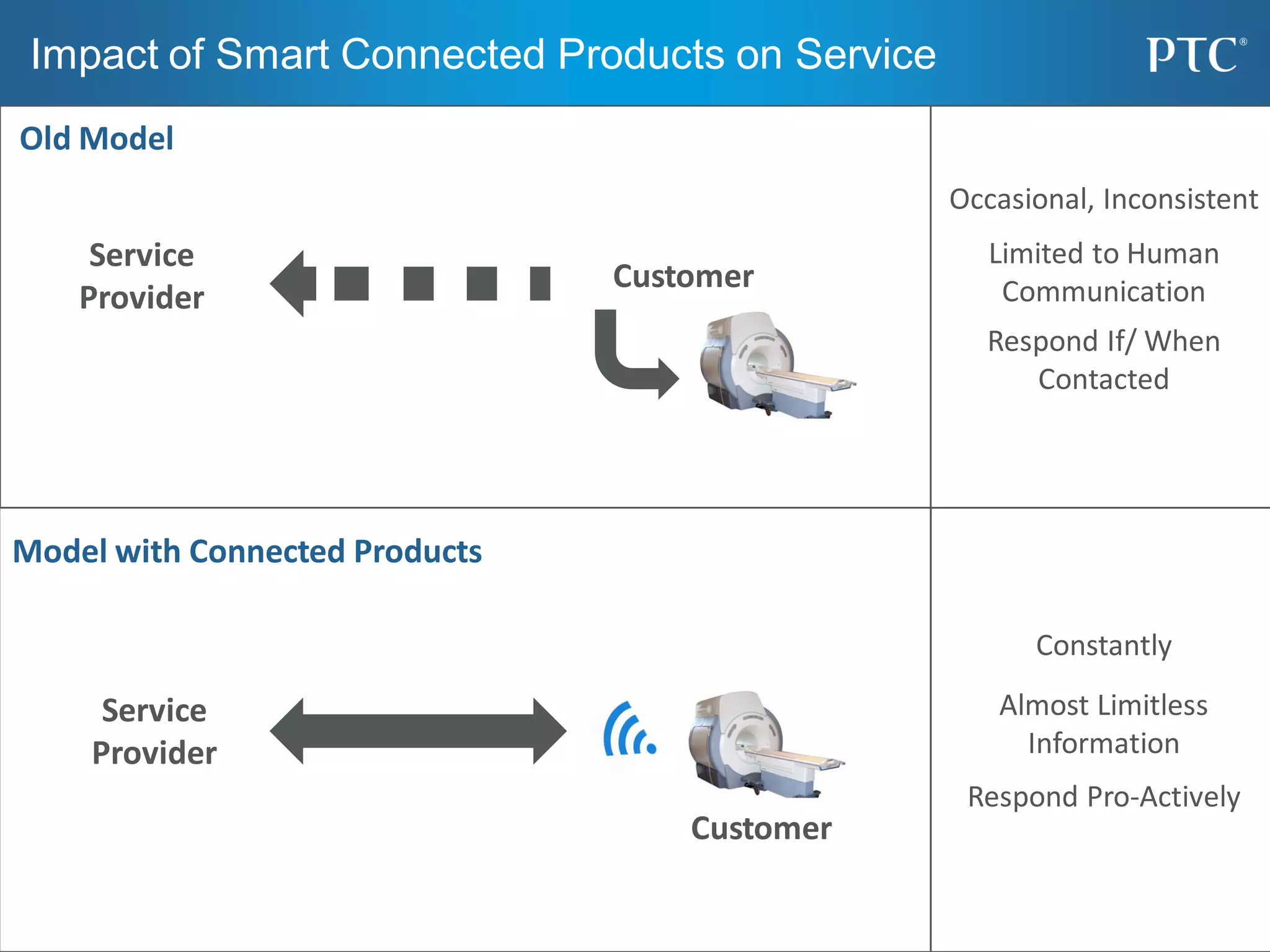

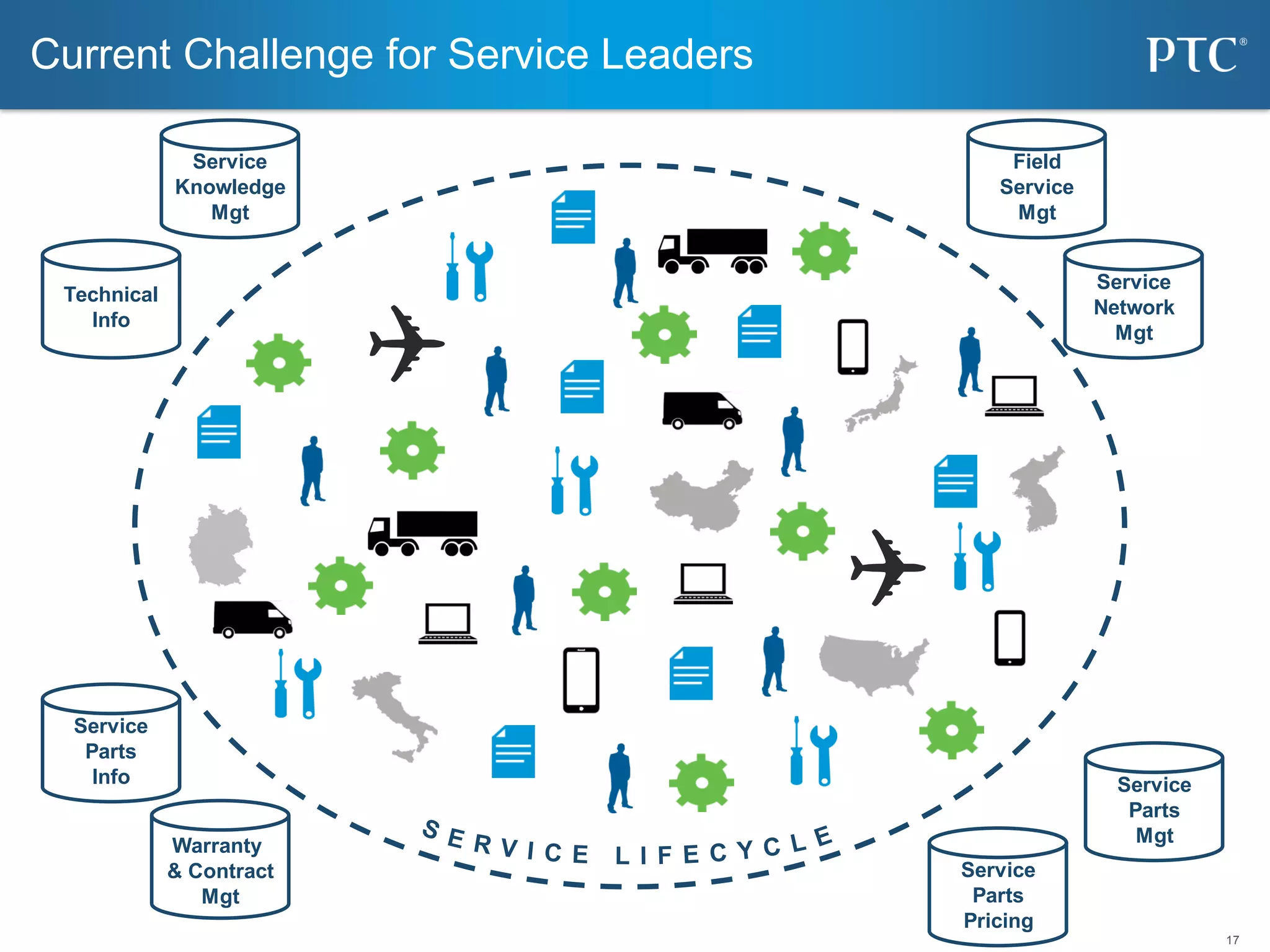

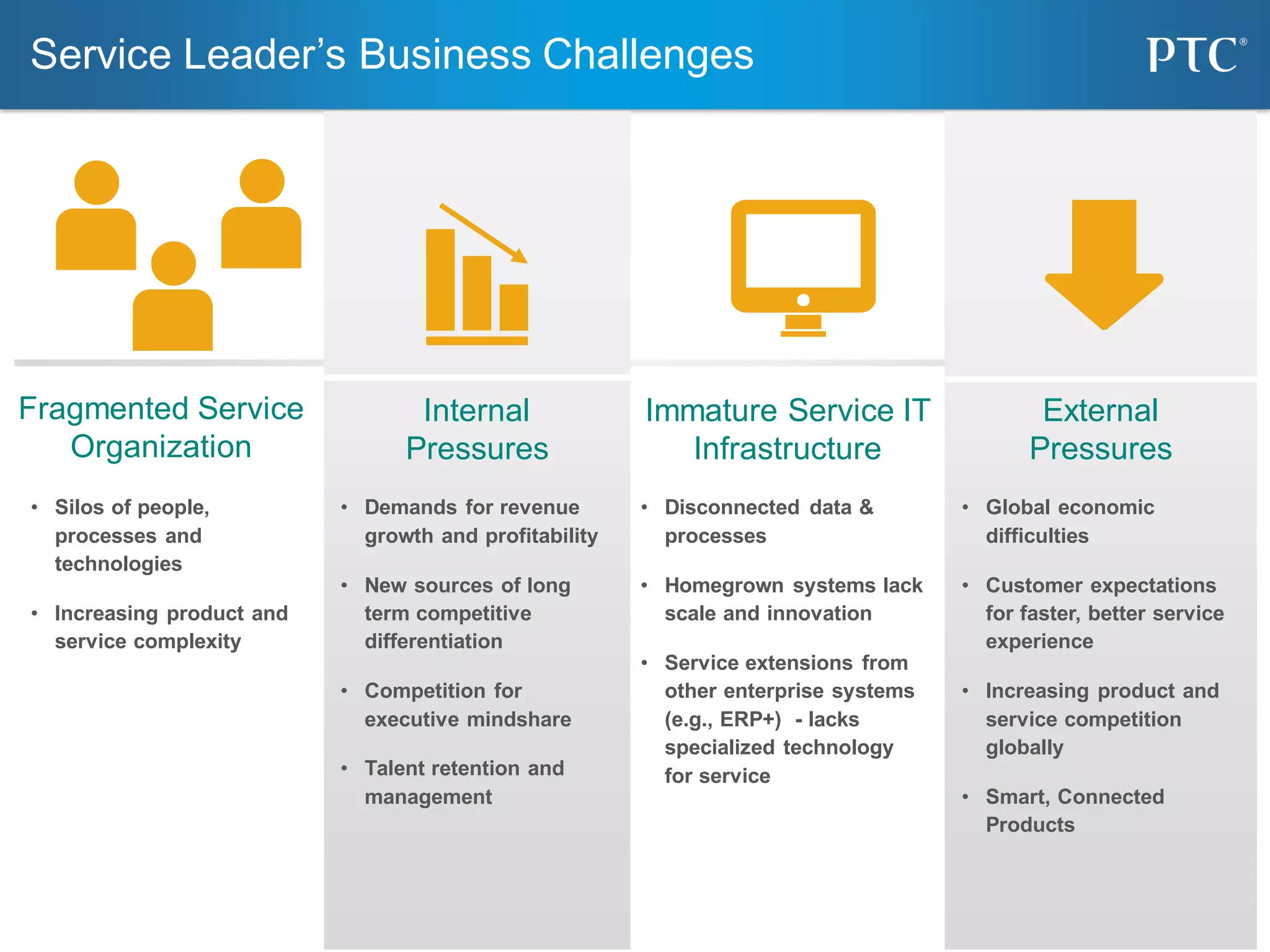

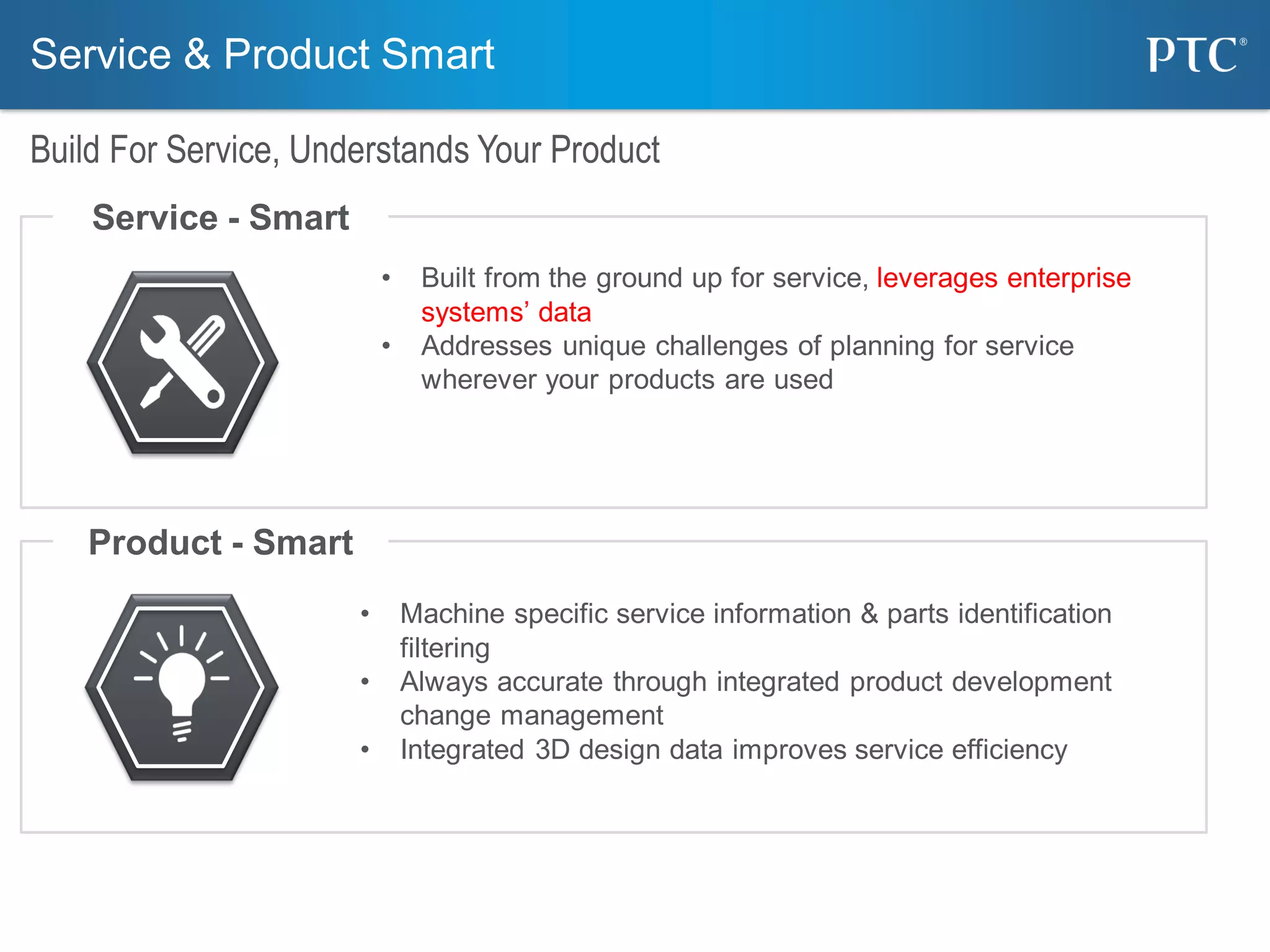

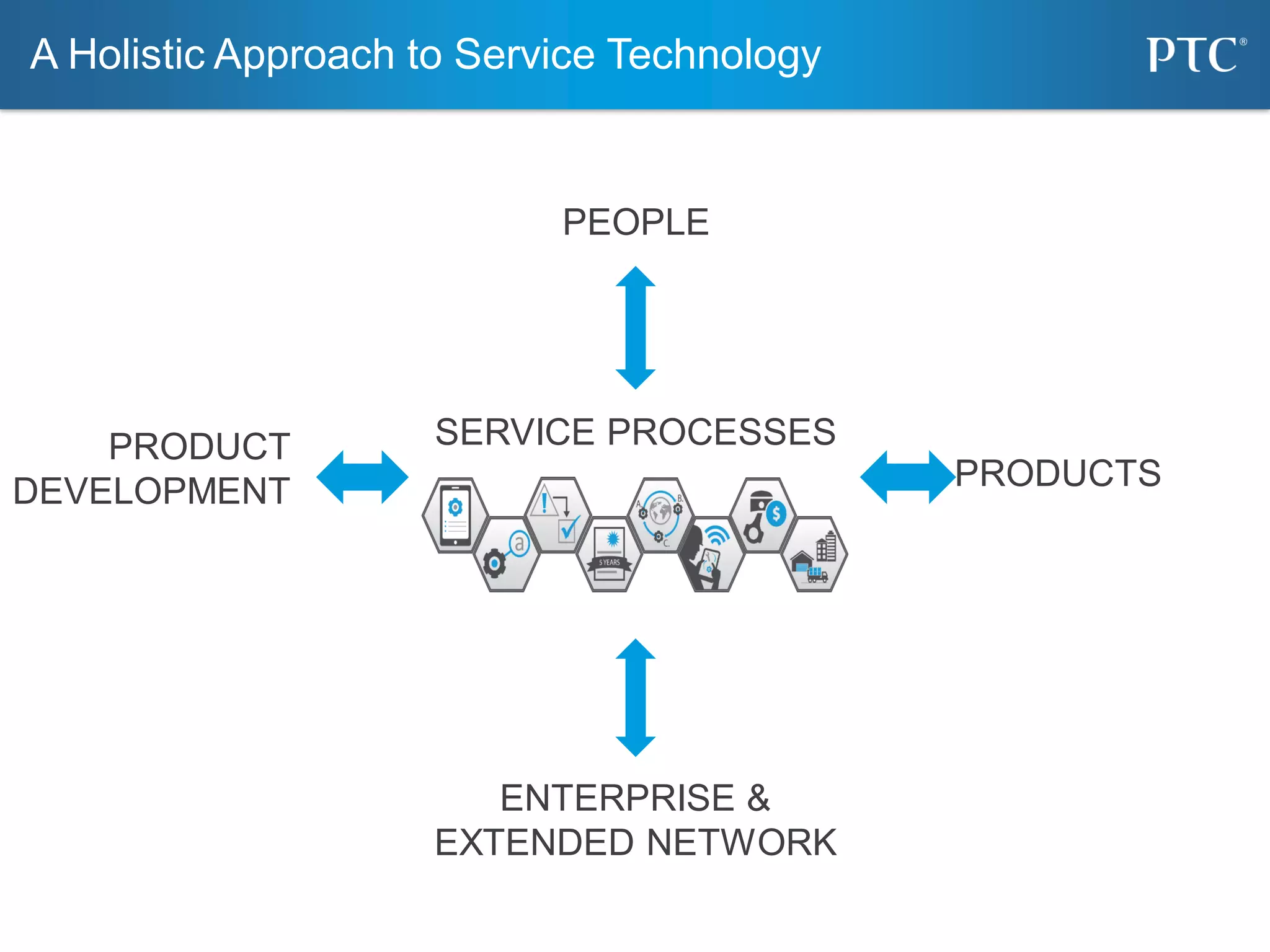

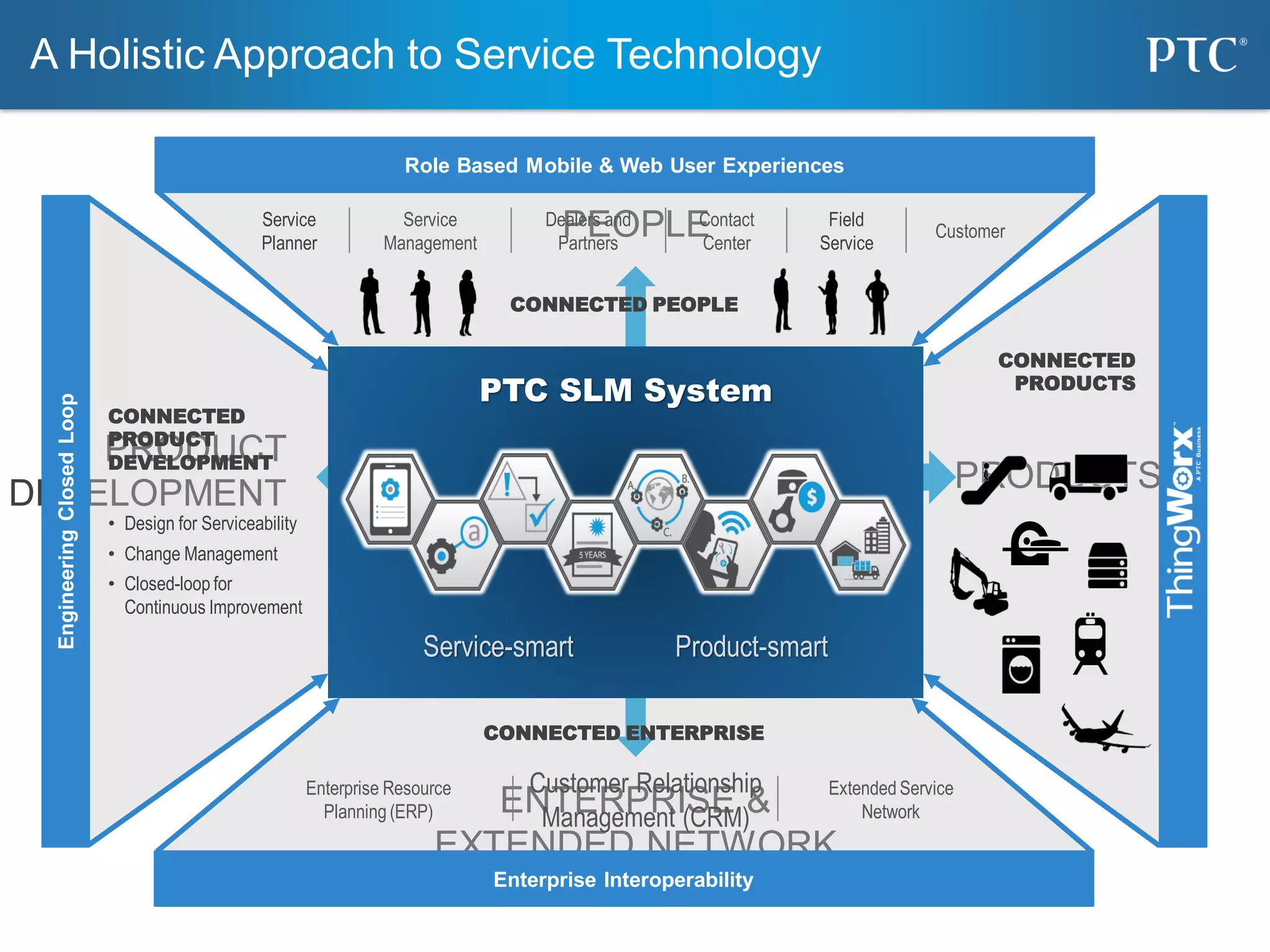

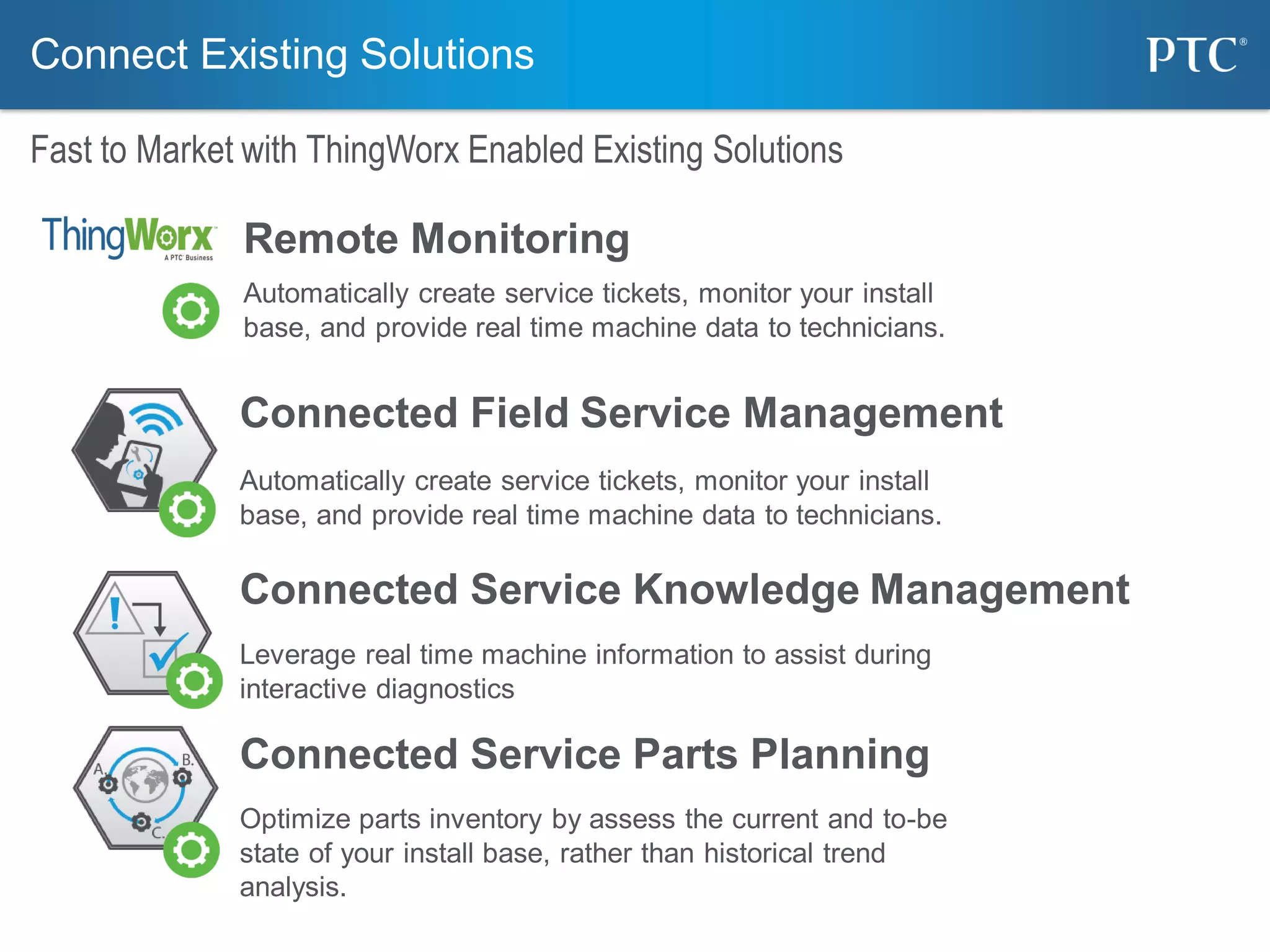

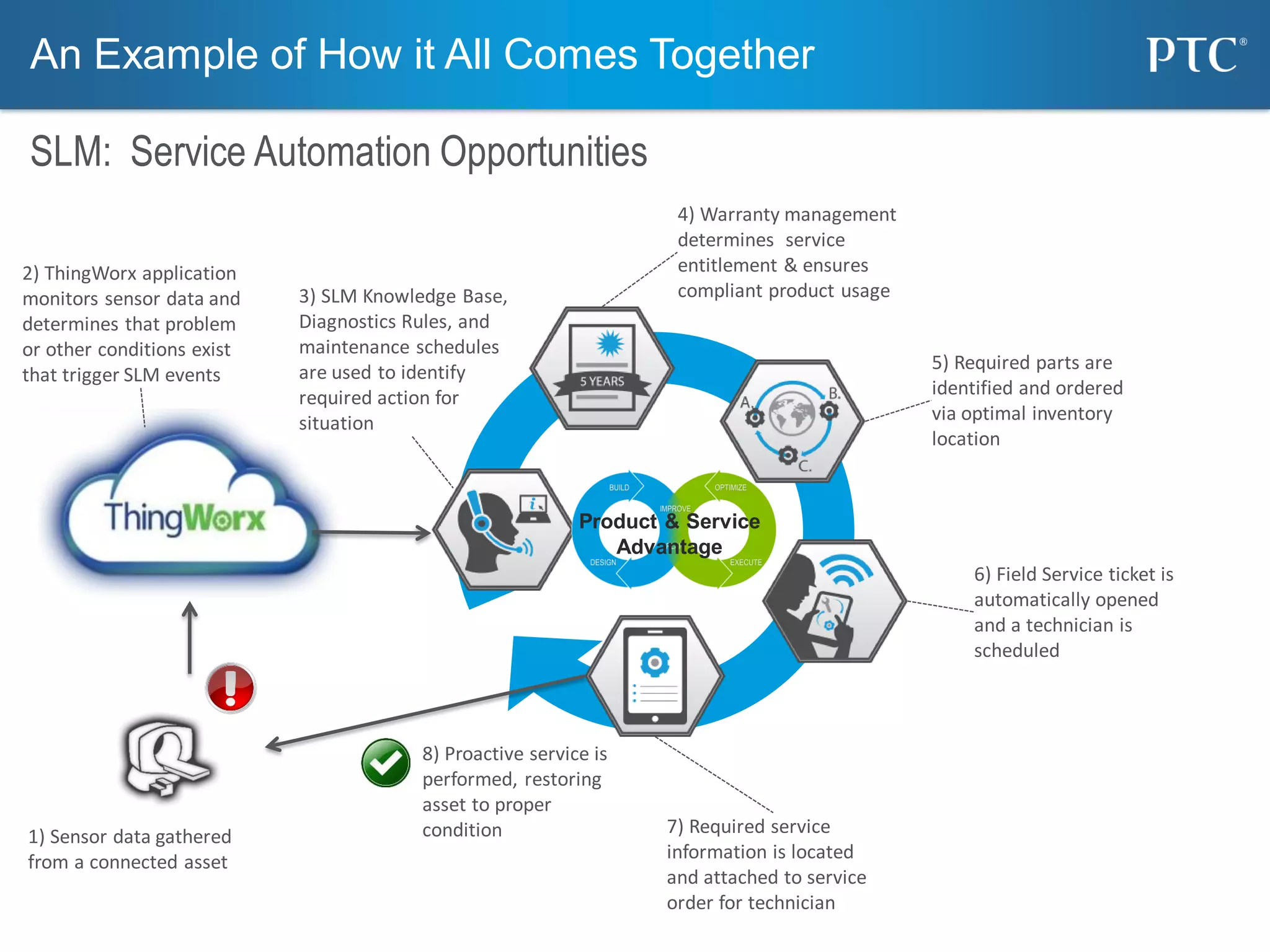

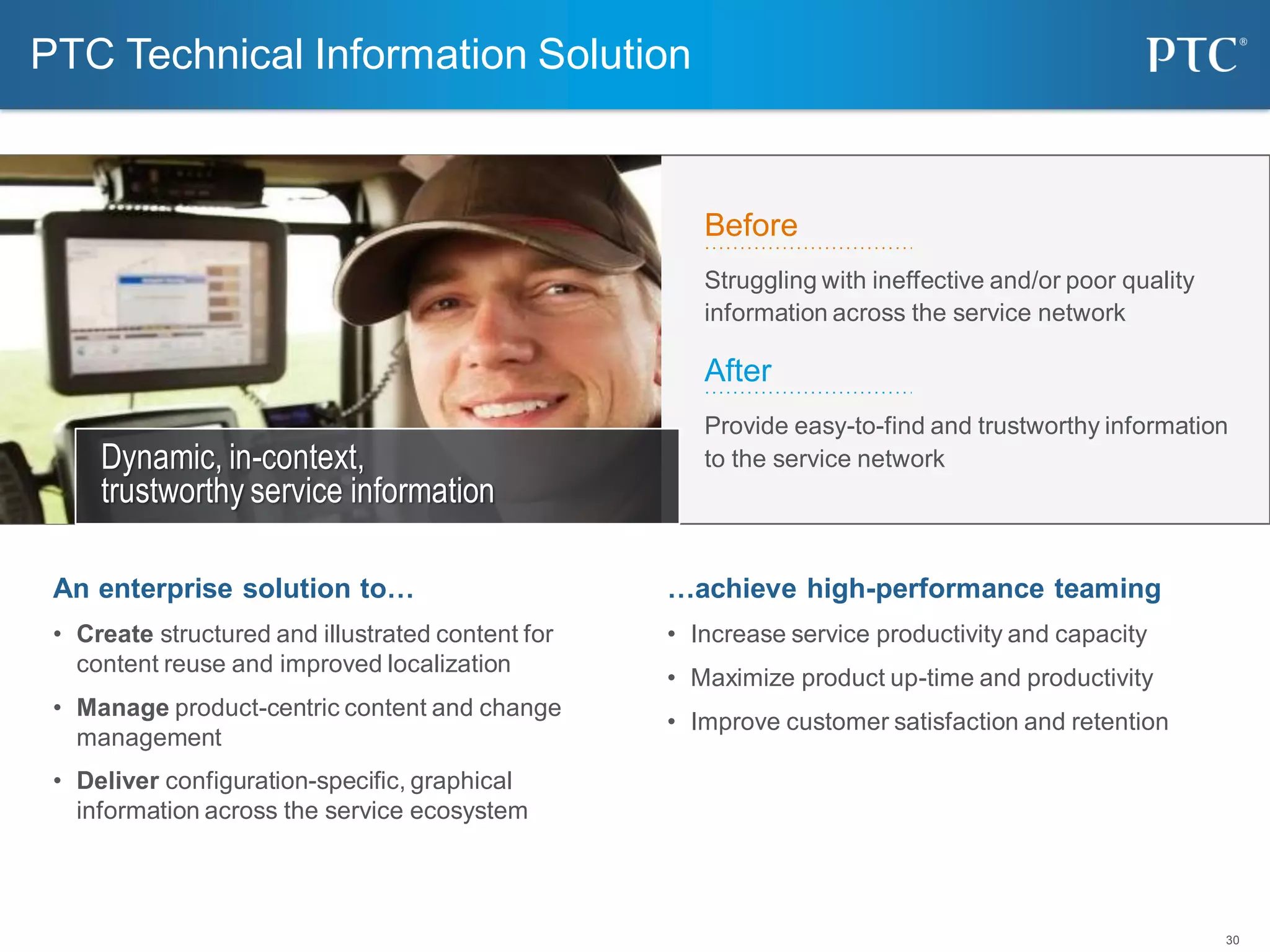

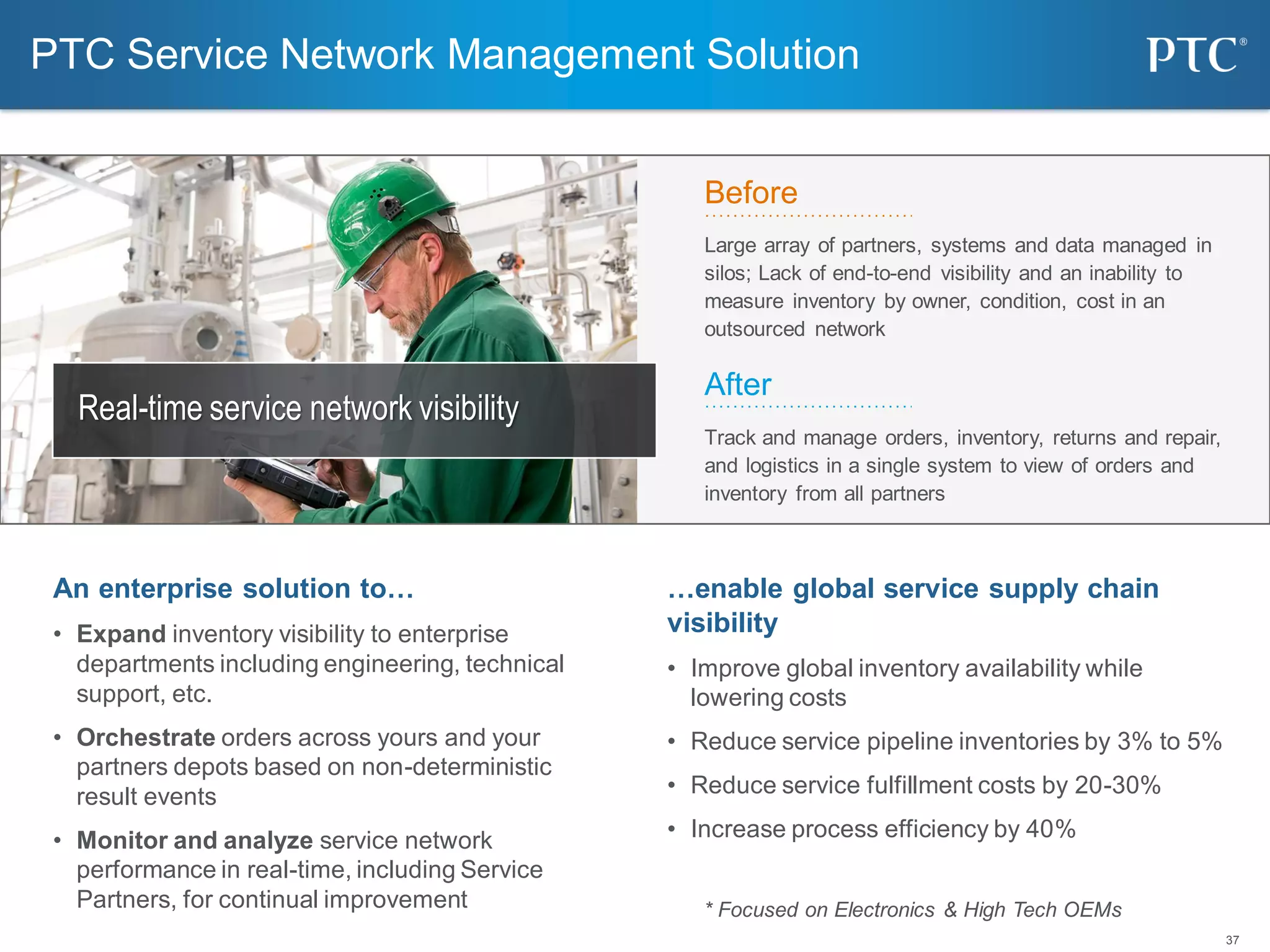

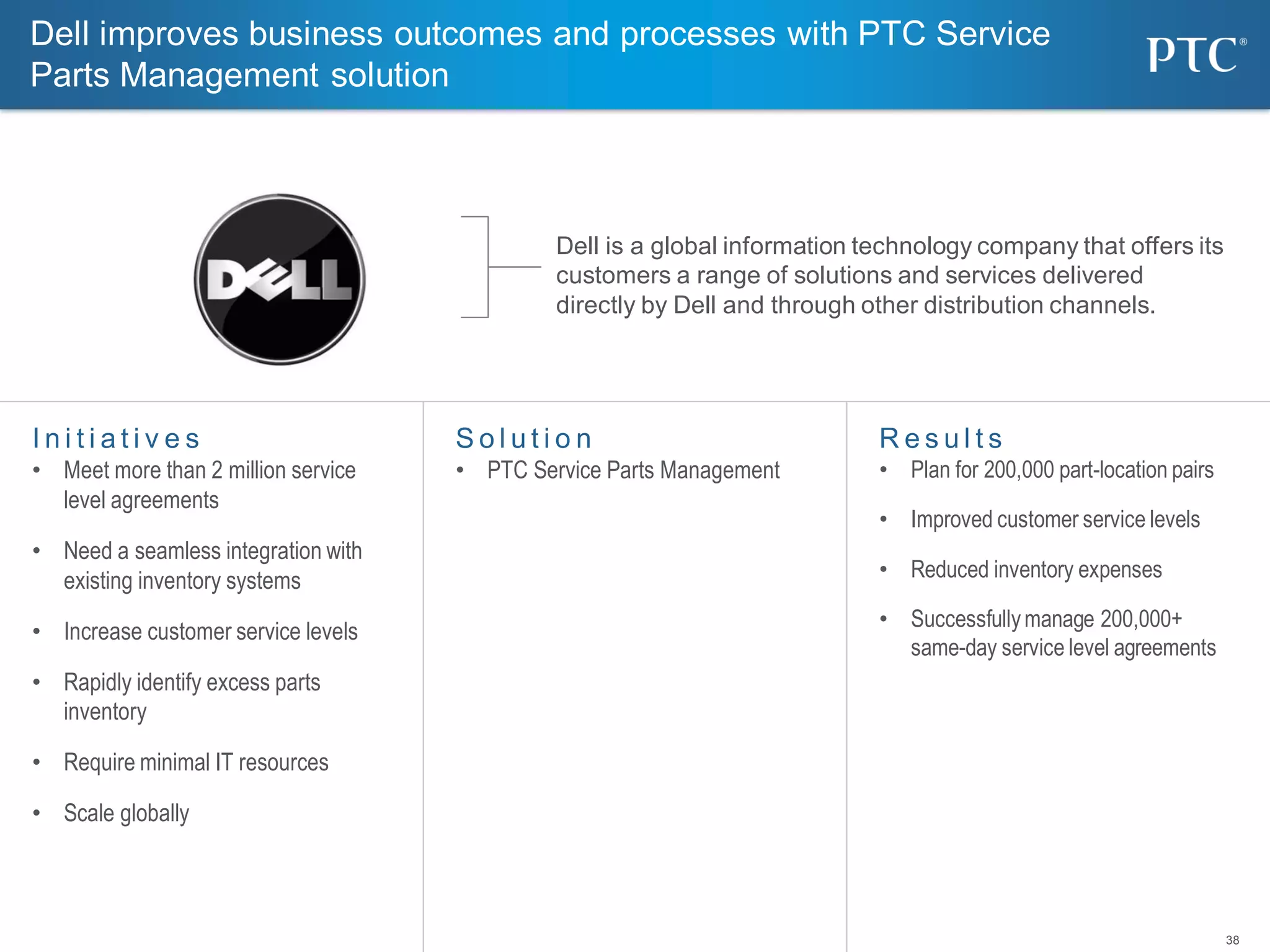

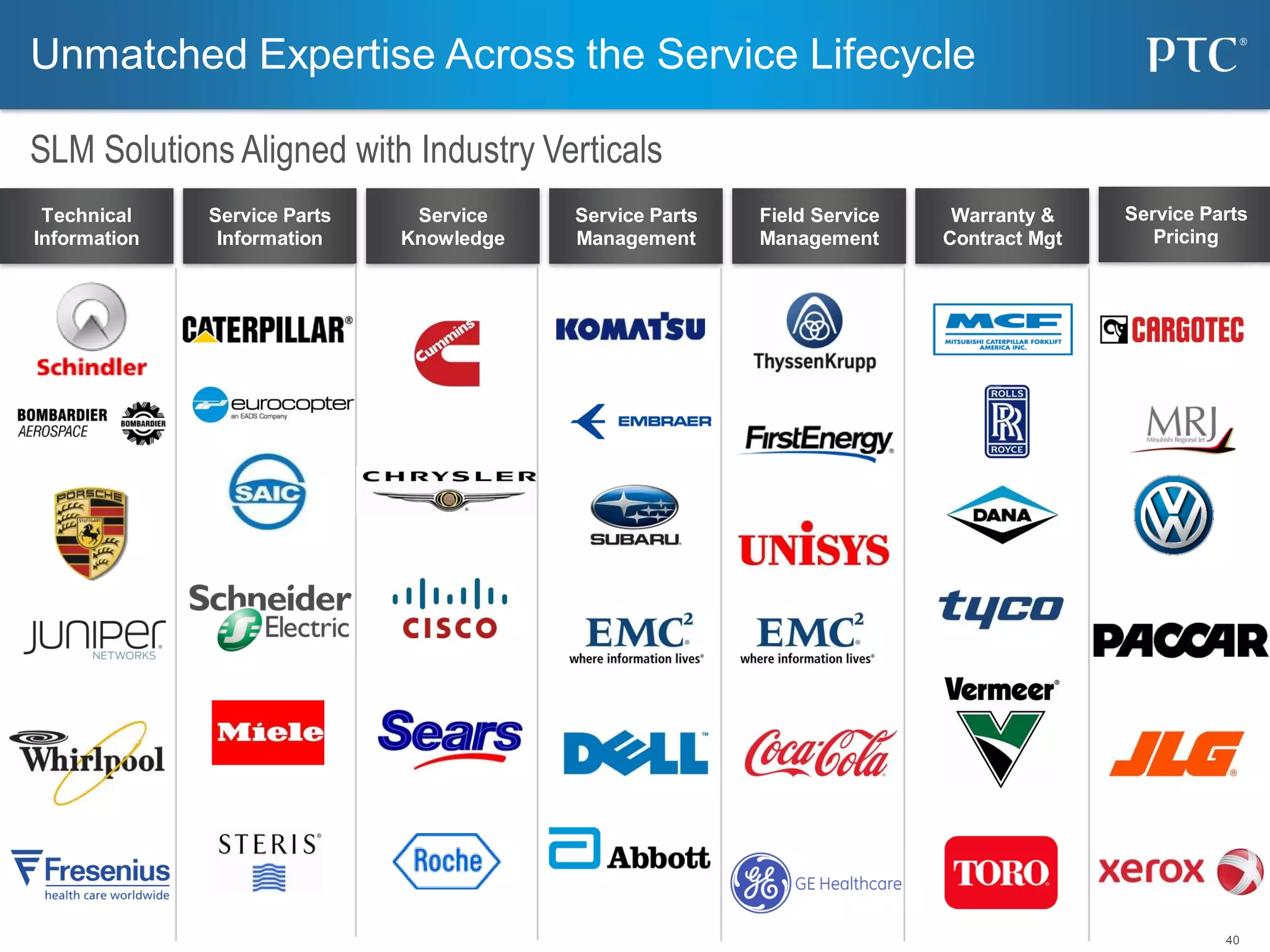

This document provides an overview of PTC's Service Lifecycle Management (SLM) strategy and portfolio. It discusses how PTC SLM solutions can help organizations transform their service business by improving profitability, increasing revenue, and growing customer value. The document outlines challenges currently faced by service leaders and how PTC SLM addresses these challenges through specialized solutions that are product-smart and service-smart. It also provides examples of how specific PTC solutions have helped organizations like Trane and GE Aviation improve their service operations.