Here’s a 50-word summary on **Roofing Products**:

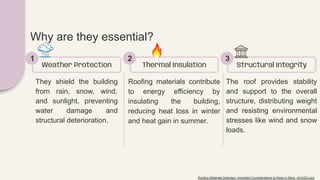

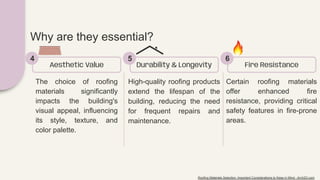

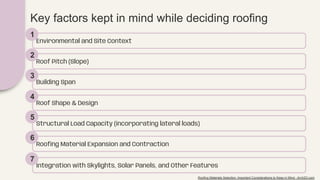

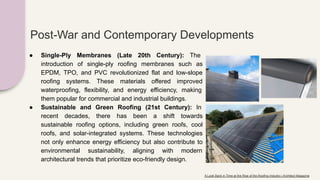

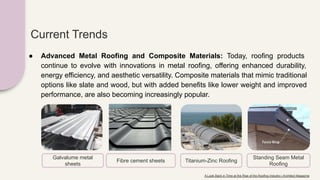

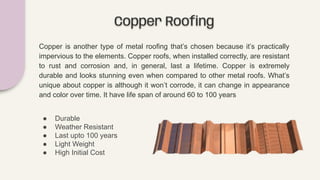

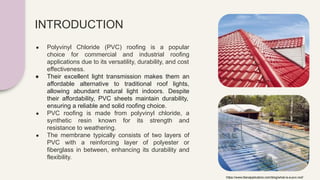

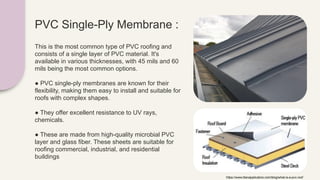

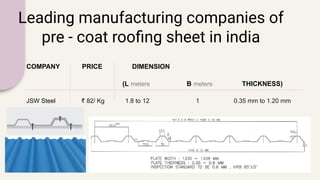

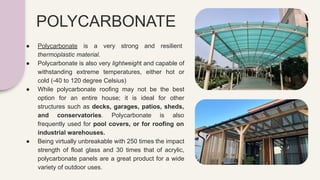

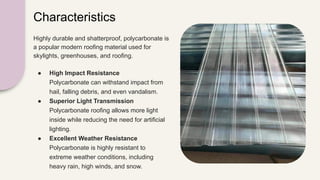

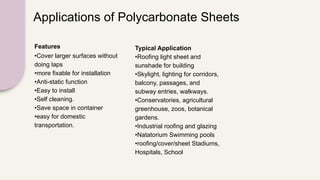

Modern roofing products include metal sheets, clay and concrete tiles, polycarbonate panels, bitumen membranes, and fiber-reinforced plastics. These materials offer durability, thermal insulation, and aesthetic variety. Innovations like lightweight tiles, waterproof coatings, and UV-resistant sheets cater to diverse climates and architectural needs, enhancing both performance and design.

Would you like a comparison table of these materials for your thesis or portfolio?