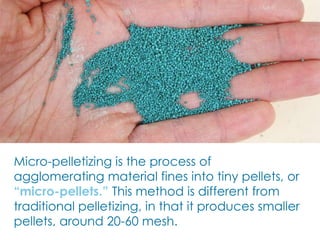

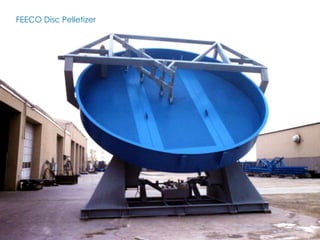

Micro-pelletizing is a process for transforming material fines into small pellets, enhancing material handling, transport, and application across various industries. Benefits include dust reduction, improved safety and product performance, and the ability to process a range of materials like pigments, coal dust, and specialty powders. The technique typically utilizes pin mixers and may involve additional drying processes to optimize the micro-pellet production cycle.