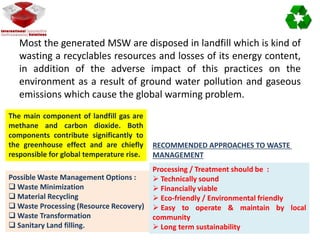

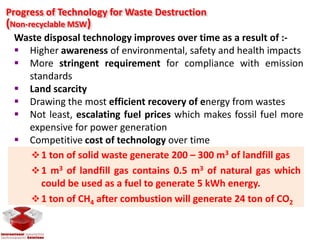

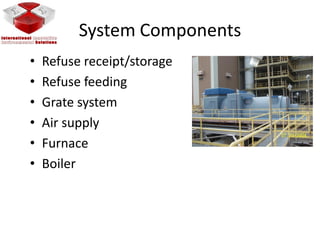

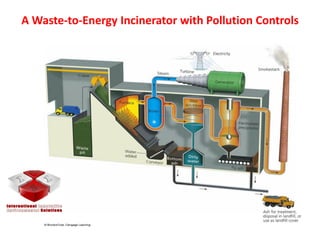

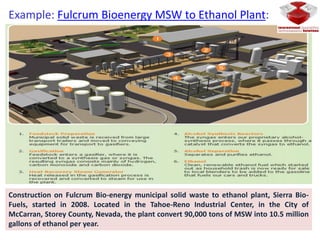

The document discusses integrated green technologies for municipal solid waste (MSW) management. It describes an automated waste collection system and various MSW thermo-chemical conversion technologies, including recycling, combustion, incineration, pyrolysis, gasification, and advanced thermal gasification. Incineration can generate energy from MSW but requires effective pollution controls. Emerging technologies like gasification and pyrolysis produce syngas and oils while advanced thermal gasification vitrifies waste into inert materials. Overall, thermal conversion technologies allow for more sustainable MSW management compared to landfilling but require further commercialization and environmental assessment.