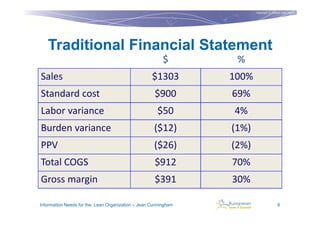

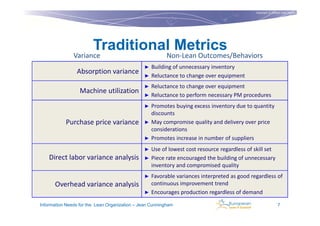

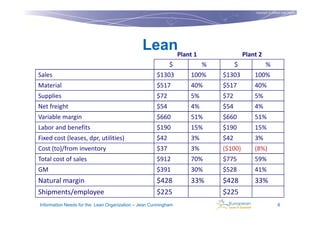

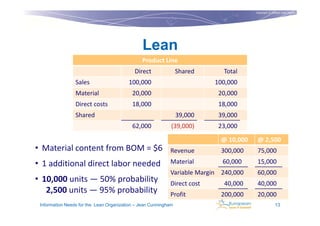

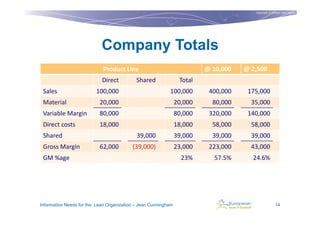

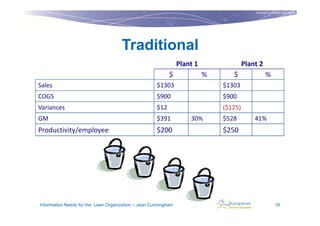

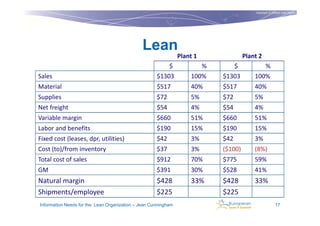

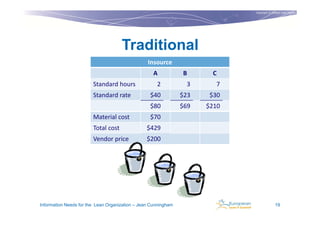

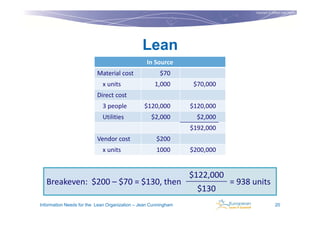

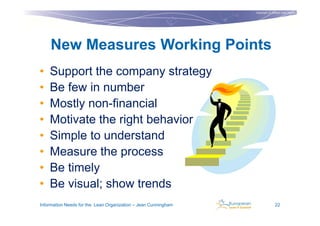

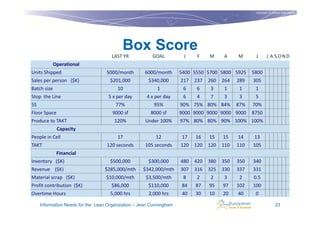

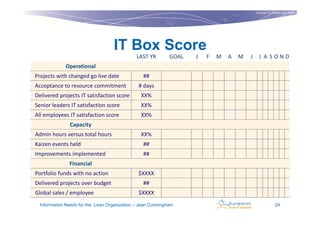

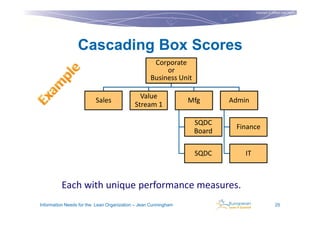

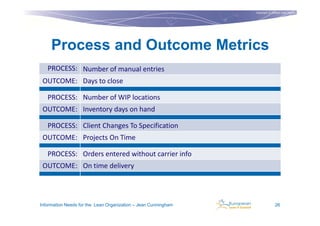

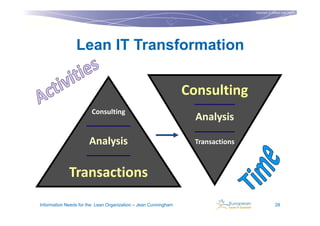

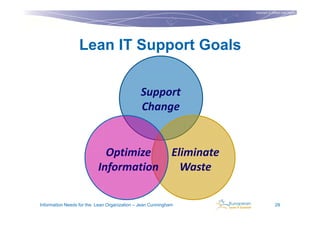

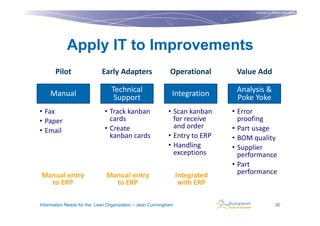

The document discusses the importance of lean accounting for organizations transitioning to lean practices, highlighting issues with traditional standard cost accounting that impede lean outcomes. It emphasizes the need for new performance measures that align with lean principles, supporting continuous improvement and operational efficiency. Additionally, it outlines various metrics and a transformative roadmap to lean methodologies in financial and operational contexts.