Embed presentation

Download as PDF, PPTX

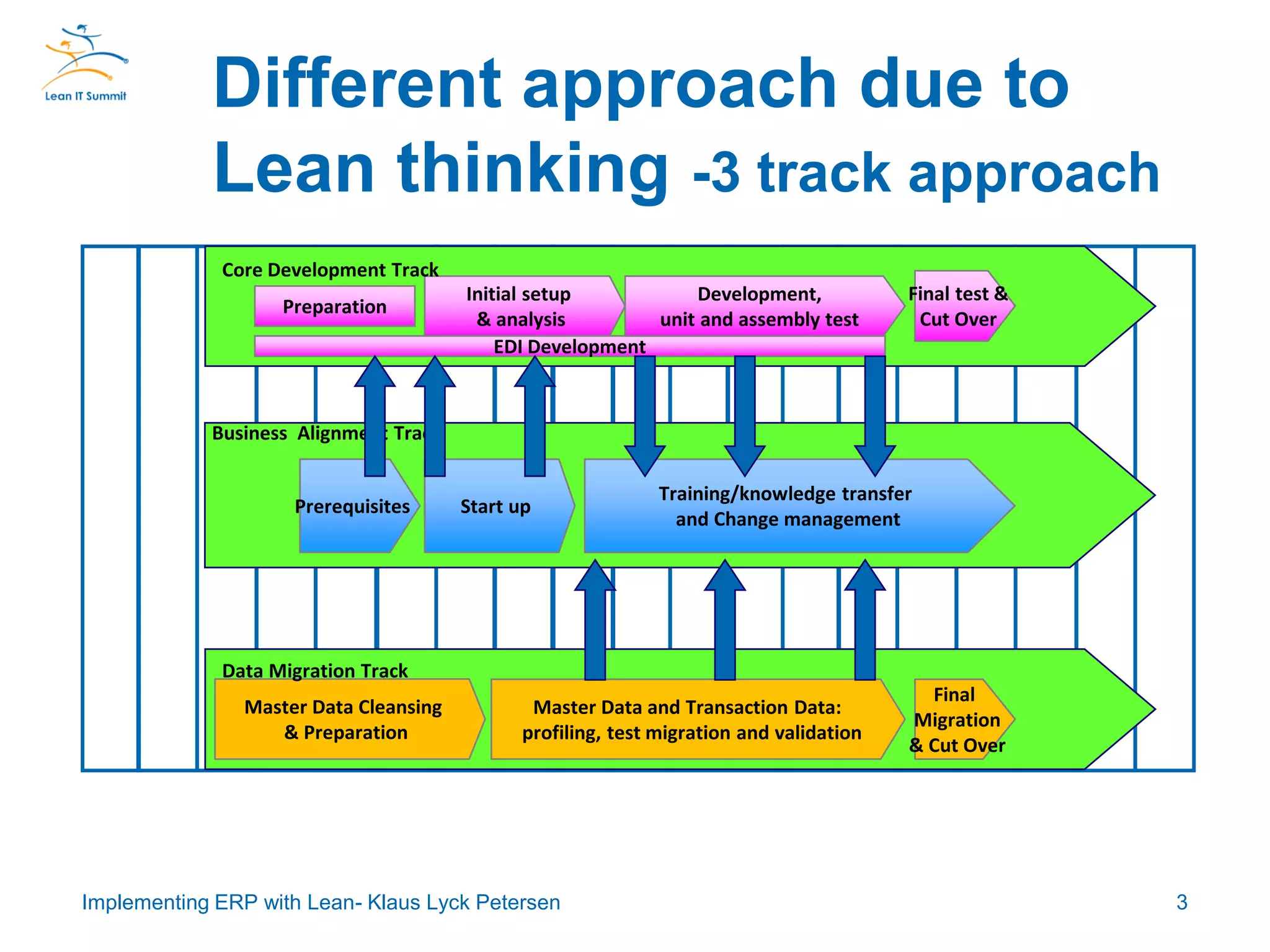

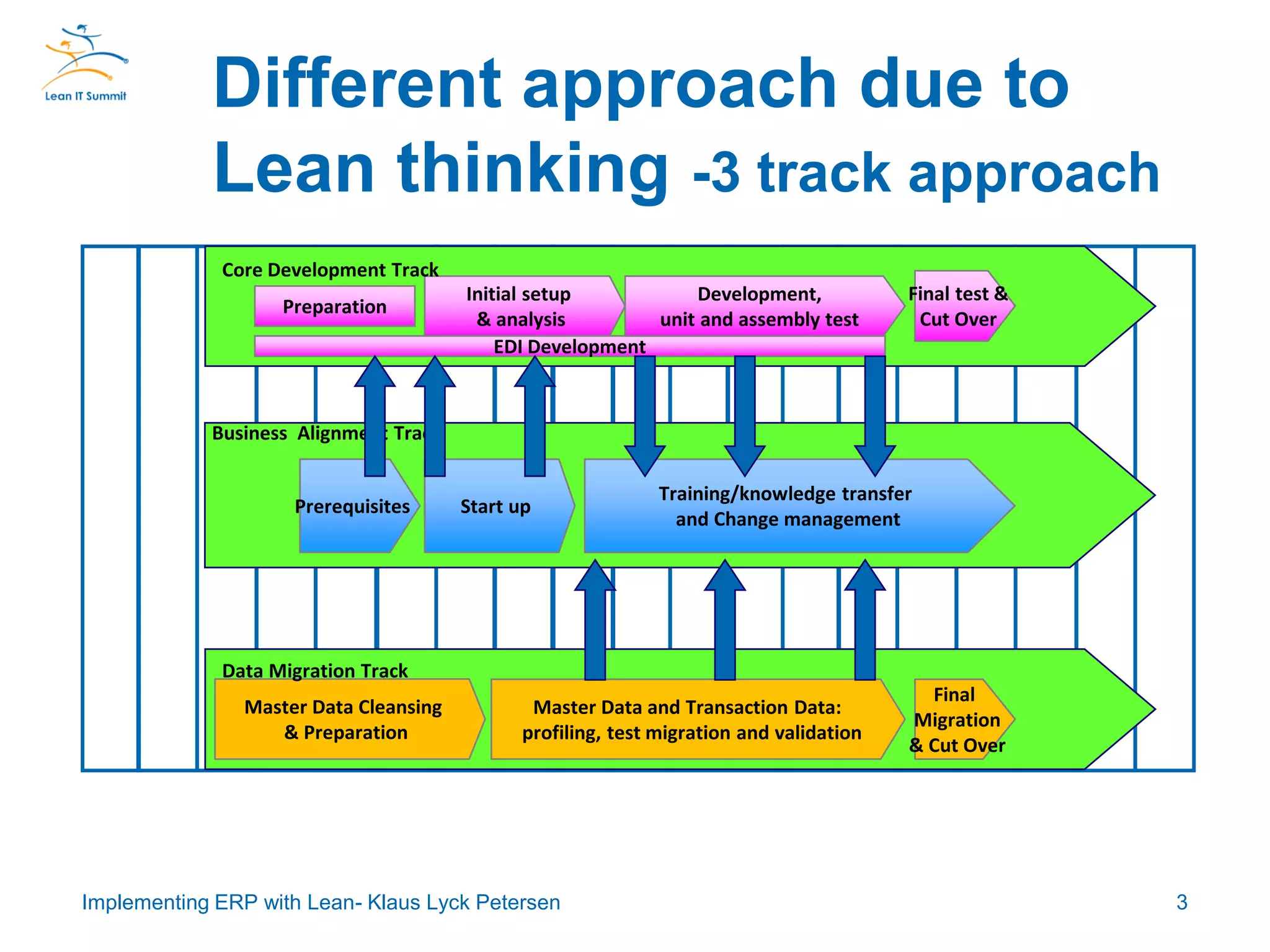

The document outlines a Lean IT Summit presentation by Klaus Lyck Petersen regarding transforming a failed ERP implementation into a successful one using Lean methodologies. It discusses the importance of leadership, clear roles, business alignment, and effective communication for a smooth transition and highlights benefits such as attracting new customers and improving lead times. Key learnings from the process emphasized the necessity of using assessment tools and aligning priorities during the implementation phases.