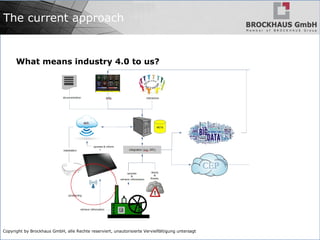

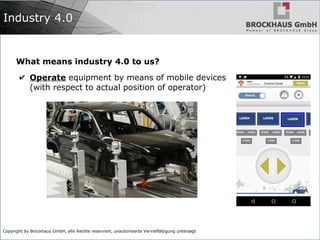

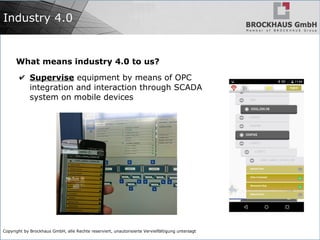

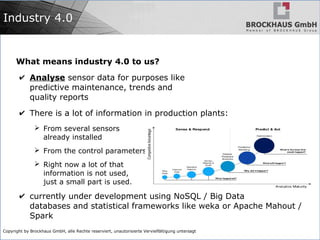

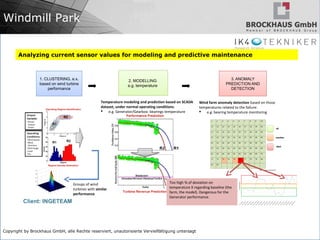

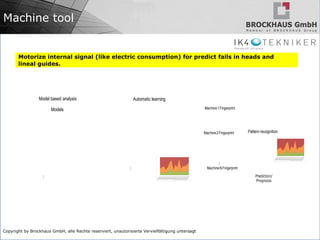

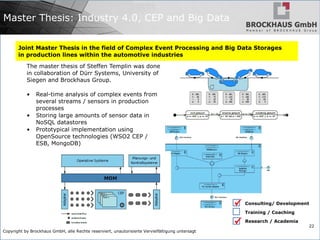

This document discusses Industry 4.0 and what it means for the partnership between Tekniker/ES and Brockhaus Group. It defines Industry 4.0 as the fourth industrial revolution focused on software and information processing. It describes how Industry 4.0 will enable decentralized production through smart objects, autonomous products, and real-time decision making. For the partnership, Industry 4.0 means opportunities to improve production quality through data analysis, optimize maintenance through equipment prognostics, and enable new ways of interacting with equipment via mobile devices and augmented reality. Example reference projects are described that apply predictive maintenance, anomaly detection, and big data analysis to wind turbines, machine tools, and automotive production lines.