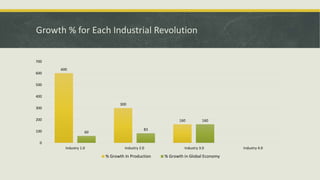

The document is a seminar presentation on Industry 4.0 (also known as the fourth industrial revolution). It discusses the history and progression of industrial revolutions from Industry 1.0 to 4.0. Industry 4.0 is characterized by the integration of cyber-physical systems, the Internet of Things, big data analytics, and artificial intelligence. The presentation covers literature on Industry 4.0, the methodology used, recent trends like 5G networks and digital twins, applications in smart factories and supply chain optimization, advantages like improved efficiency and sustainability, and disadvantages such as high costs and security risks. It concludes that Industry 4.0 will reshape the global economy through increased productivity and customization while also presenting challenges that must be addressed strateg

![Bibliography

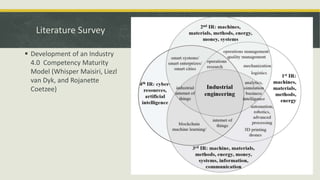

[1] Based on “Development of an Industry 4.0 Competency Maturity Model” by Whisper Maisiri and Liezl van

Dyk which appeared in the Proceedings of 2020 IFEES World Engineering Education Forum - Global Engineering

Deans Council (WEEF-GEDC), virtual conference, 16 - 19 November 2020. © 2020 IEEE

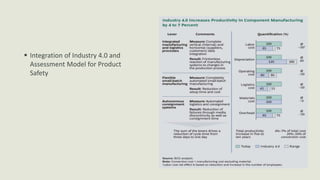

[2] C. H. Li1 and H. K. Lau2 “Integration of Industry 4.0 and Assessment Model for Product Safety “ By School of

Science and Technology, The Open University of Hong Kong, Hong Kong, China

[3] Petr Novak´∗, Petr Douda∗, Petr Kadera∗, Jiˇr´ı Vyskocil ˇ∗

∗ Czech Institute of Informatics, Robotics and Cybernetics, Czech Technical University in Prague,

Prague, Czech Republic. “PyMES: Distributed Manufacturing Execution System for Flexible Industry 4.0 Cyber-

PhysicalProduction Systems”

[4] Sibukele Gumboa,*, Hossana Twinomurinzia, Kelvin Bwalyaa, Samuel Fosso Wambab “Skills provisioning for

the Fourth Industrial Revolution: A Bibliometric Analysis”

[5] M P Metri, Executive Committee Member, IEILC, Belagavi “INDUSTRY 4.0 TECHNOLOGIES”](https://image.slidesharecdn.com/industry4-1-240222122352-d0284941/85/INDUSTRY-4-0-which-covers-IOT-AI-Augmented-reality-18-320.jpg)