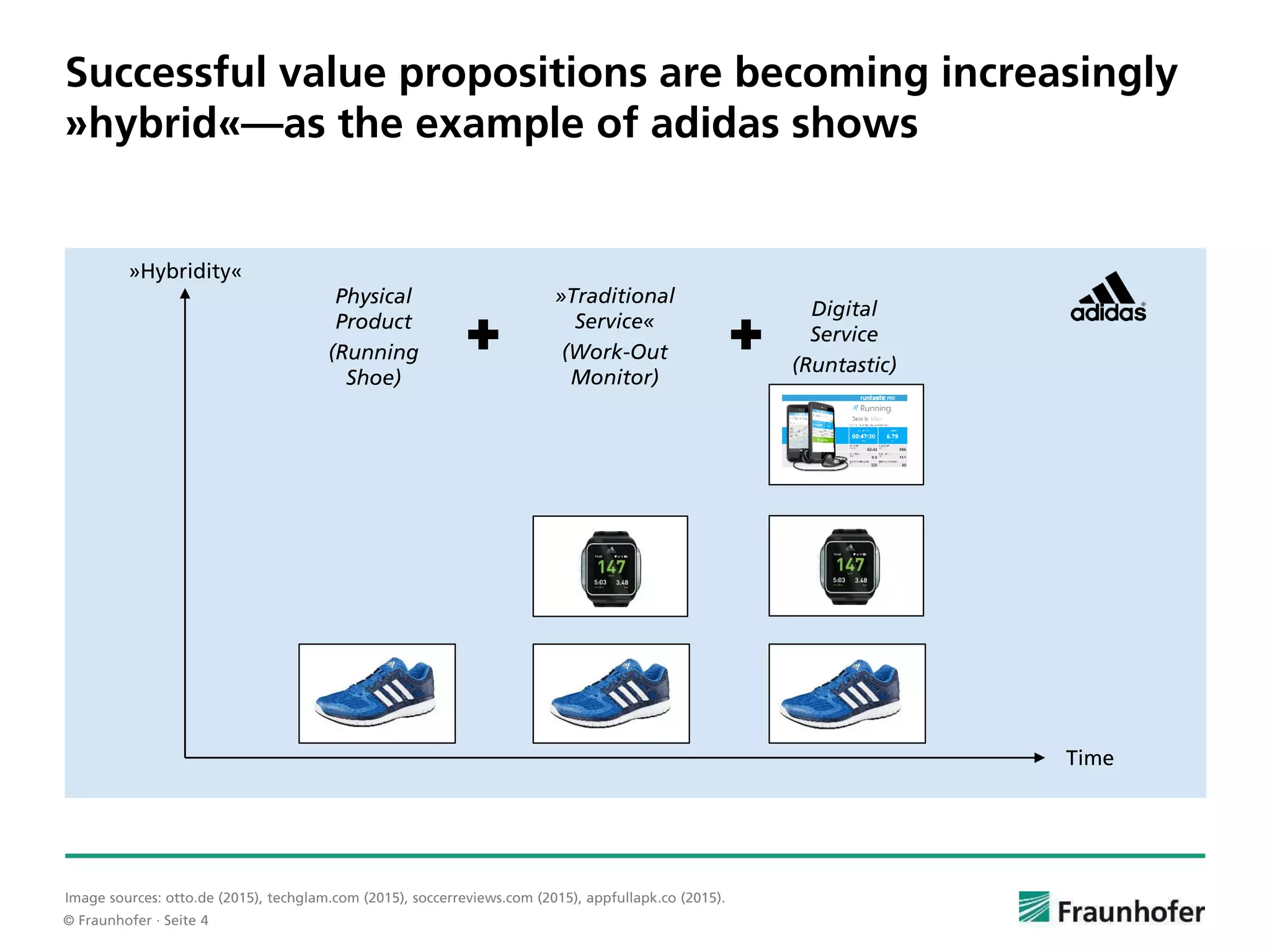

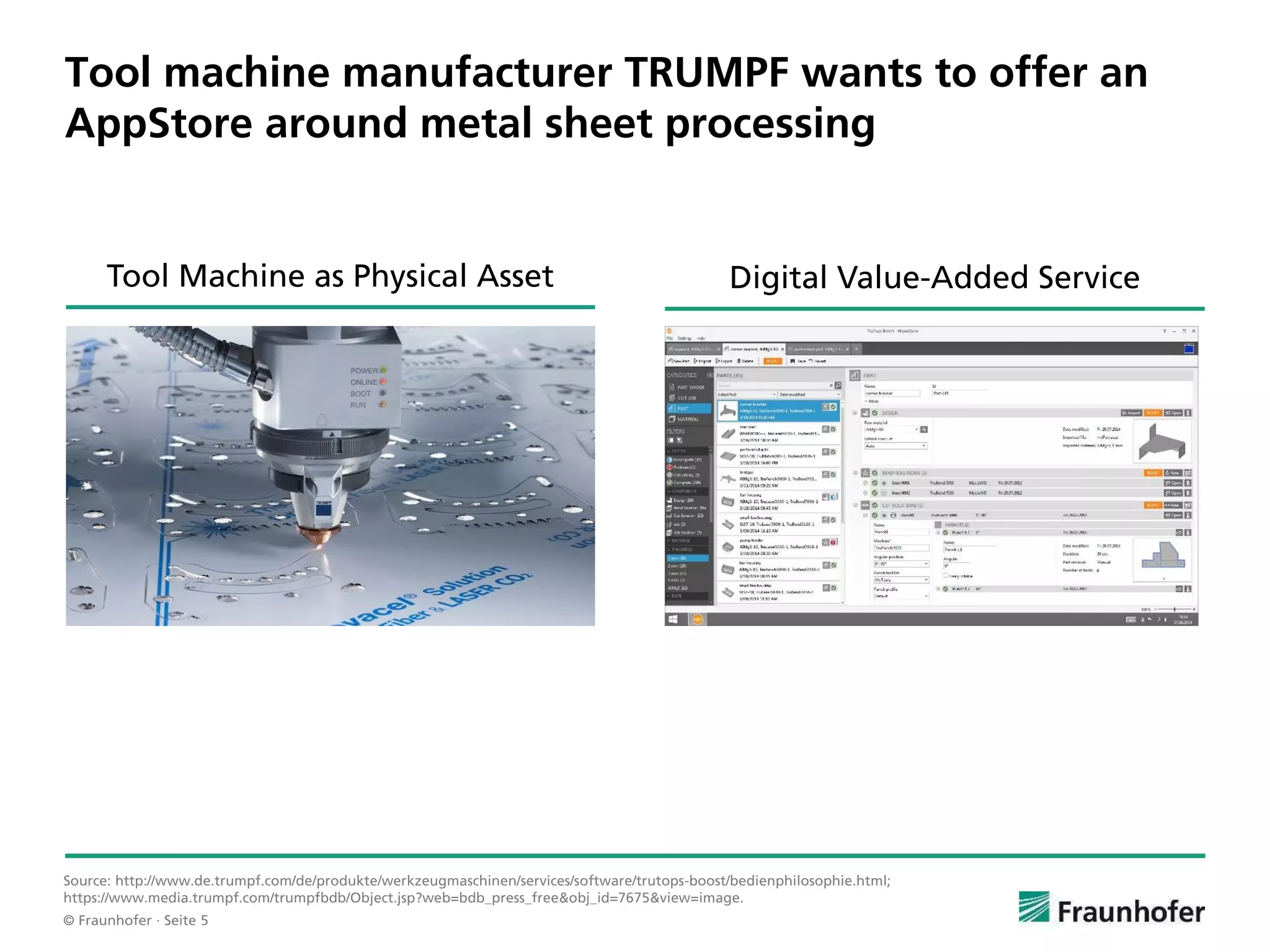

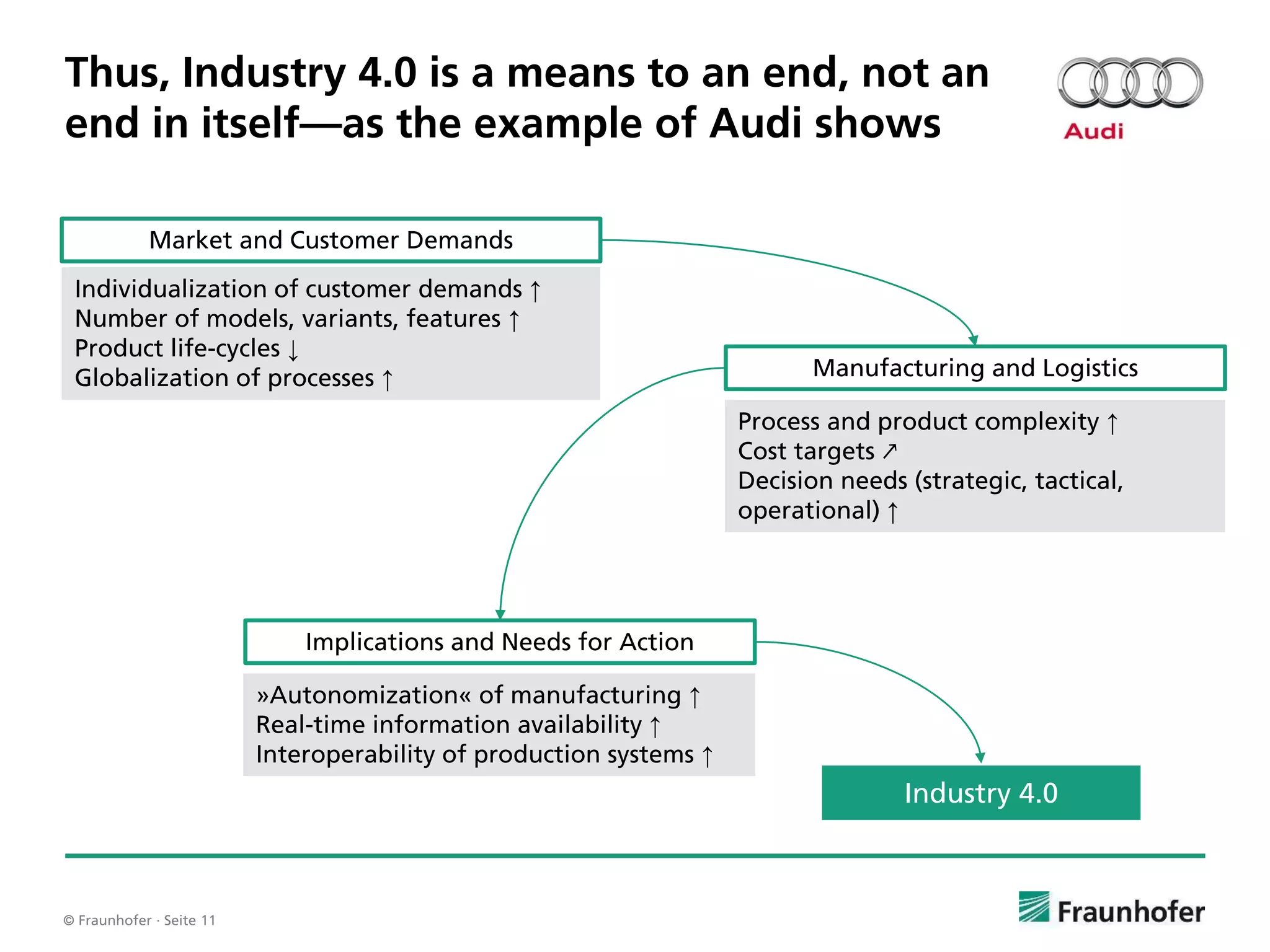

The document discusses the concept of Industry 4.0, emphasizing its role in enabling smart manufacturing through cyber-physical systems and decentralized control. It highlights the importance of data as a strategic resource to link smart services and manufacturing, as well as the creation of an industrial data space that aims for a network of trusted data and services. Examples from various industries illustrate the shift towards individualized production and the hybridization of products and services.