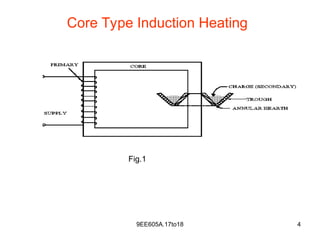

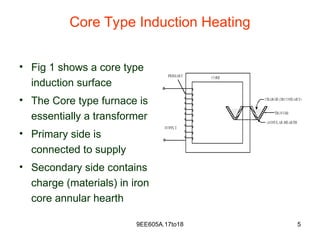

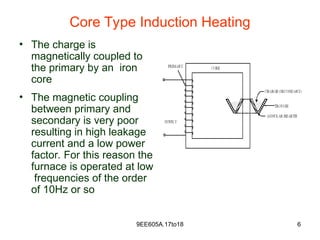

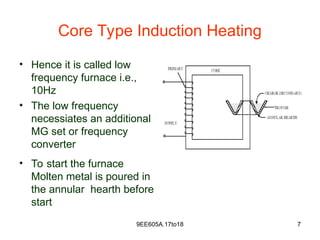

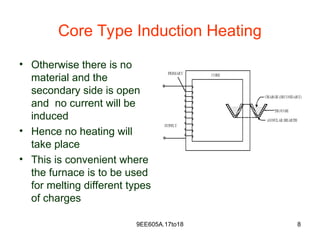

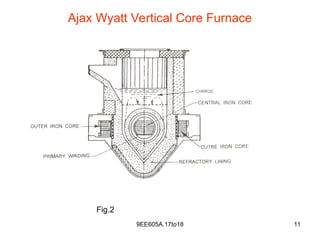

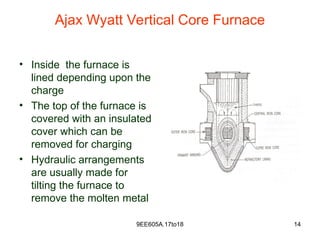

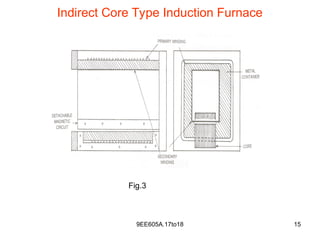

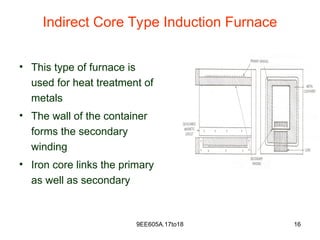

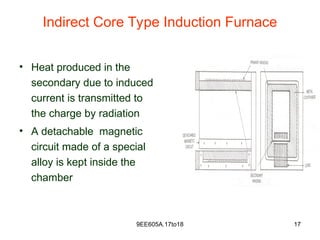

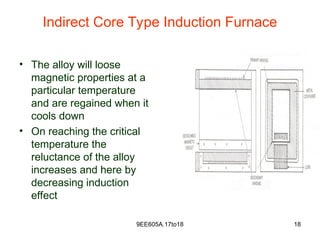

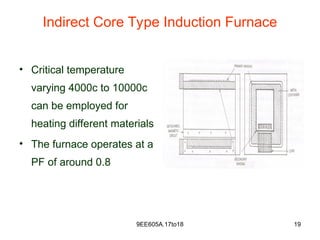

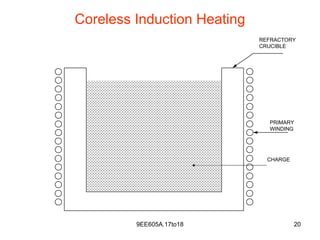

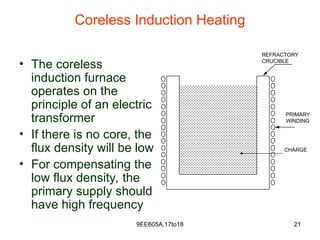

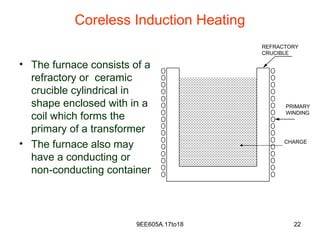

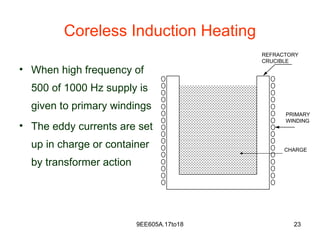

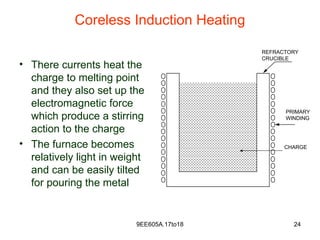

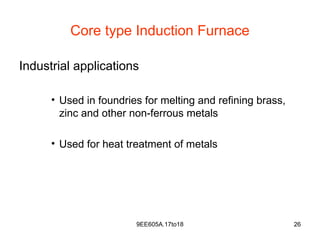

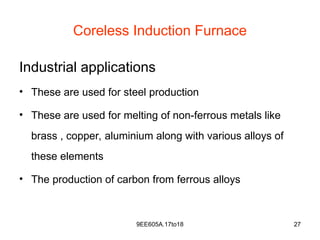

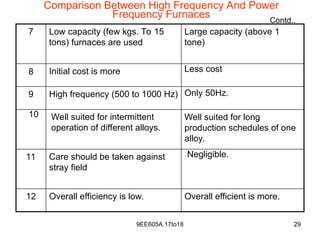

The document discusses induction heating, explaining its process and applications, including core type and coreless induction furnaces. Induction heating is based on electromagnetic action to generate heat in conductive materials, while coreless induction furnaces offer advantages such as higher heating speeds and lower operational costs. Various industrial applications and comparisons between high frequency and power frequency furnaces are also covered.