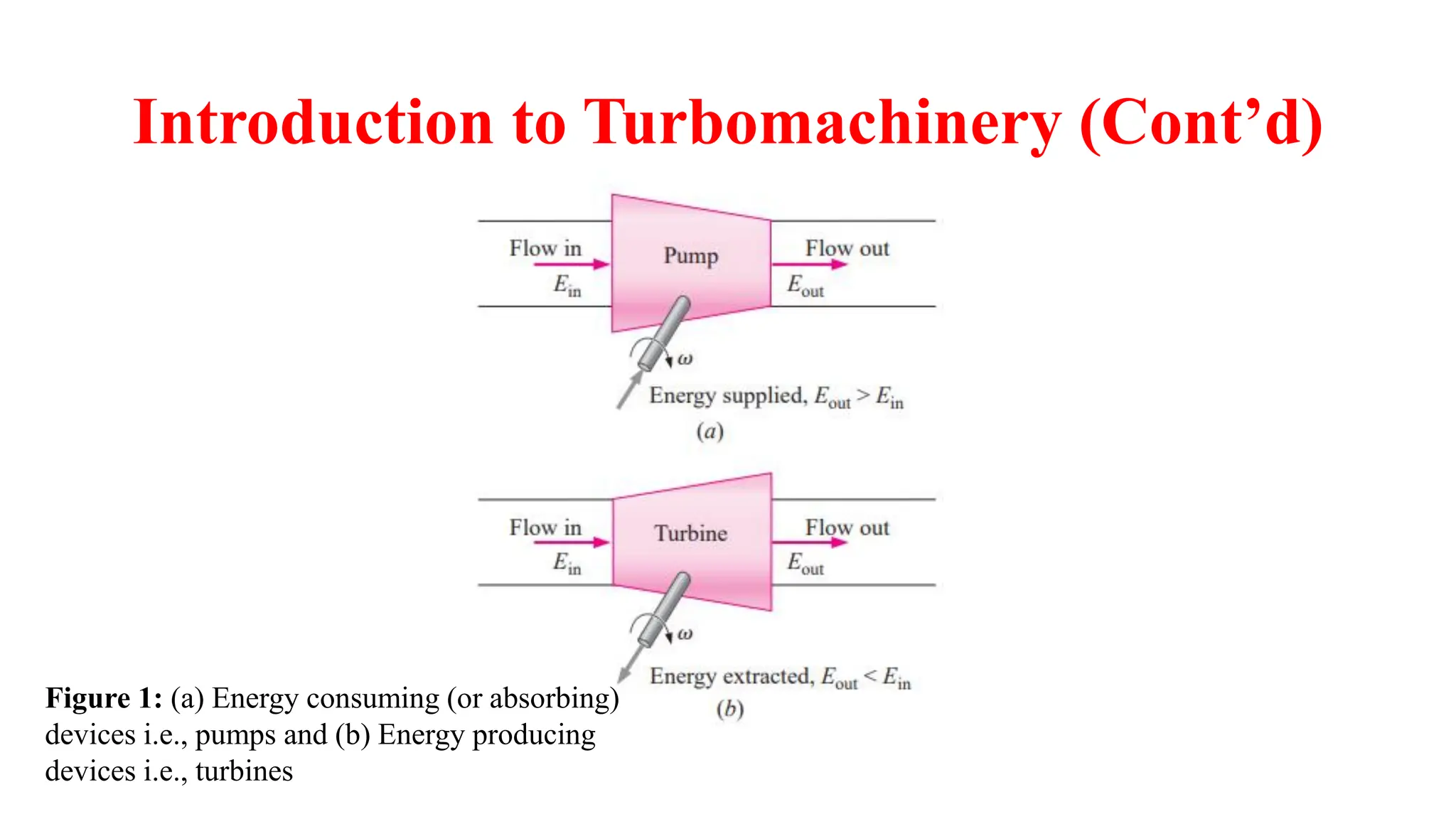

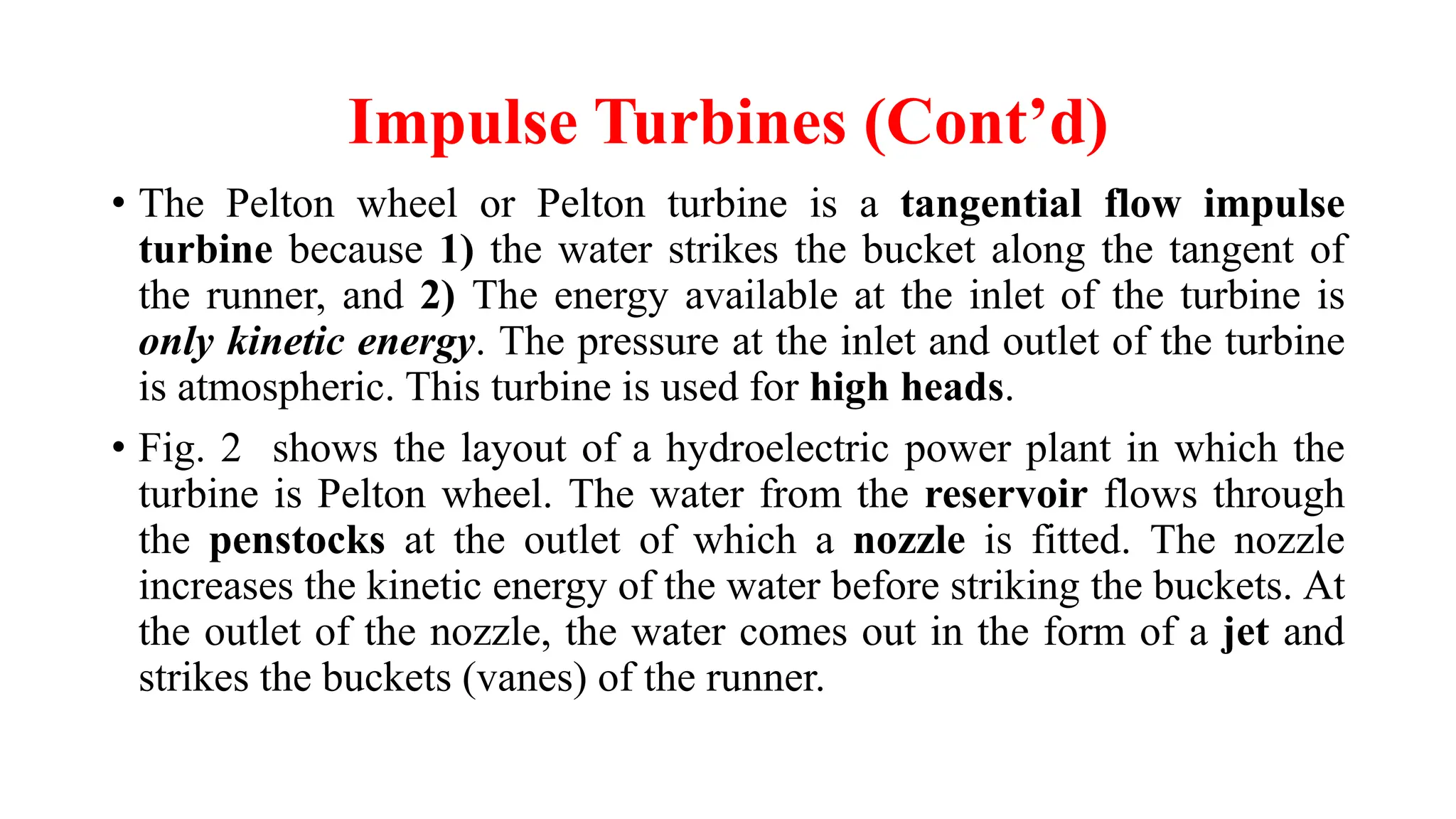

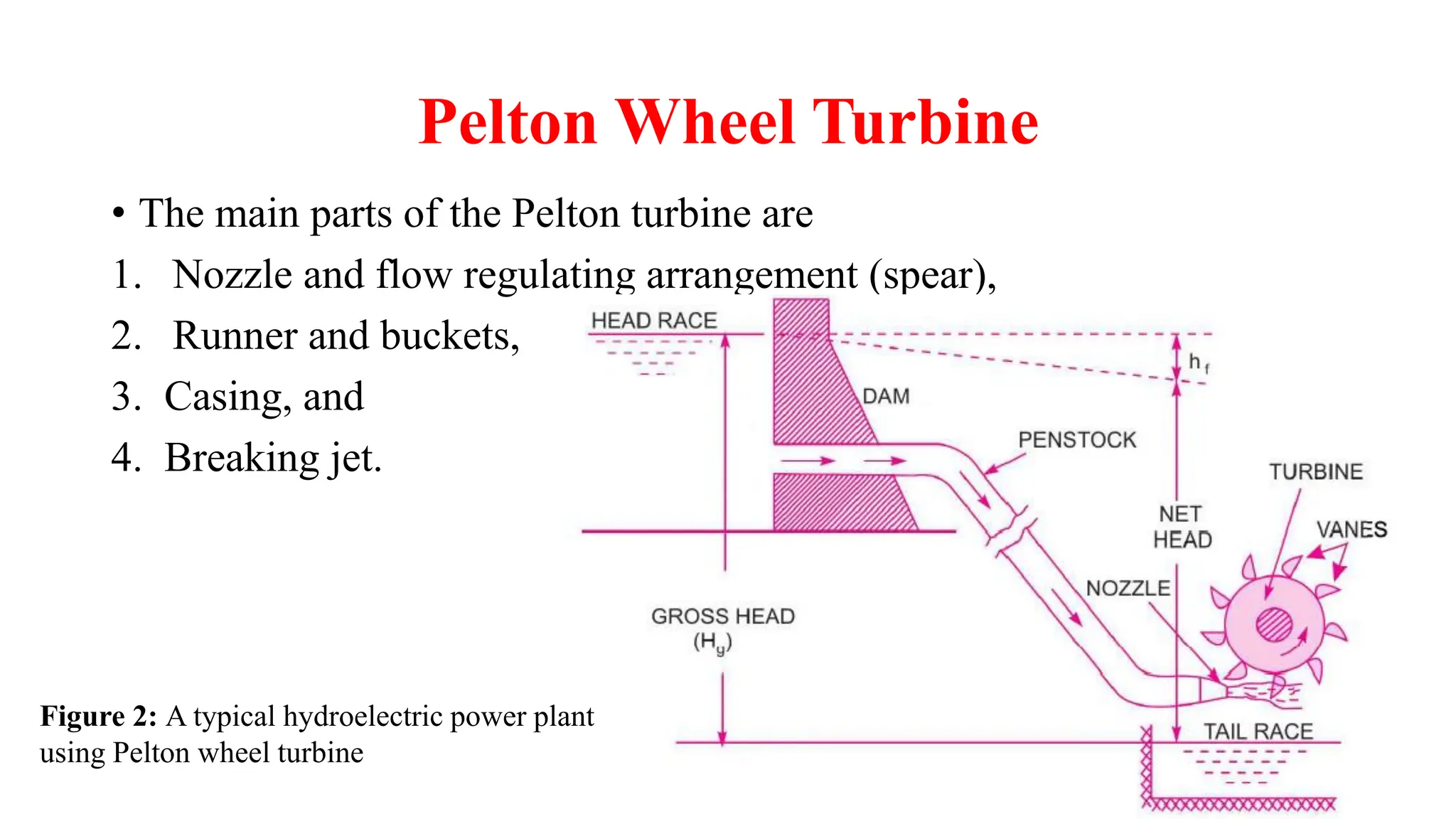

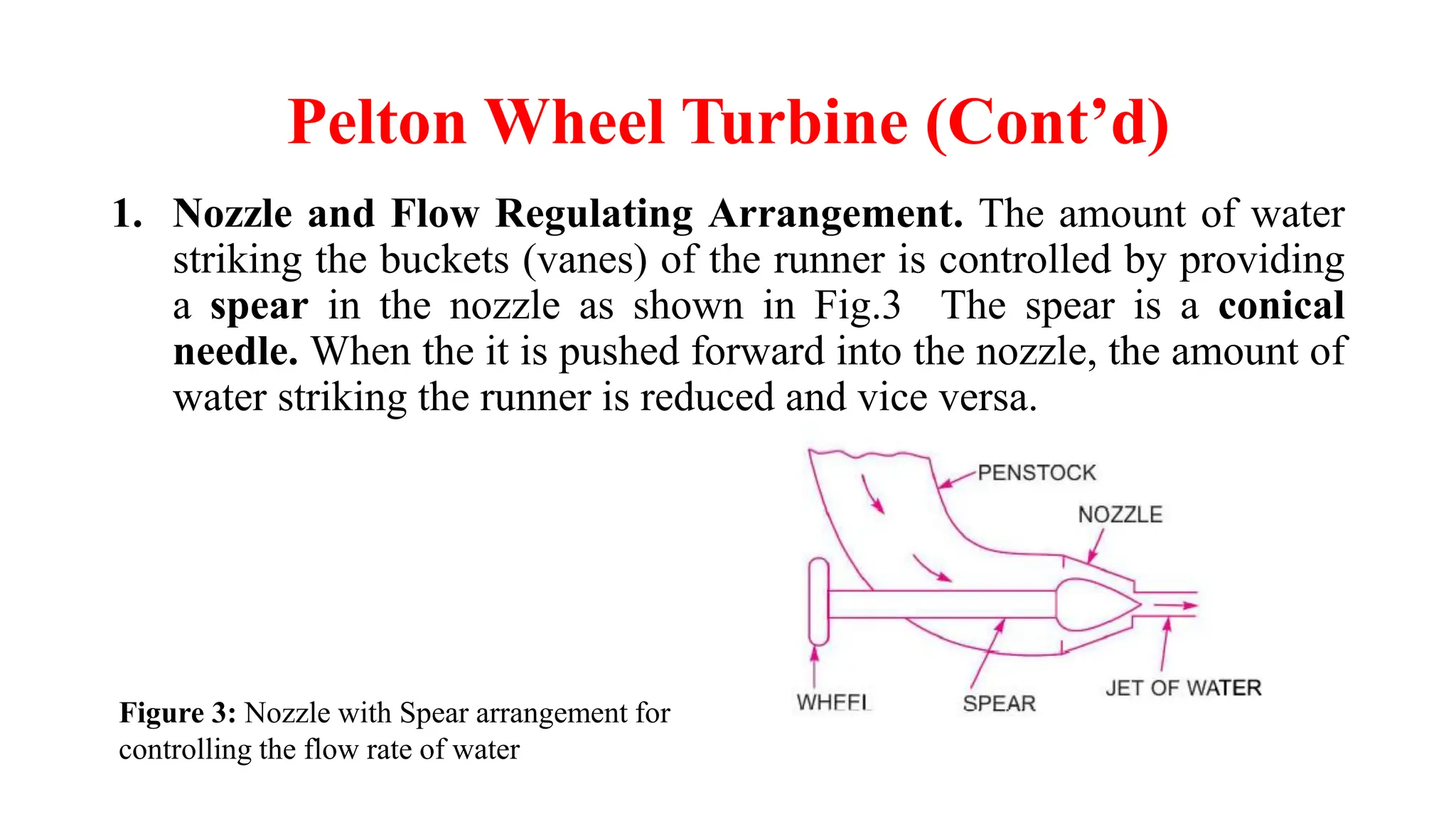

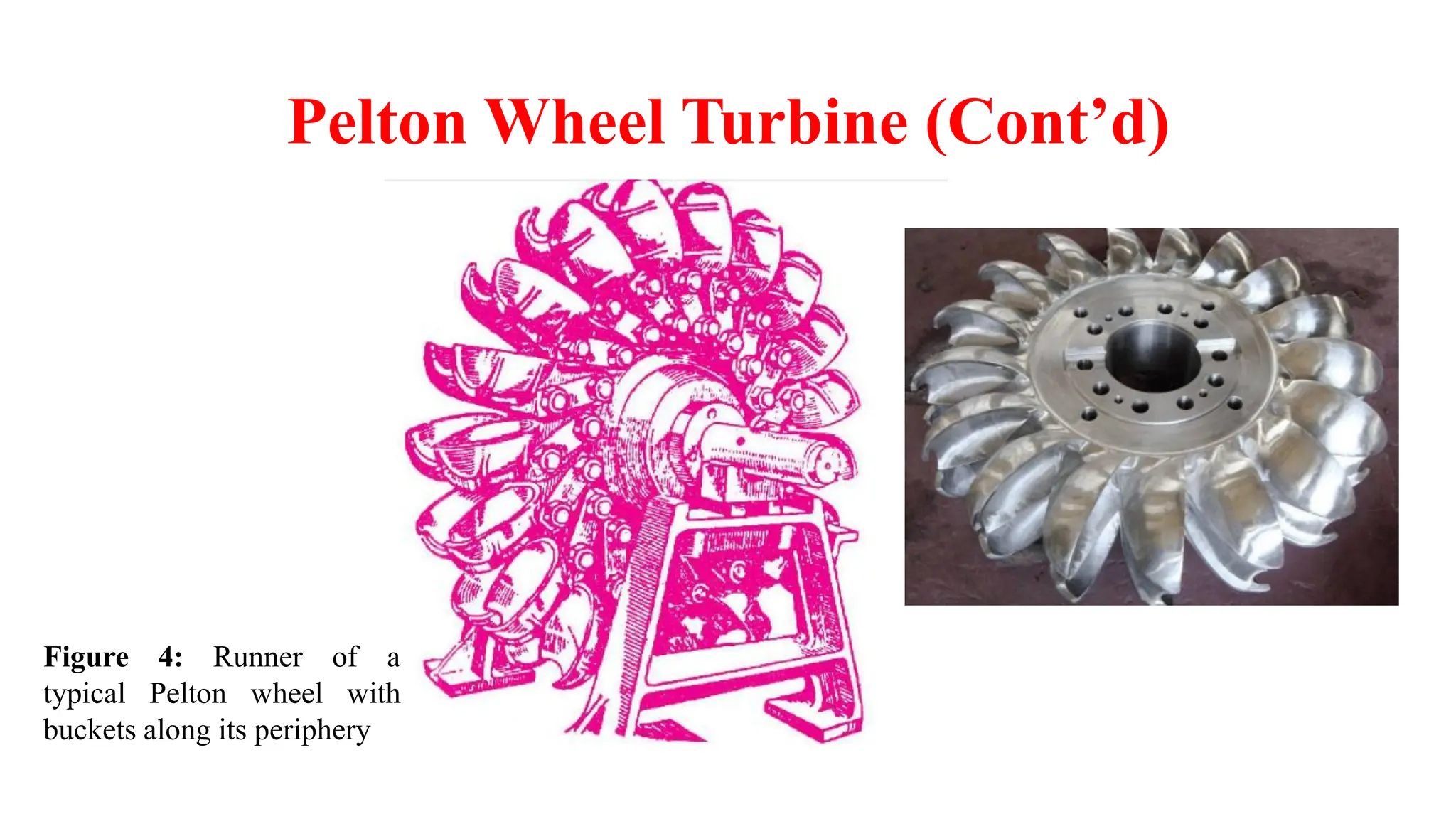

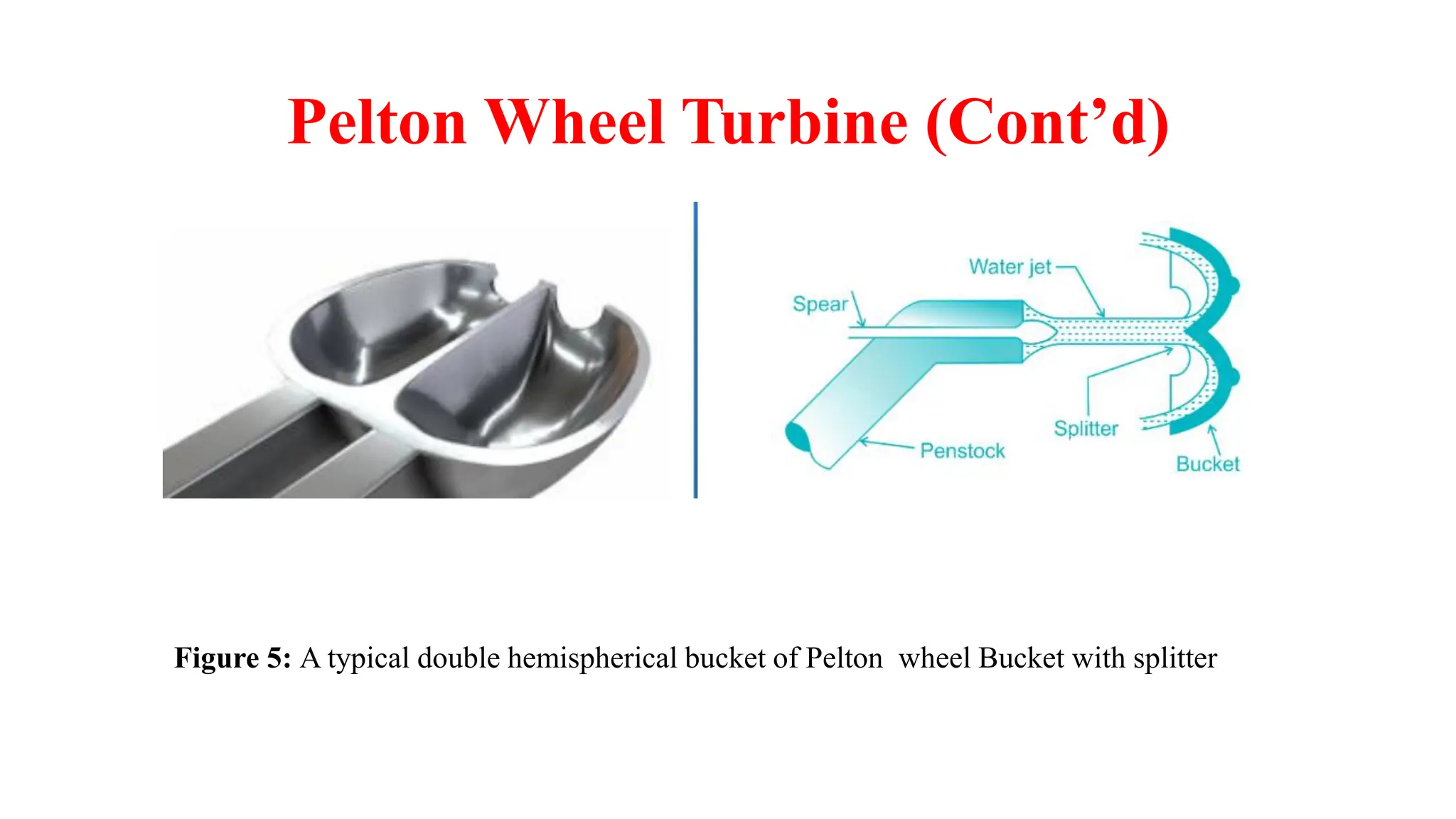

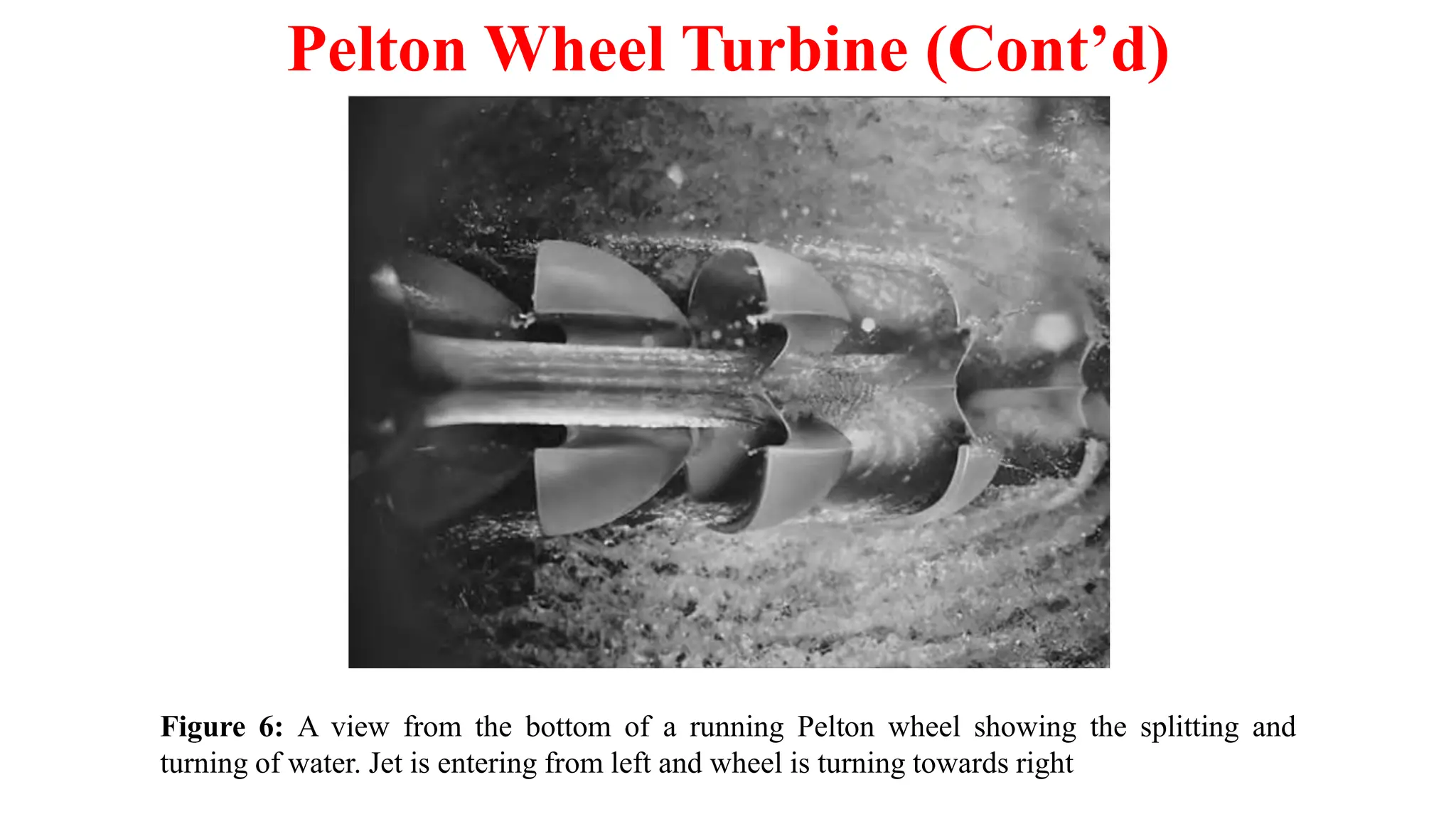

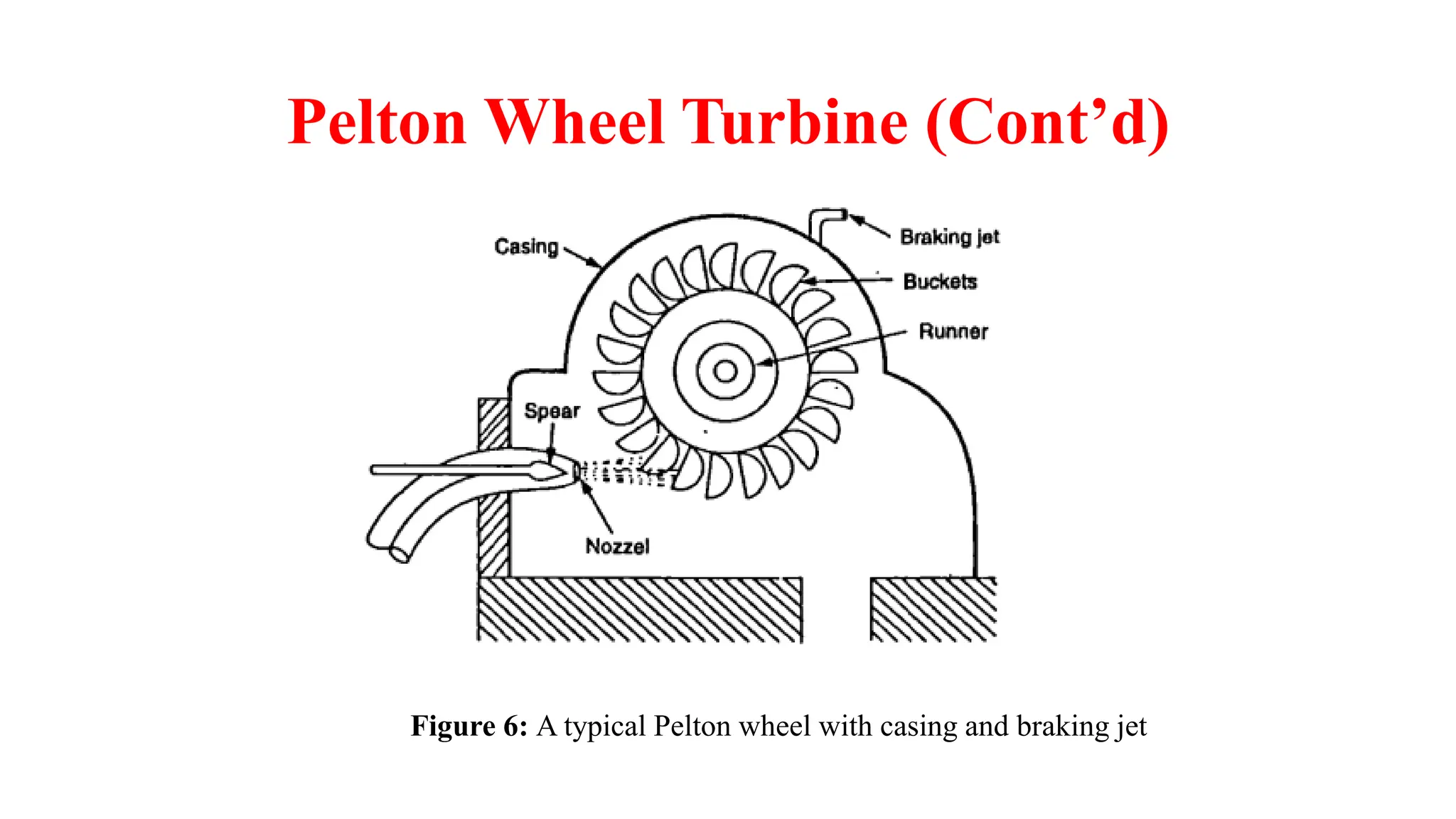

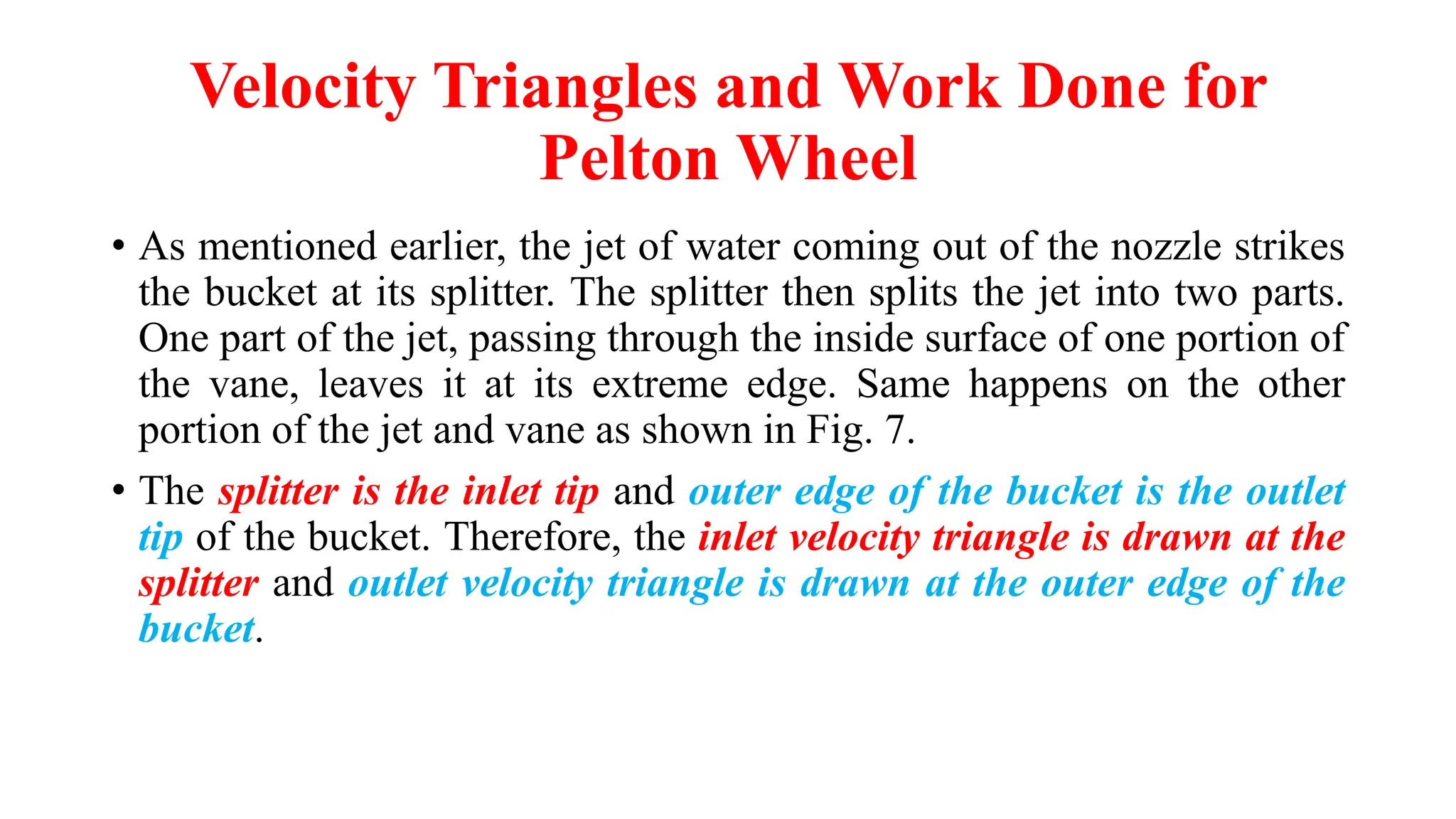

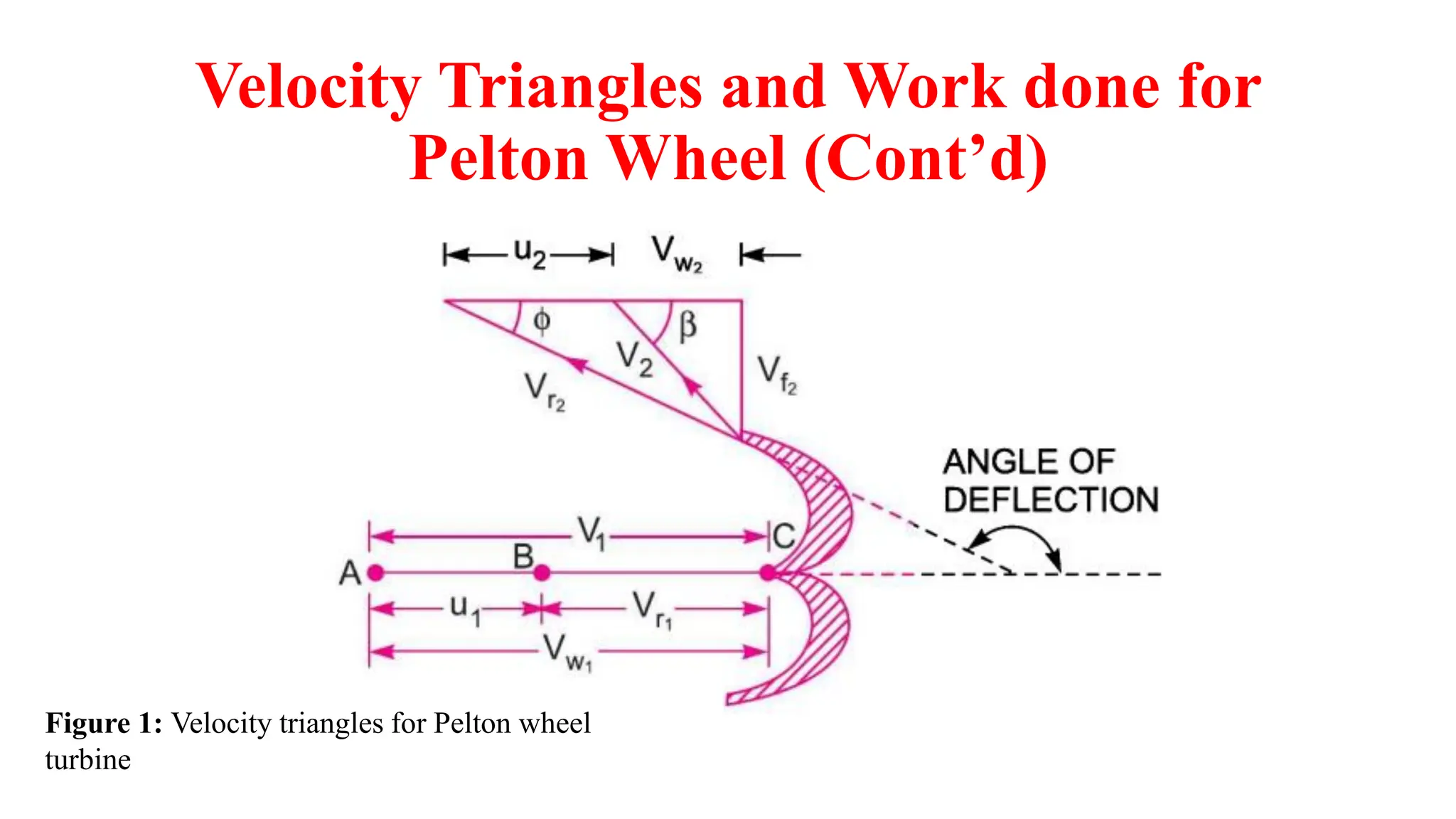

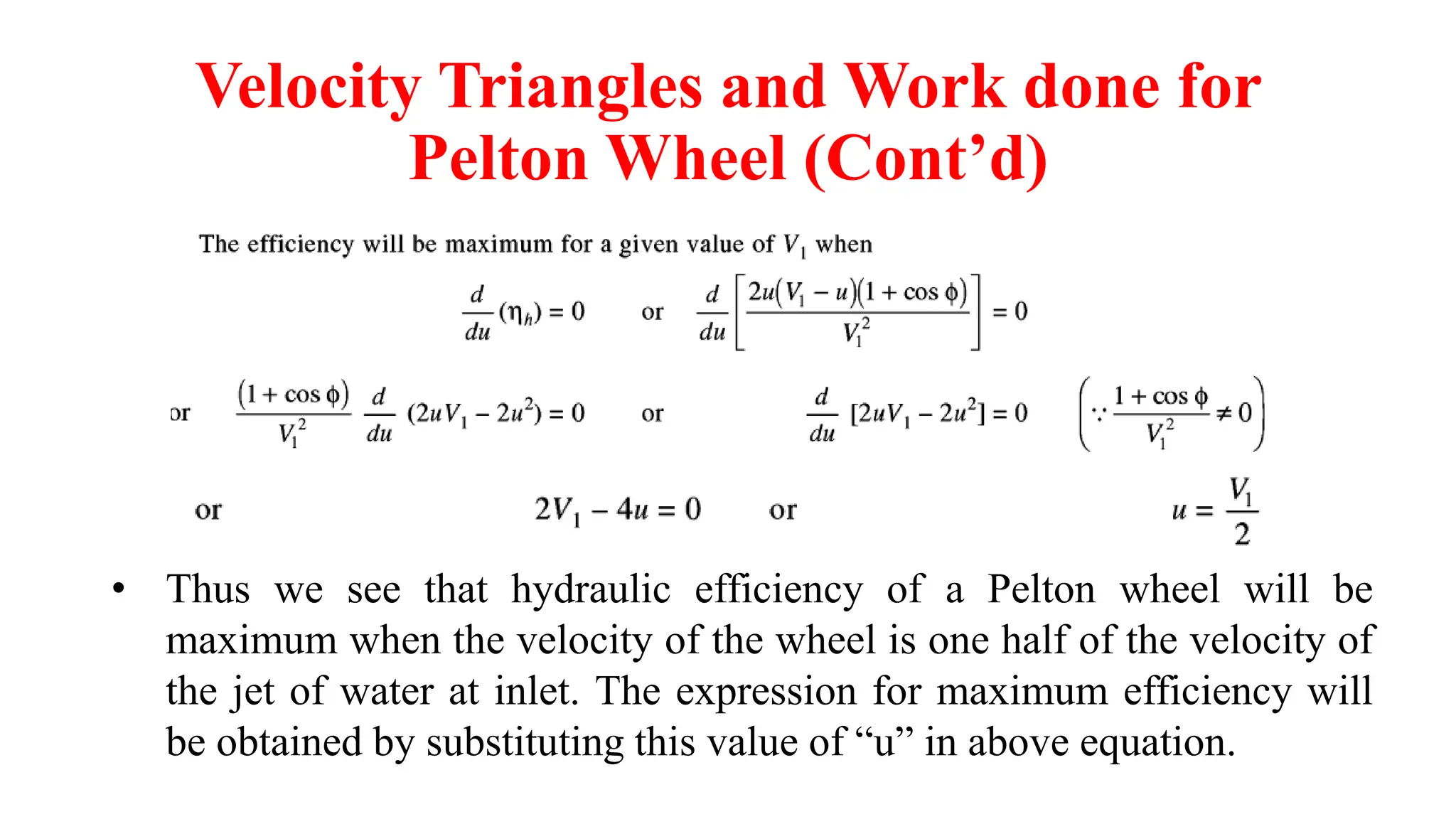

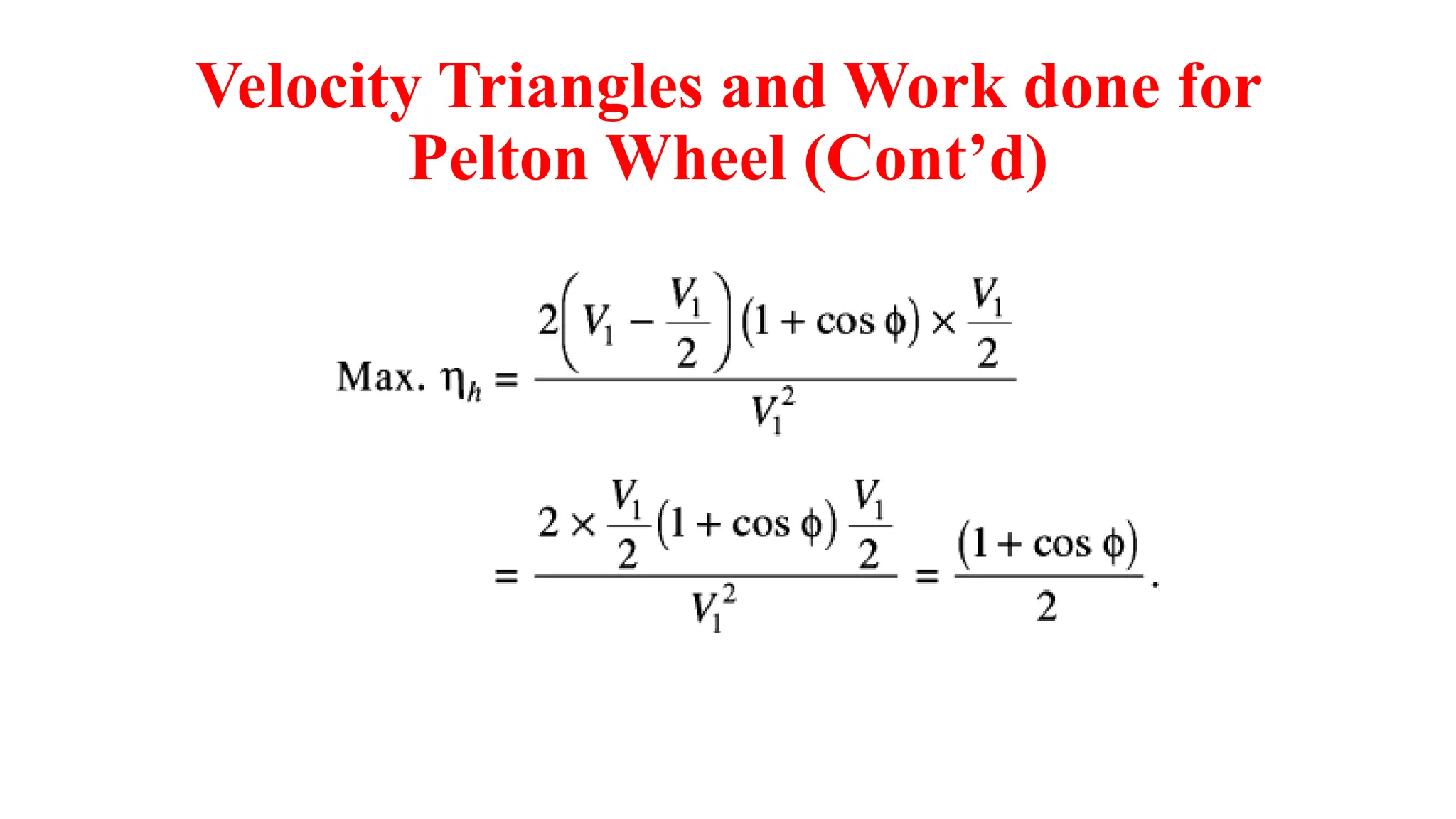

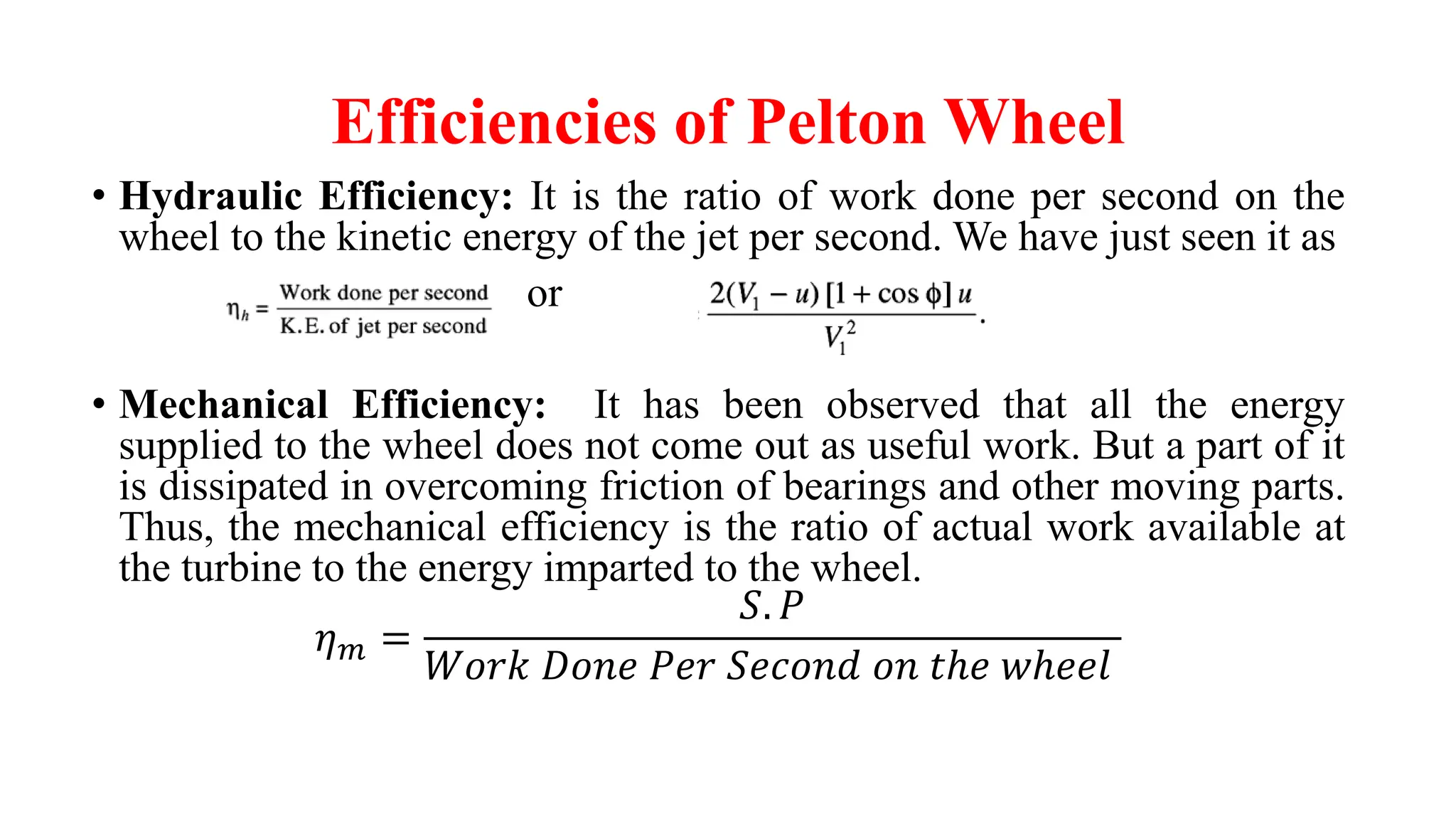

The document provides an overview of turbomachinery, specifically focusing on pumps and turbines, and introduces hydraulic turbines, which convert hydraulic energy into mechanical energy for electricity generation. It explains classifications of hydraulic turbines based on energy types and flow directions, and emphasizes impulse turbines, particularly the Pelton wheel, detailing its components and efficiencies. Moreover, it includes examples and calculations related to the operation and efficiency of Pelton turbines.

![Numerical Problems

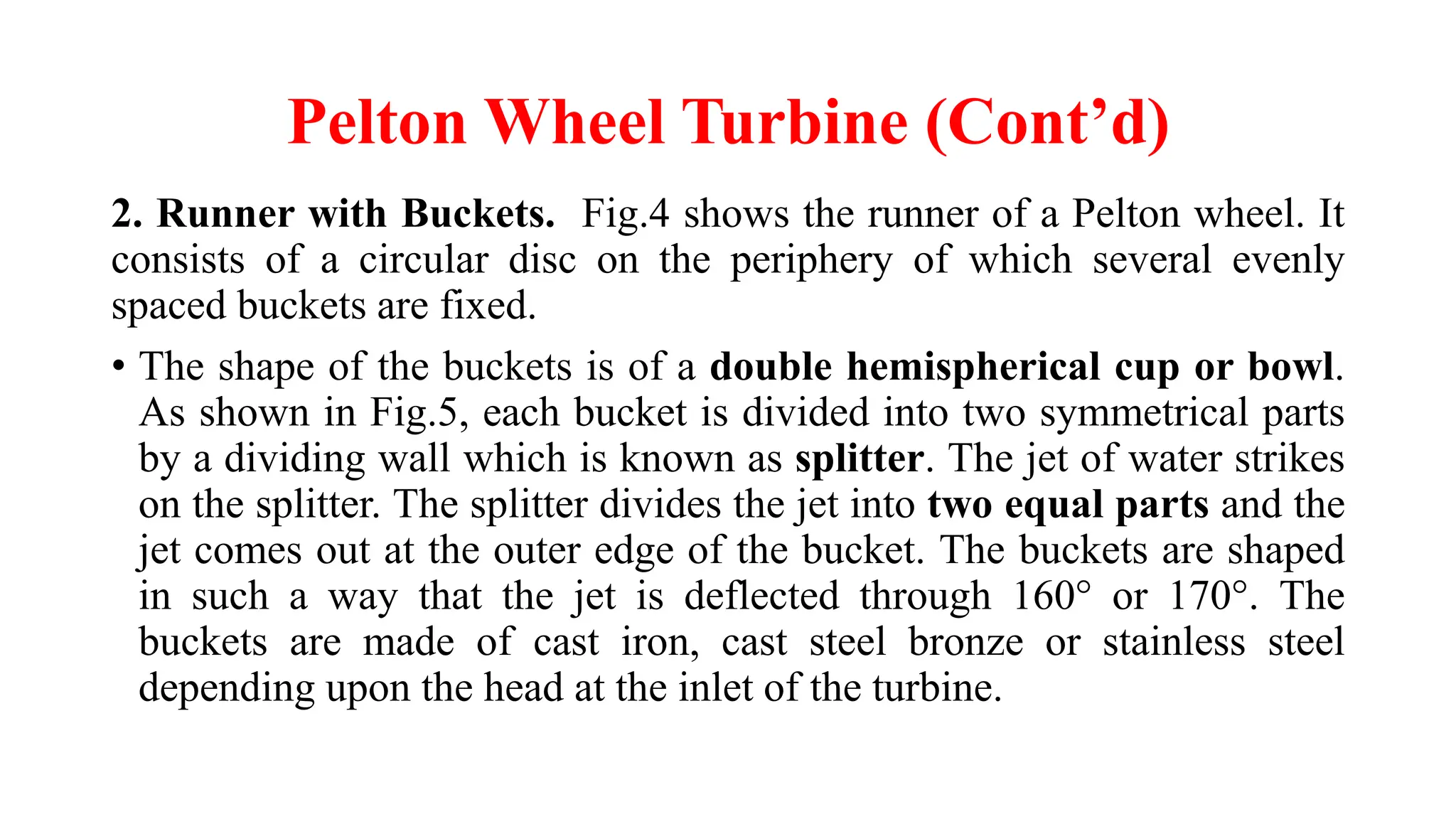

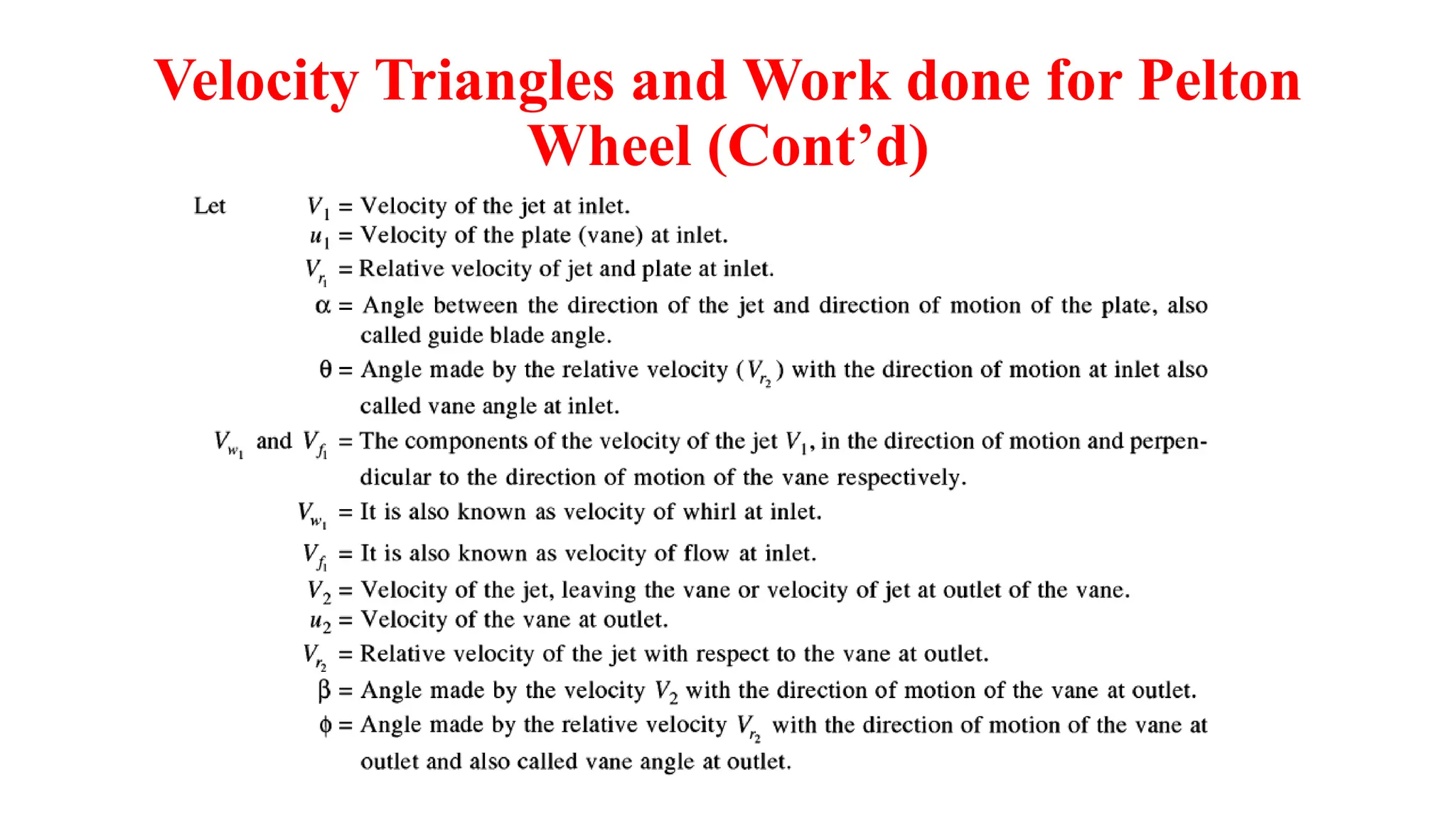

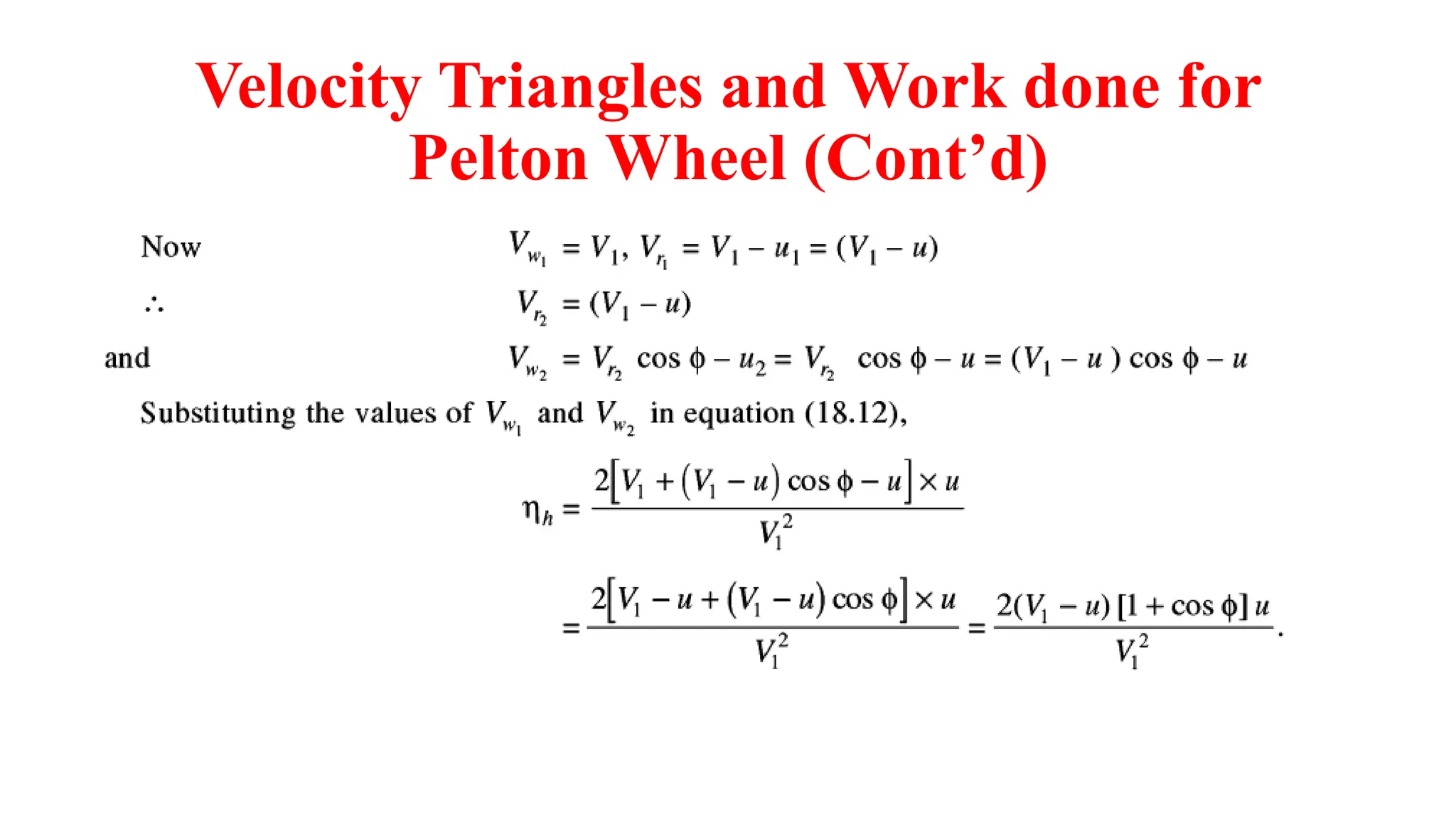

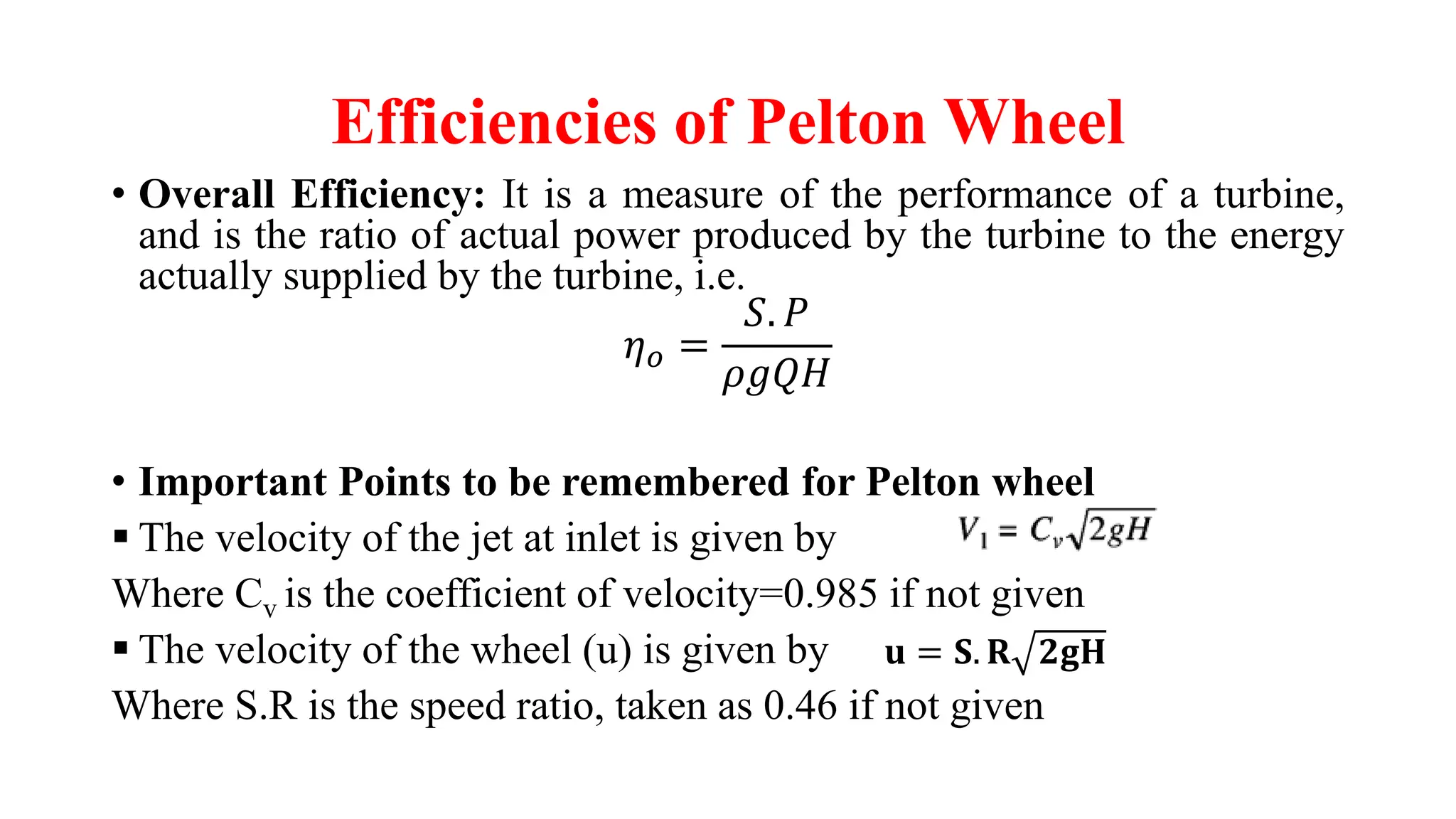

• Problem 1: A Pelton wheel has a mean bucket speed of 10 meters per

second with a jet of water flowing at the rate of 700 liters/s under a

head of 30 meters. The buckets deflect the jet through an angle of

160°. Calculate (i) the power given by water to the runner (work done

per second by the water on the runner blades) and (ii) the hydraulic

efficiency of the turbine. Assume coefficient of velocity as 0.98. [Ans:

(i)186.97 kW (ii) 94.54%]

• Problem 2: A Pelton wheel is having a mean bucket diameter of 1 m

and is running at 1000 r.p.m. The net head on the Pelton wheel is 700

m. If the side clearance angle is 15° and discharge through nozzle is

0.1 m3/s, find: (i) Power available at the inlet of the nozzle, and (ii)

Hydraulic efficiency of the turbine. [Ans: (i) 686.7 kW, (ii) 97.18%]](https://image.slidesharecdn.com/fm-iiweek1-241002175908-61b736dc/75/FM-II-Week-1-pdf-of-mechanical-engineerinf-of-fluid-mechanics-29-2048.jpg)