This document discusses various techniques for repairing structures including:

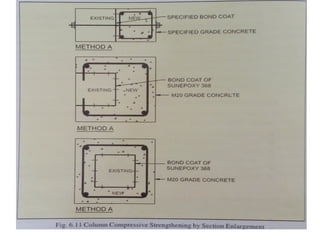

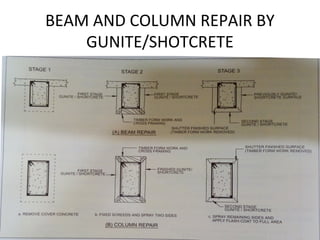

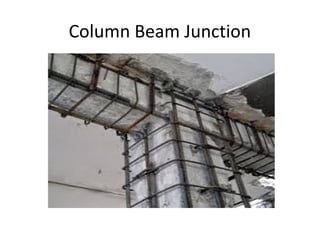

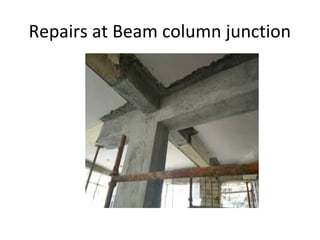

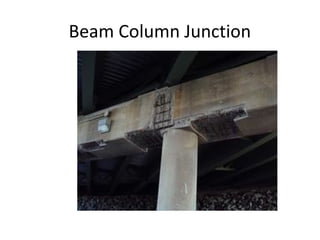

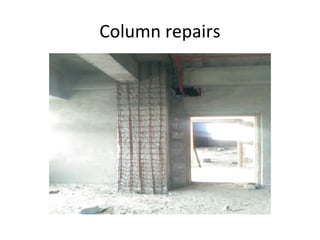

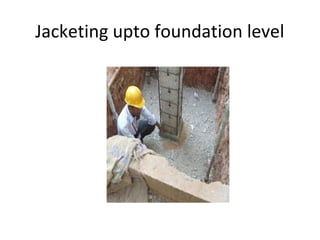

- Jacketing and section enlargement to strengthen columns.

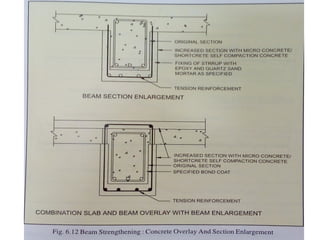

- Enlarging the compression zone and adding reinforcement to strengthen beams.

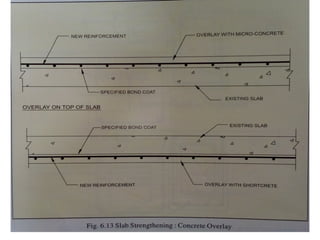

- Providing overlays or underlays to strengthen slabs.

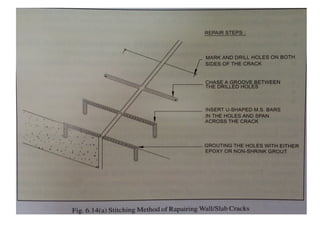

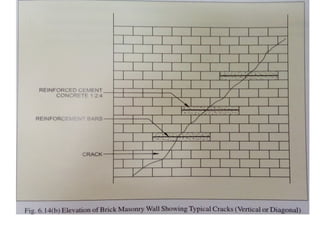

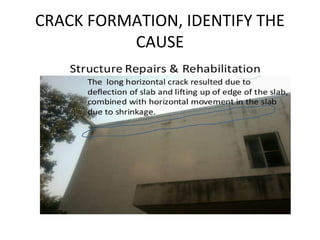

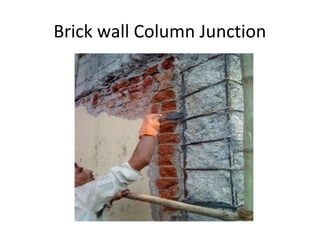

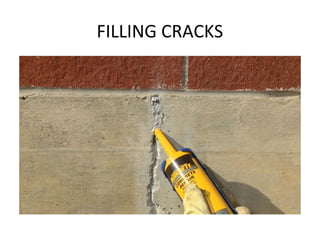

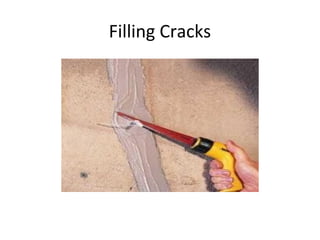

- Stitching cracks in walls and slabs by inserting reinforcing bars across cracks.

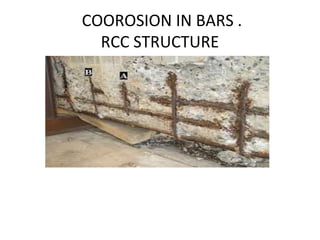

- Removing corroded concrete and rebar from structures and applying protective coatings.

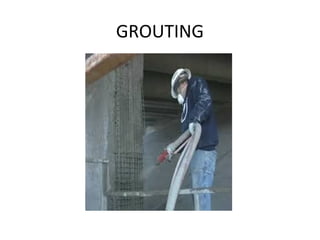

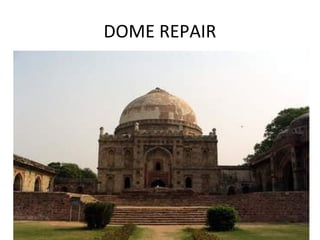

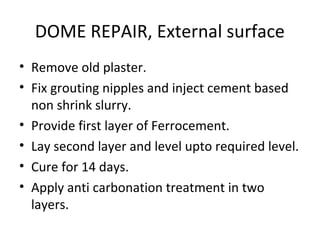

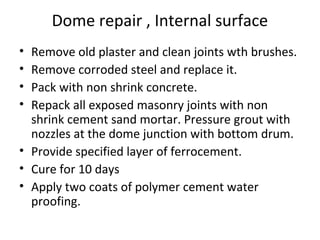

- Repairing domes by removing old plaster, injecting cracks, adding ferrocement layers, and applying waterproofing treatments.