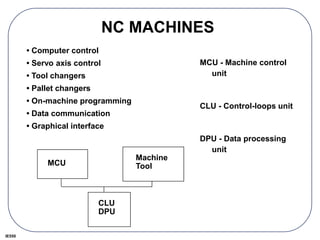

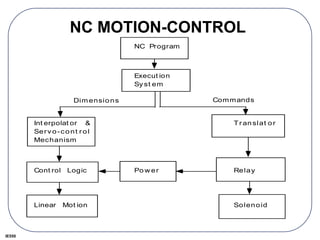

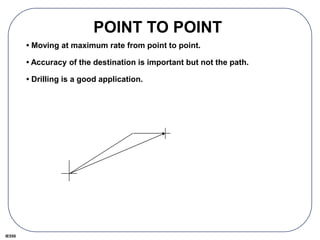

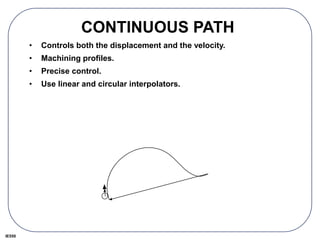

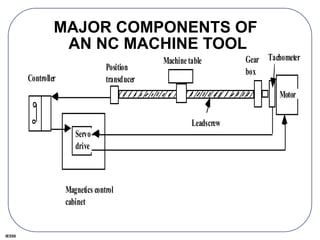

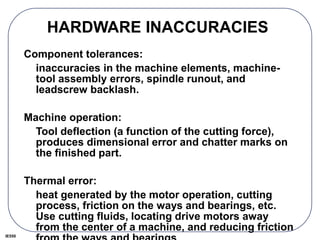

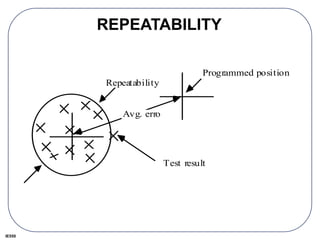

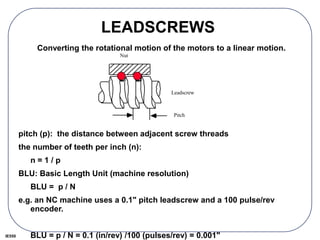

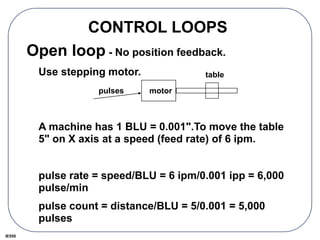

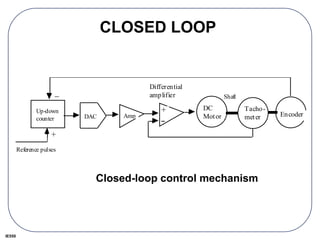

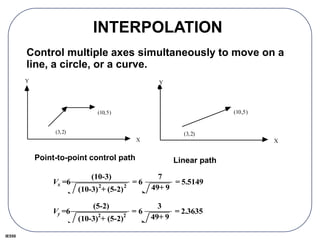

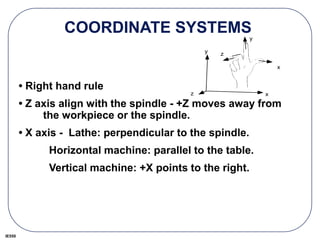

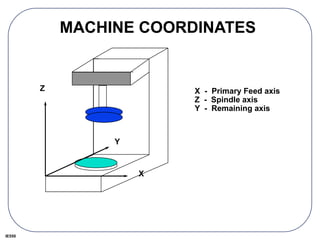

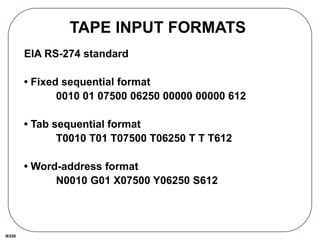

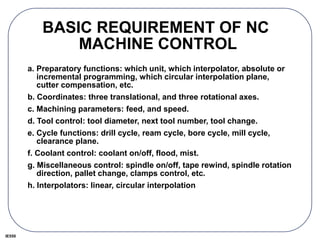

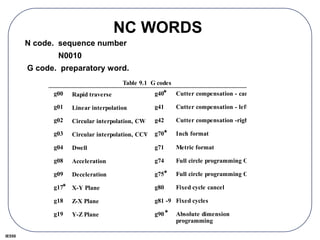

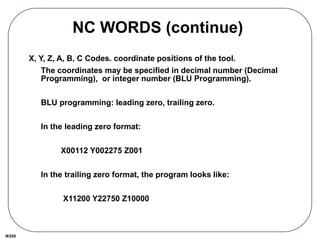

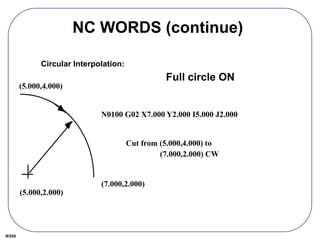

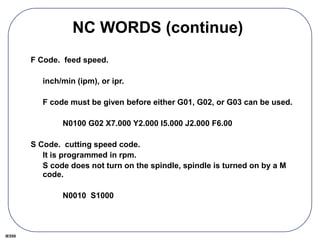

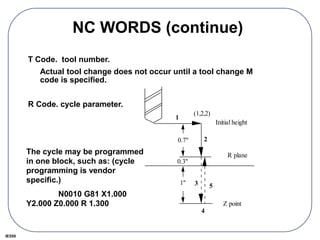

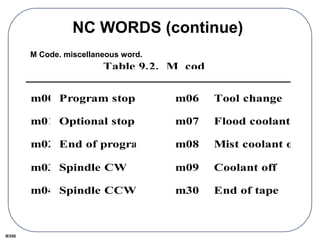

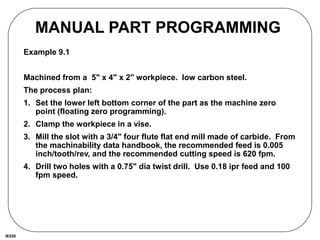

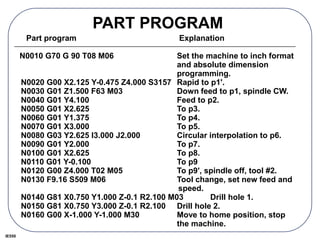

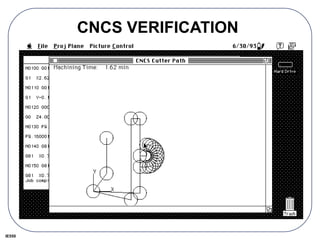

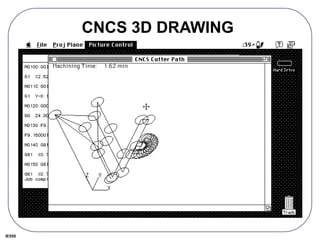

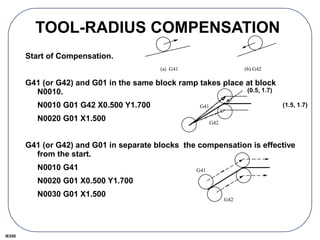

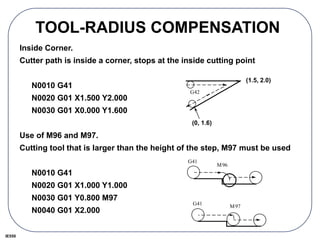

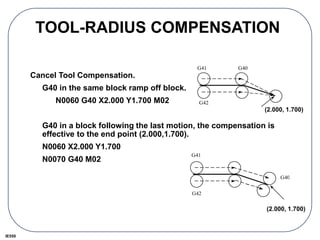

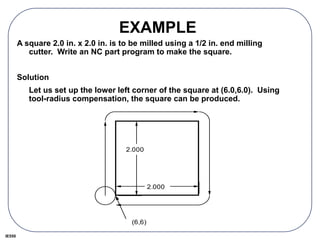

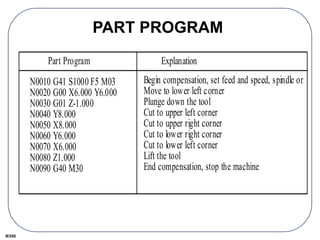

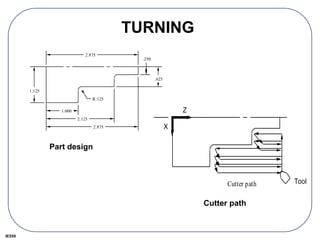

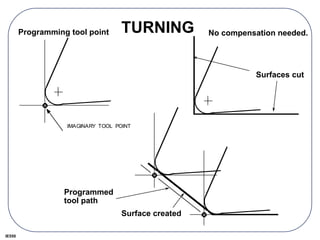

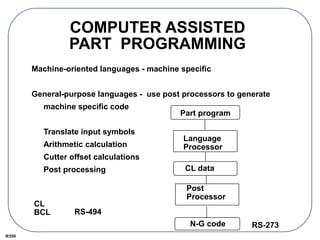

The document provides information on numerical control (NC) and computer numerical control (CNC) machines. It discusses the historical development of NC machines and how they have evolved from mechanized production equipment using cams and stops to programmable automation using NC, PLC and robotics. It then describes the major components, motion control, classifications and accuracy/repeatability of modern NC machines. The document also covers point-to-point and continuous path control, interpolation methods, programming codes and tool compensation techniques for NC machines.