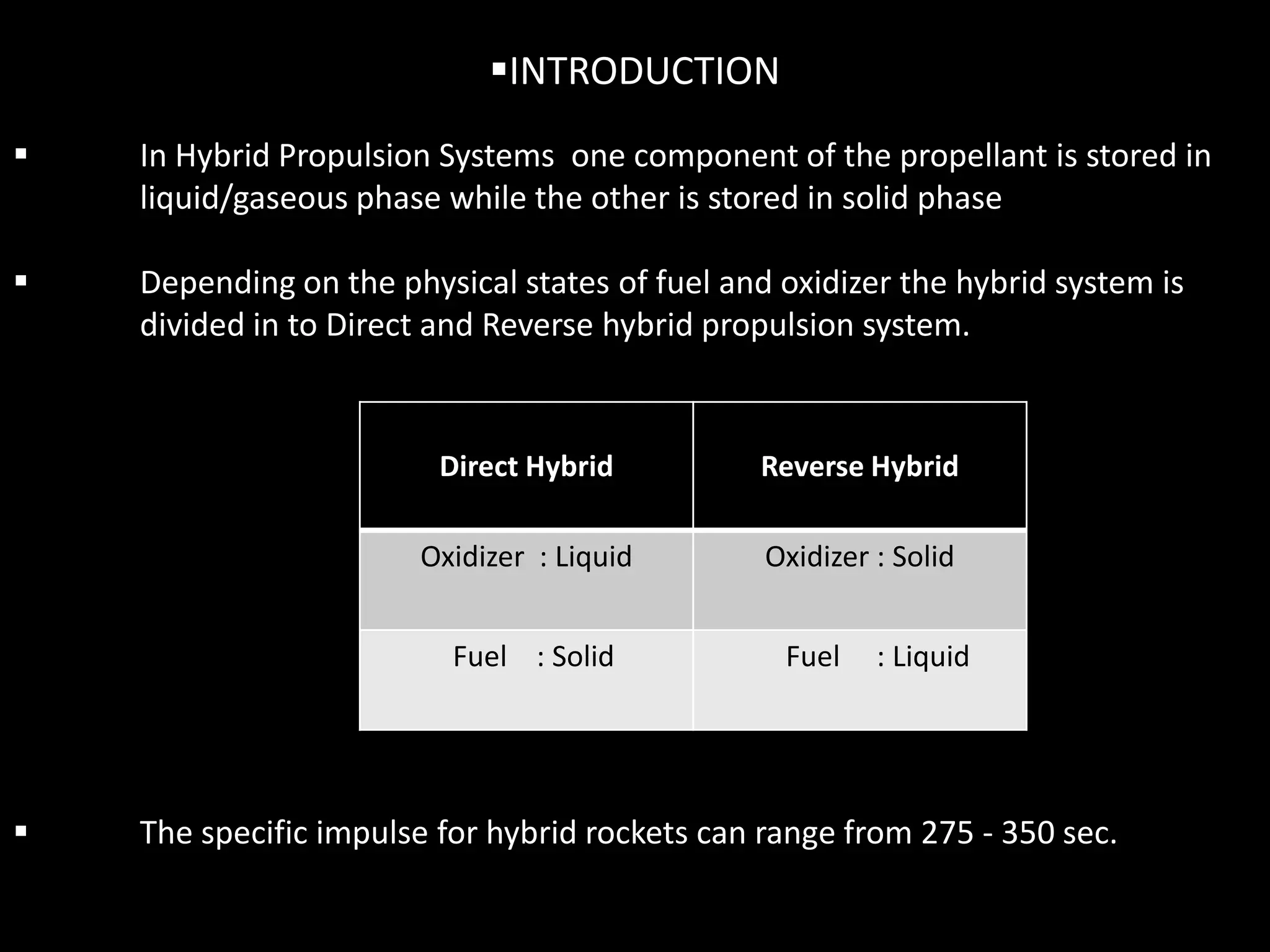

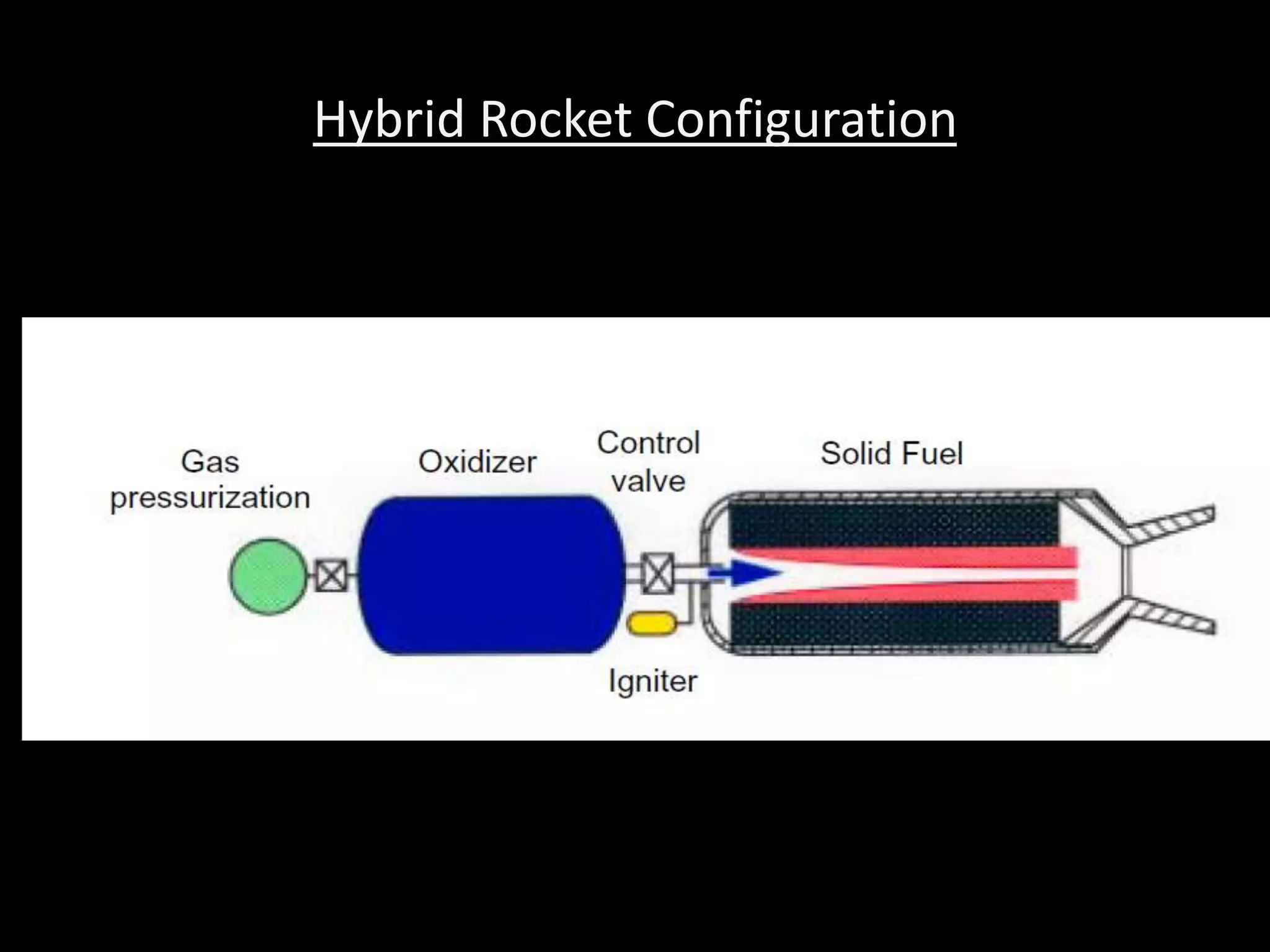

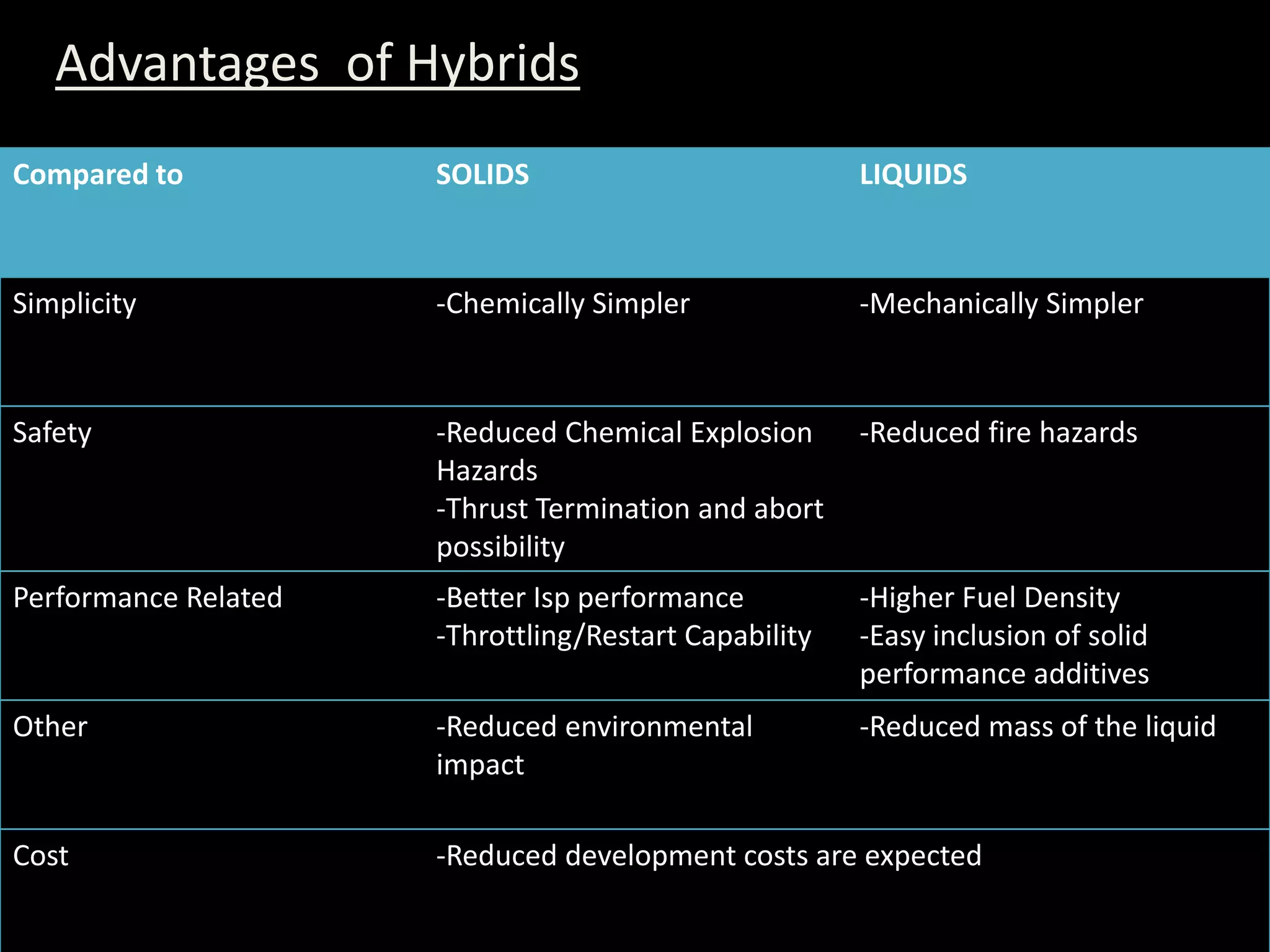

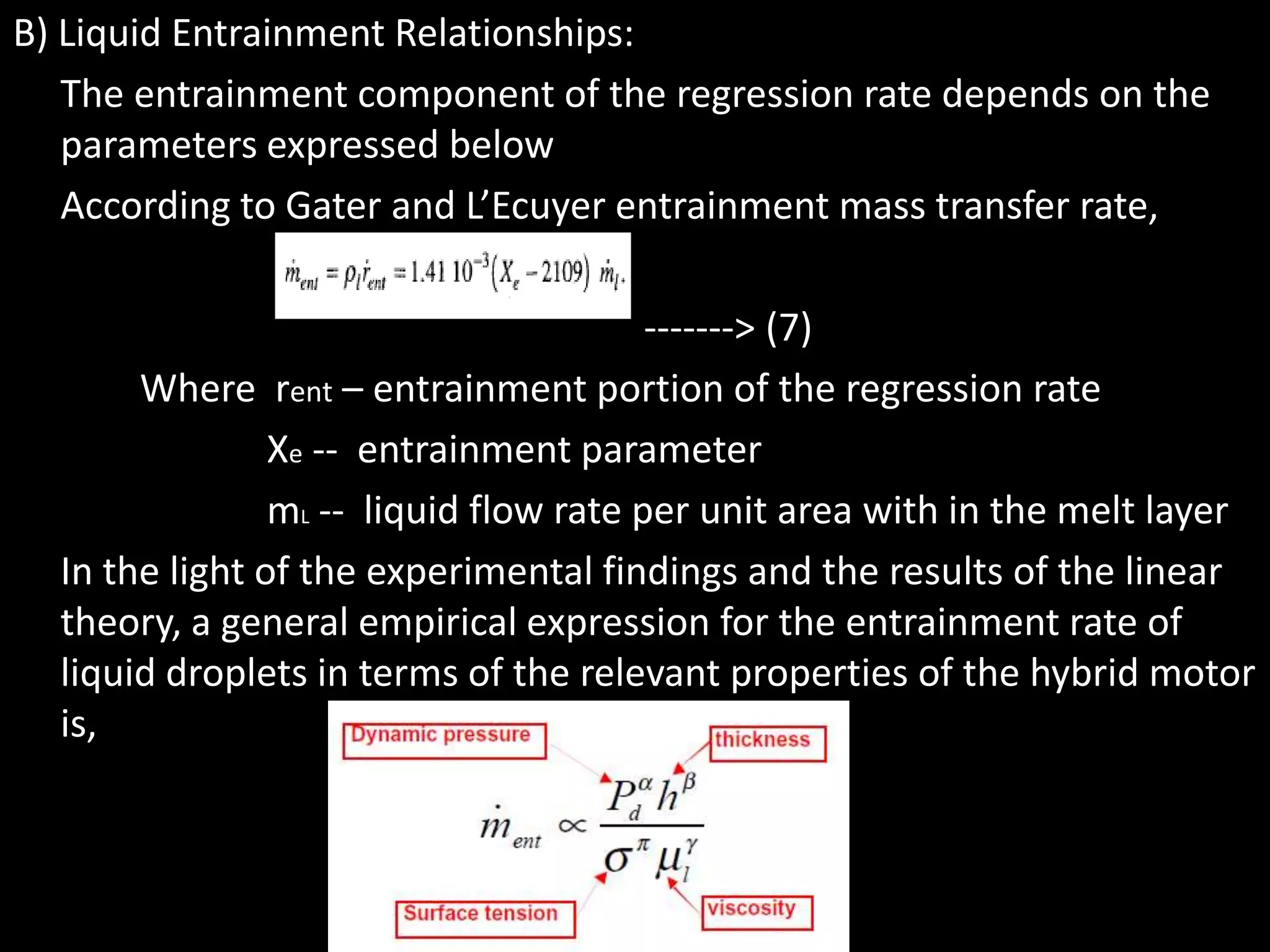

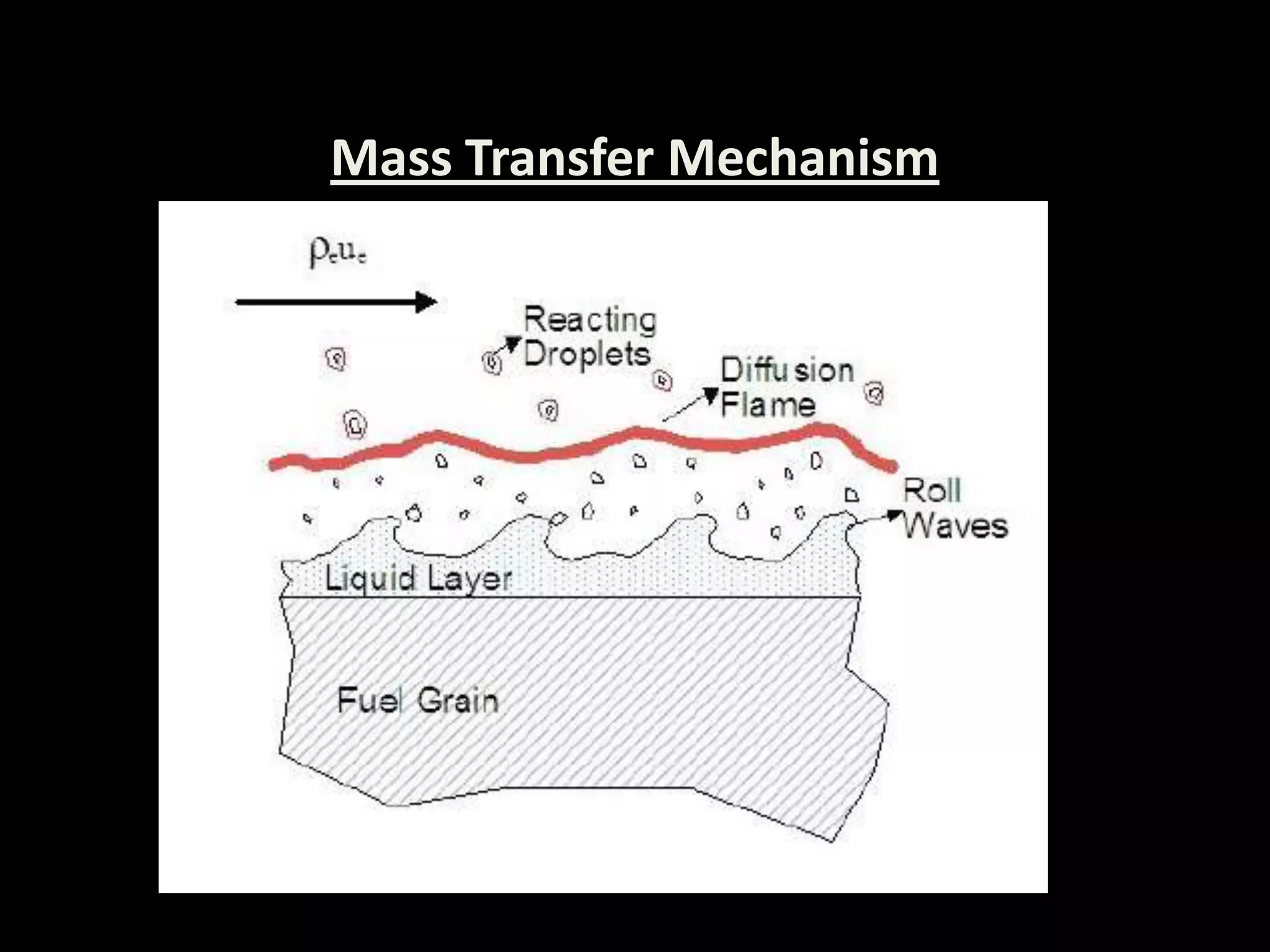

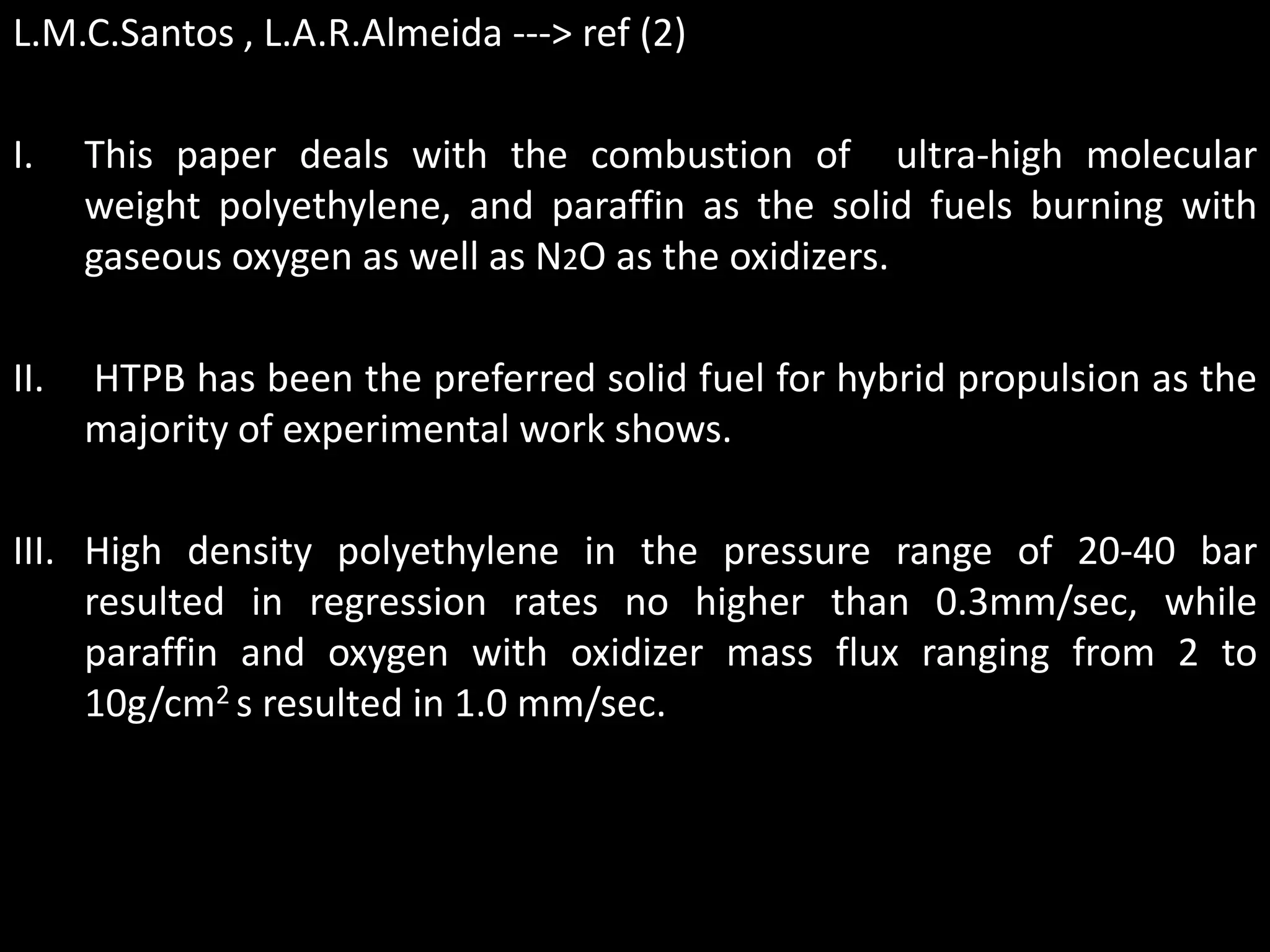

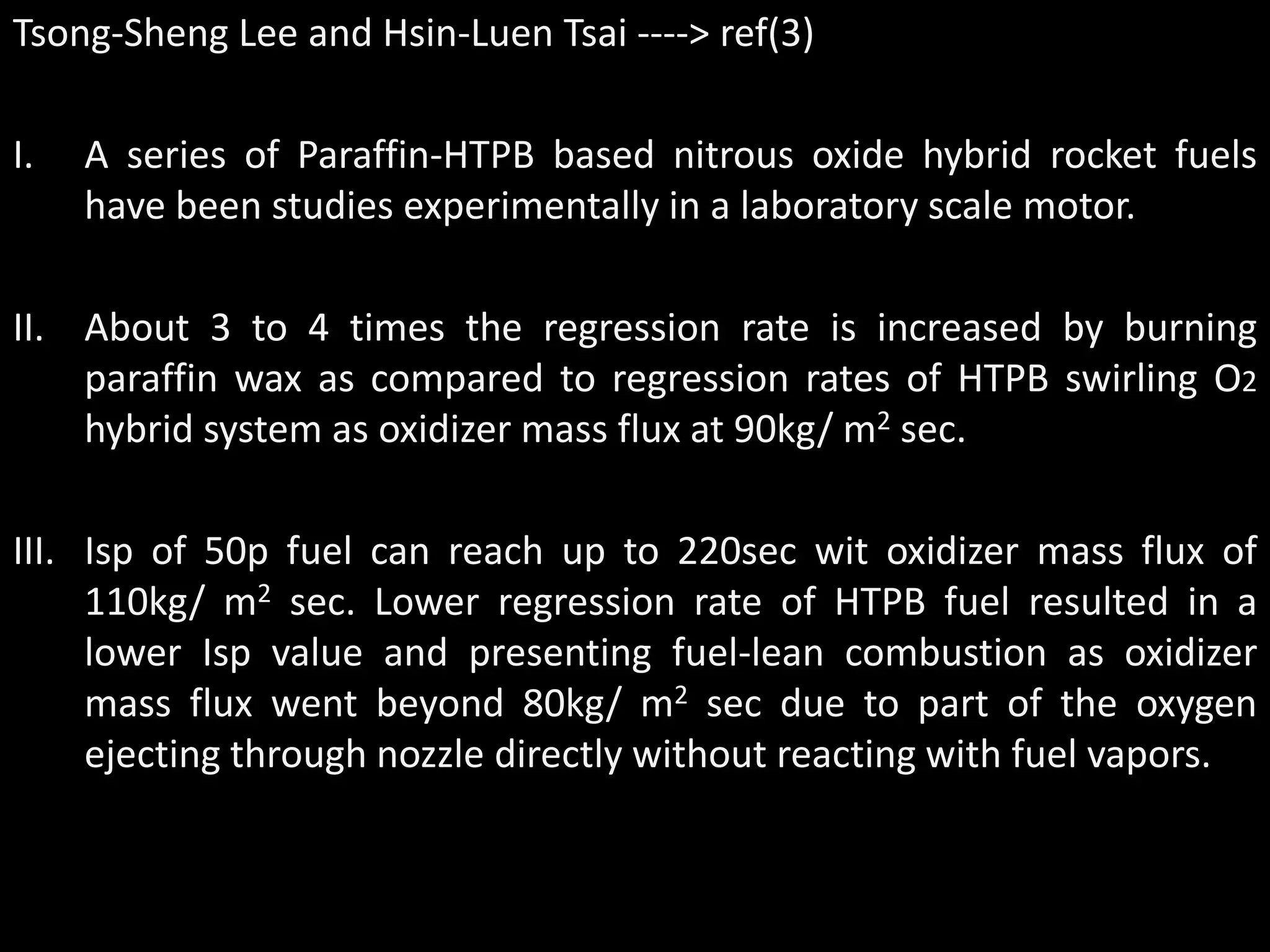

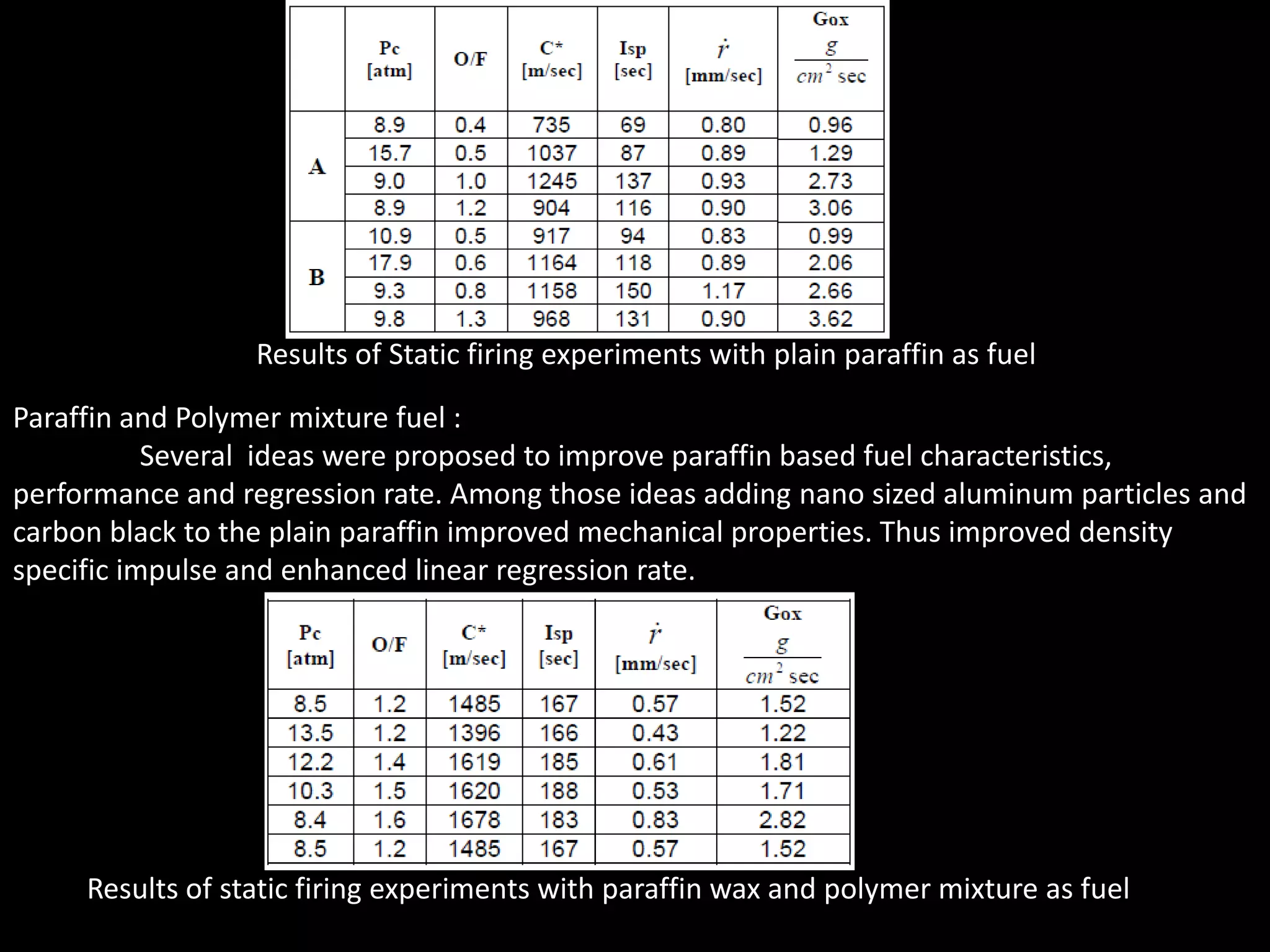

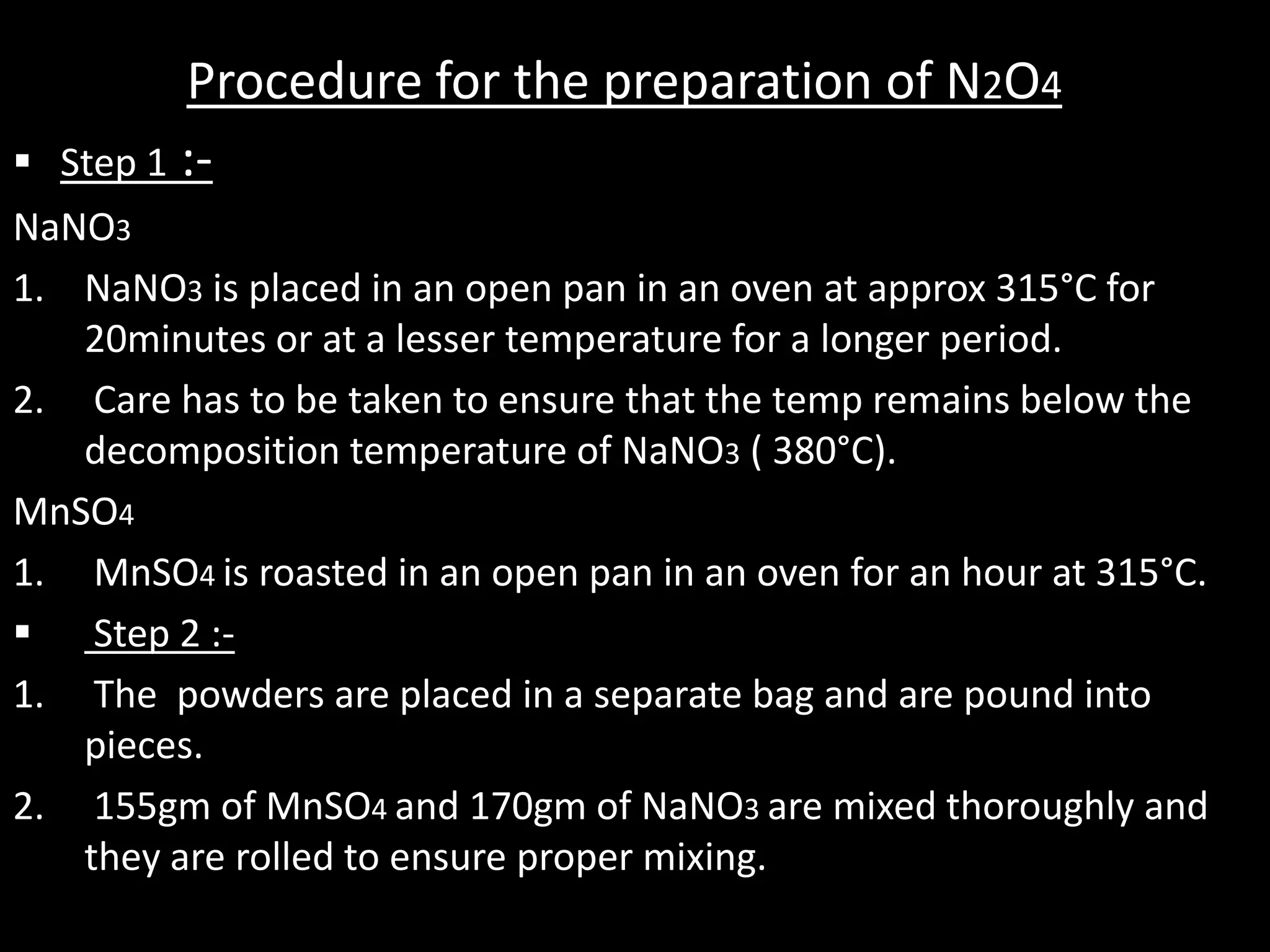

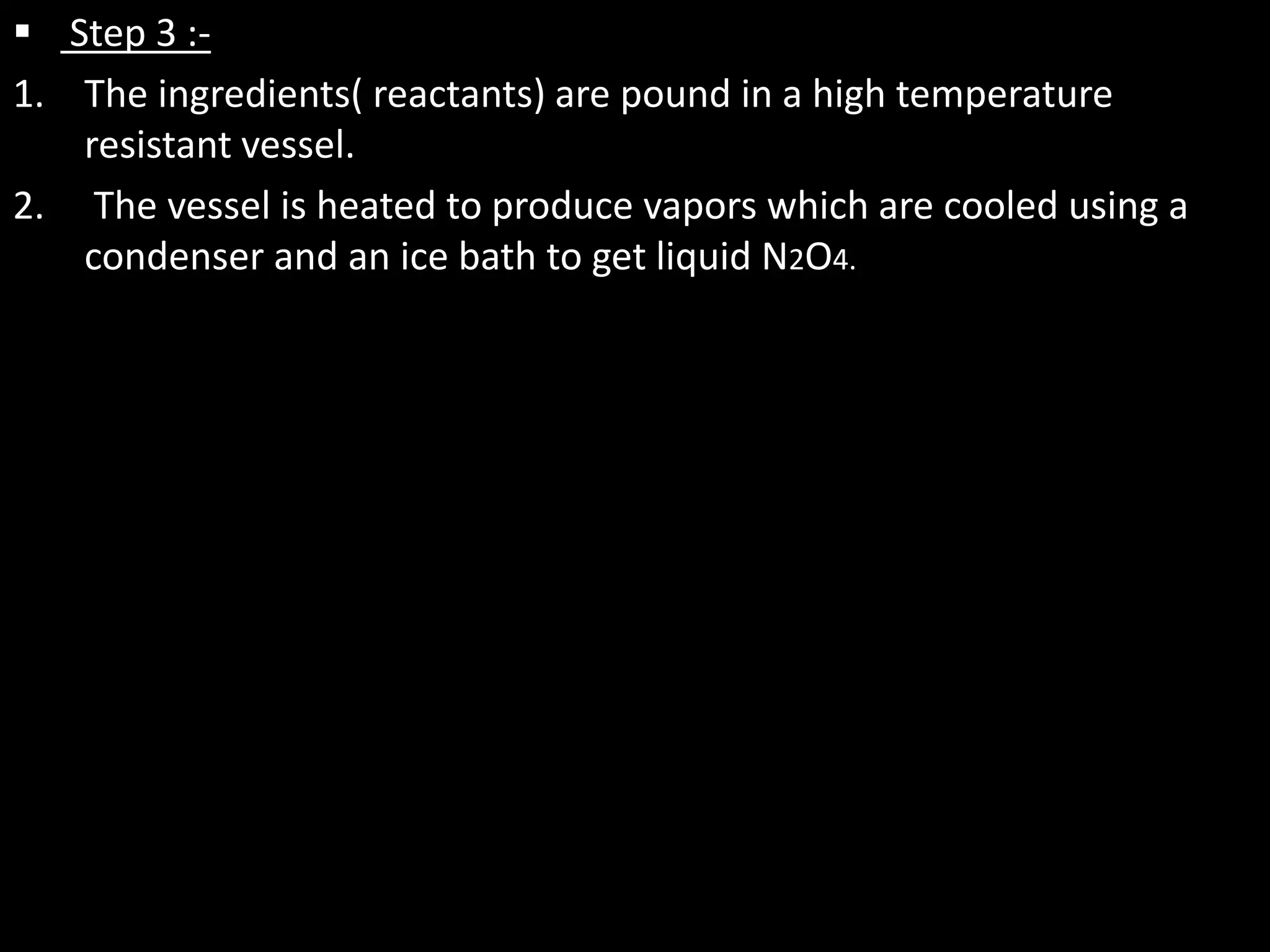

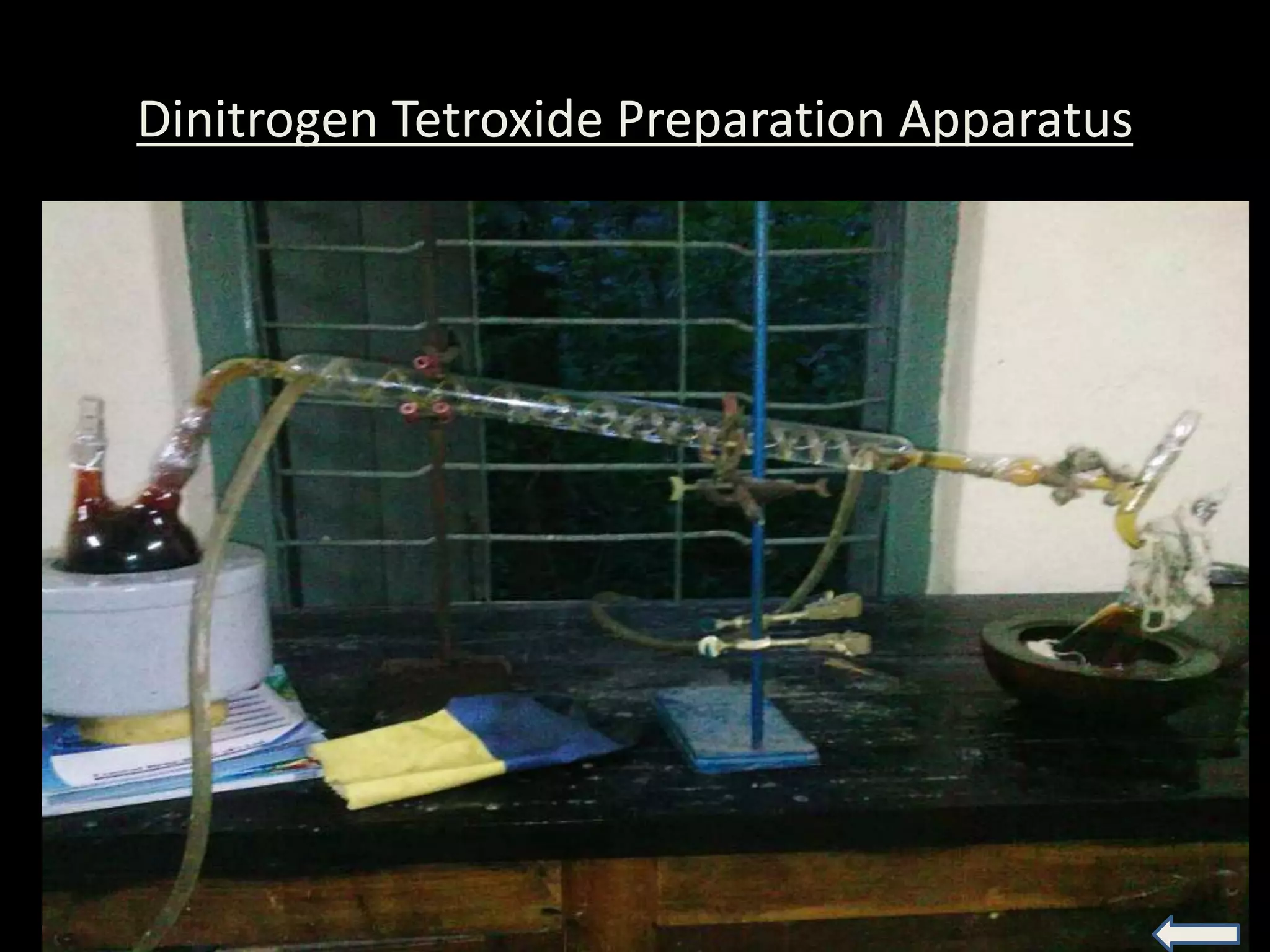

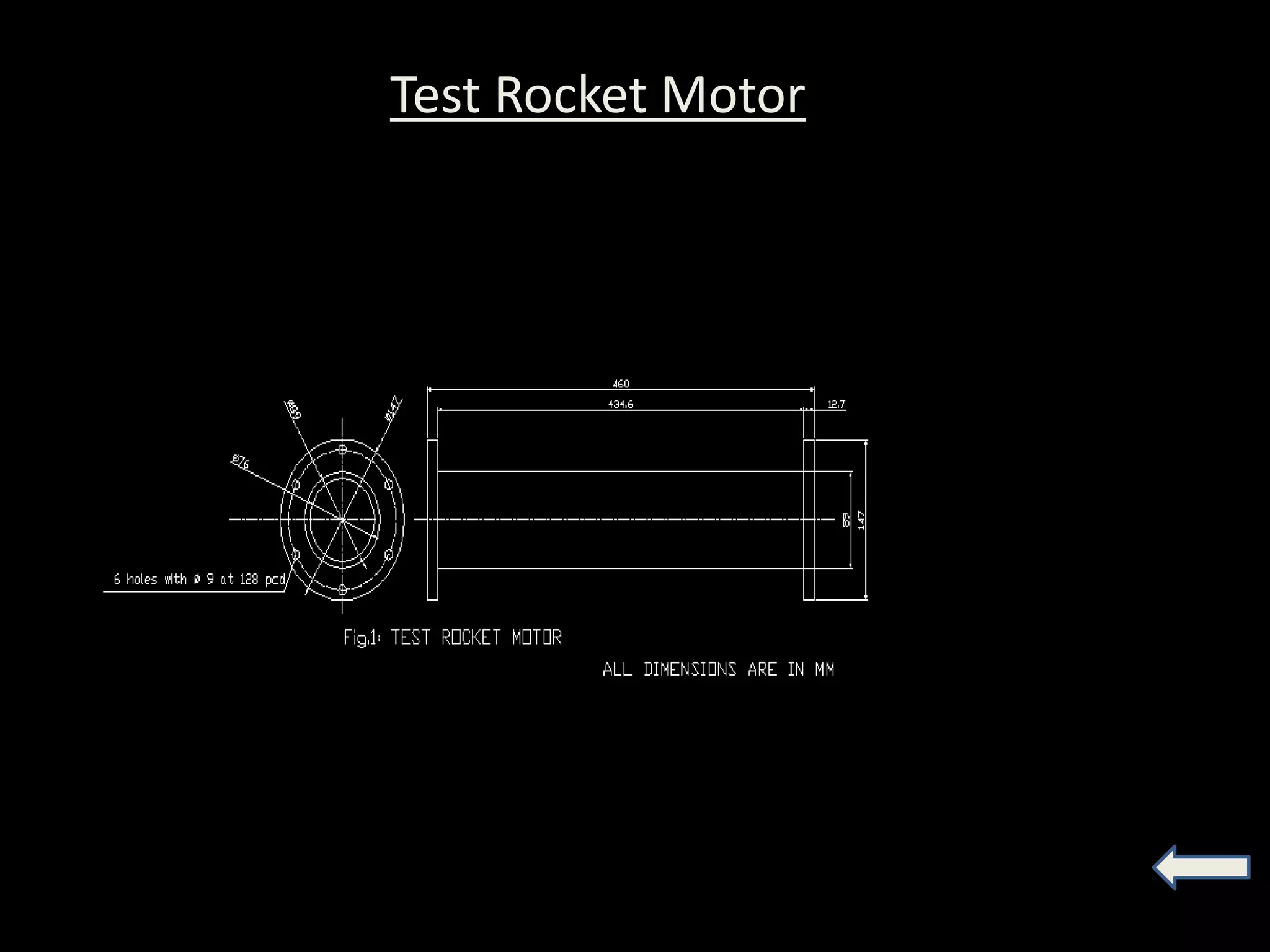

The document summarizes research on using paraffin wax as the solid fuel and N2O/N2O4 as the oxidizer in a hybrid rocket system. It discusses the advantages and disadvantages of hybrid systems compared to liquid and solid fuel systems. The document reviews literature on hybrid rocket regression rates and combustion characteristics. It outlines the objectives and methodology of experiments to study the regression rate, mass consumption rate, motor pressure-time history, thrust, and specific impulse of the paraffin wax/N2O hybrid system.