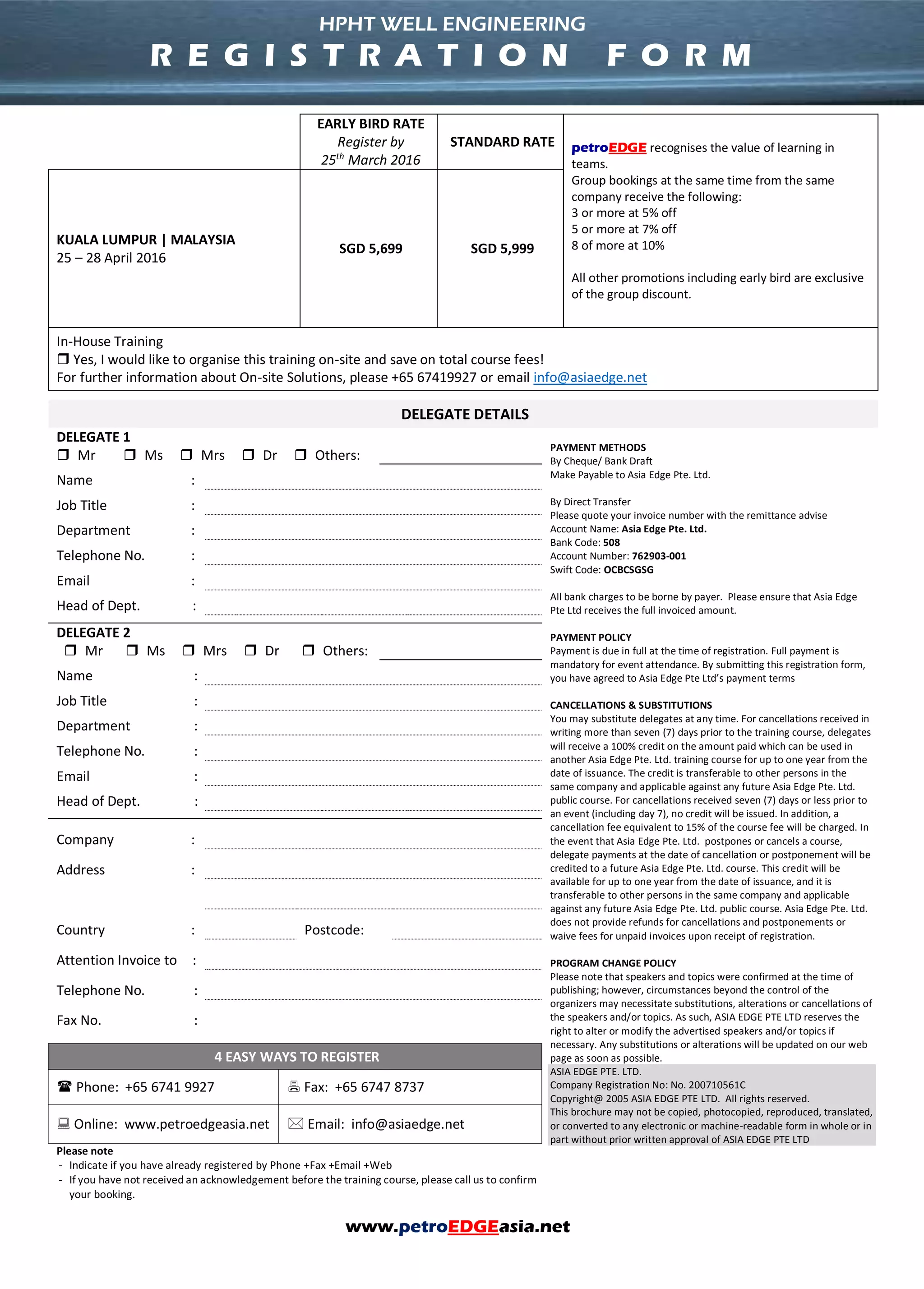

The HPHT Well Engineering course, scheduled from April 25-28, 2016, in Kuala Lumpur, aims to equip participants with knowledge and skills related to high-pressure, high-temperature wells. Attendees will learn about well design, operational planning, rig selection, well control, and various challenges associated with HPHT environments. The course is targeted at professionals with significant experience in conventional well design and delivery, focusing on advanced techniques and practices for safe drilling in HPHT conditions.