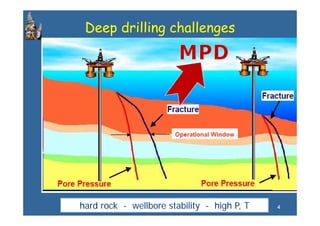

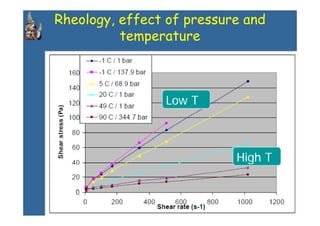

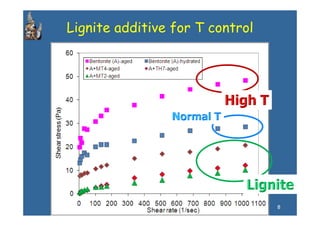

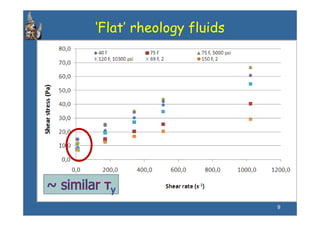

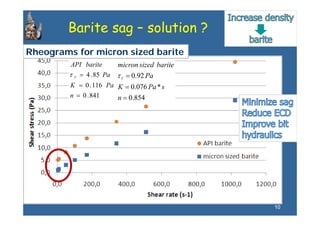

Developing smart drilling fluids that can adapt to harsh downhole conditions with extreme pressures and temperatures over 7,000 meters deep is challenging. Drilling fluid must maintain stable density and rheology at these conditions while transporting cuttings and cooling drill bits. Improved rheological models and hydraulics modeling are needed to better predict downhole pressure and optimize fluid properties. Additives also need to be developed that can withstand the hostile environments encountered during deep drilling.