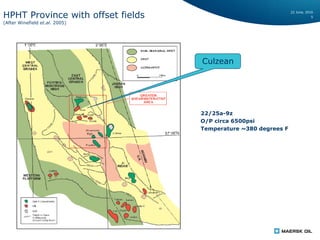

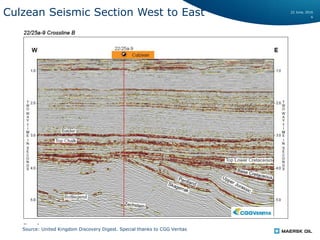

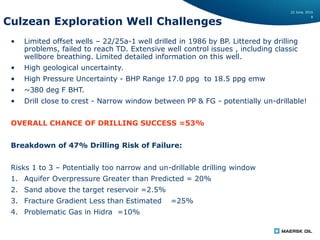

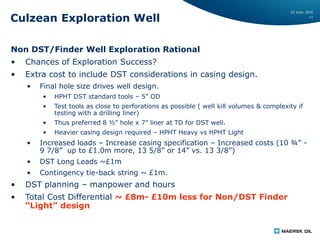

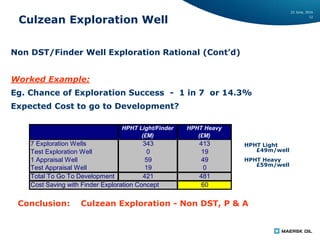

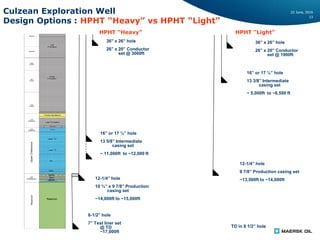

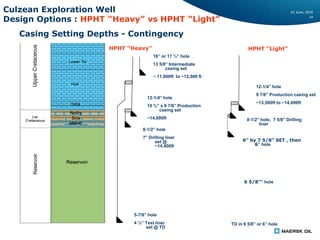

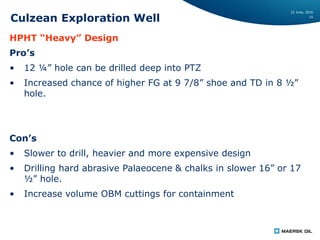

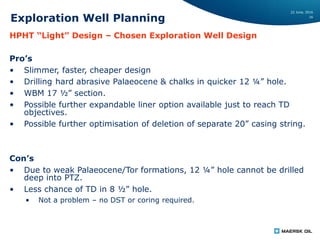

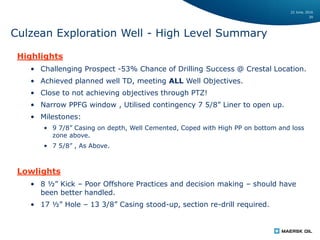

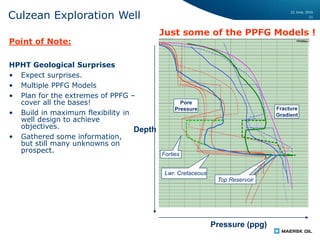

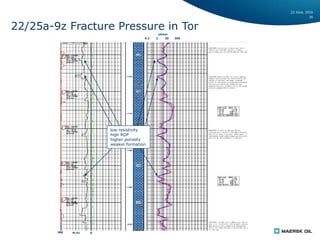

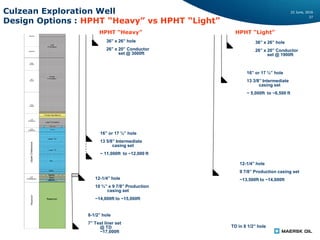

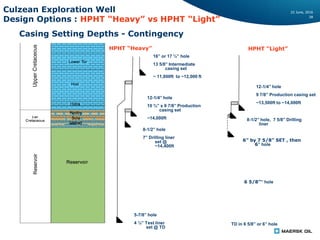

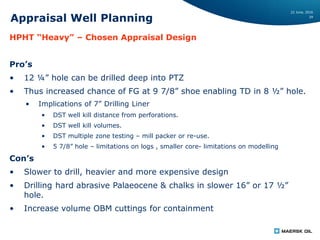

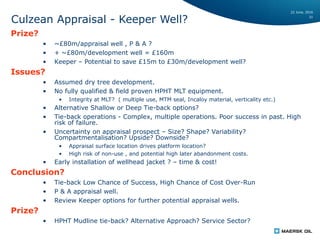

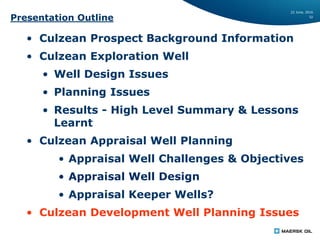

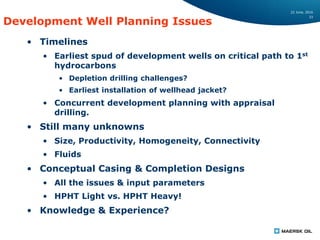

The document summarizes lessons learned from drilling Maersk Oil UK's first high-pressure, high-temperature (HPHT) exploration well at the Culzean prospect in the UK North Sea. Some key challenges included limited data from a prior offset well, high pressure and temperature conditions, and geological uncertainty. The exploration well objectives were to safely drill to total depth, penetrate all reservoirs, log and pressure test formations. It achieved total depth but encountered pressure and fracture gradient surprises. Planning is now underway for appraisal wells to further evaluate the prospect for potential development.