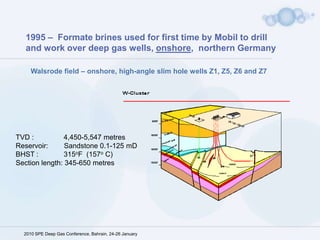

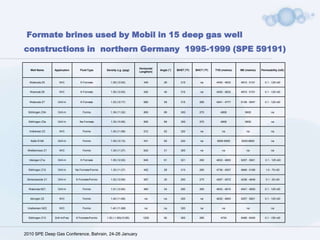

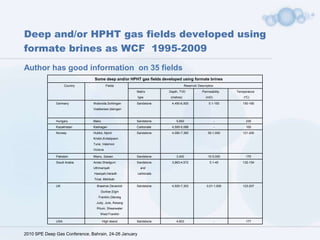

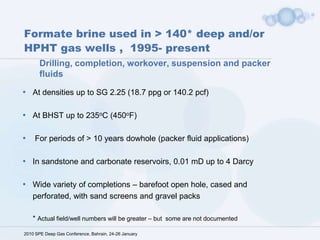

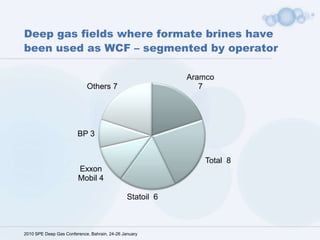

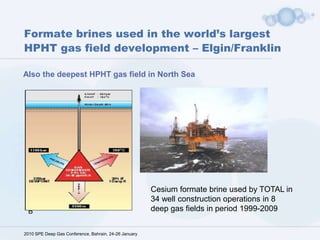

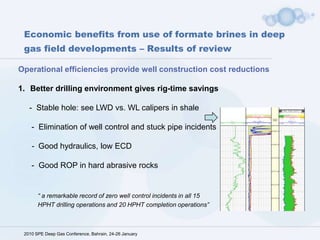

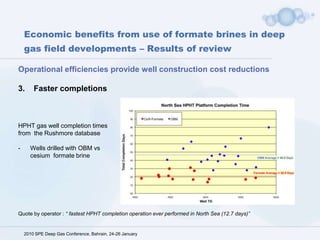

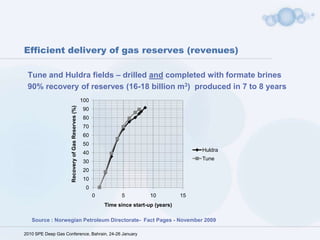

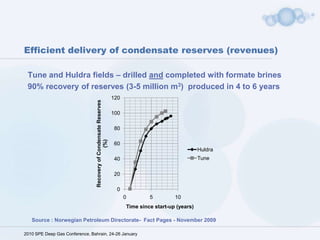

This document summarizes a presentation on the use of formate brines for deep gas field development projects. It finds that formate brines provide operational efficiencies over conventional drilling fluids by providing a more stable wellbore, faster tripping speeds, and fewer well control incidents. These efficiencies can reduce well construction costs and times. The document also finds that fields developed using only formate brines were able to recover 90% of reserves within 7-8 years, indicating formate brines may enable more efficient production.