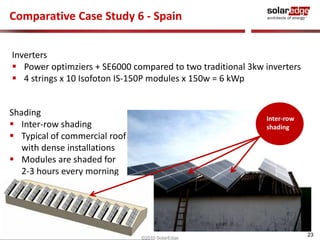

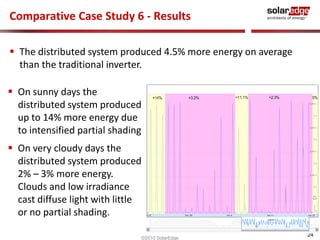

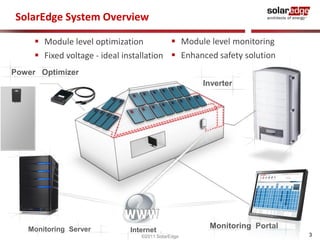

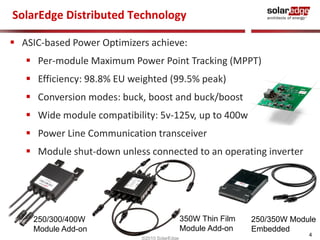

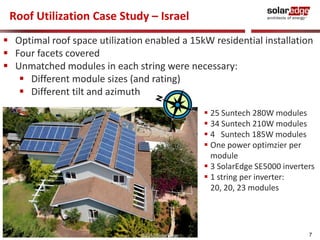

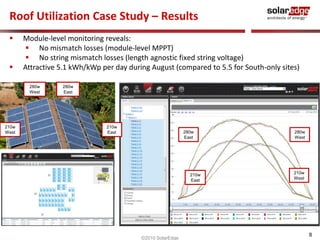

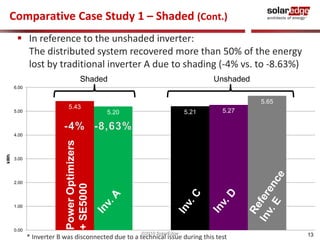

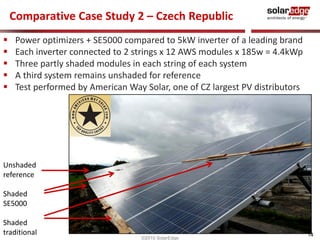

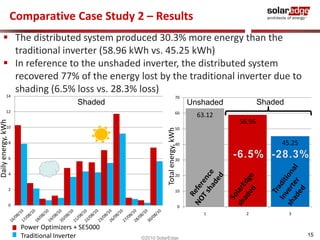

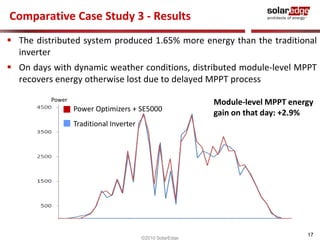

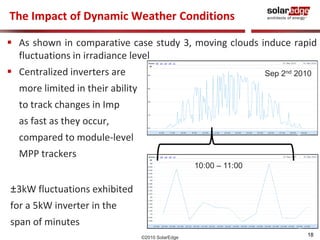

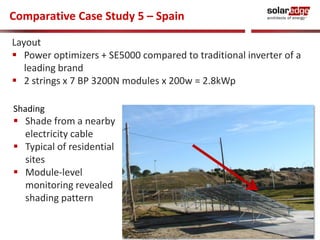

The document discusses the advantages of SolarEdge's distributed DC topology using power optimizers, highlighting reduced energy loss due to features like per-module maximum power point tracking (MPPT) and module-level monitoring. Case studies from various regions demonstrate that distributed systems outperform traditional inverters, especially in shaded conditions, providing higher energy production. Overall, the technology enables better roof utilization and greater energy efficiency across residential and commercial installations.

![20

Comparative Case Study 4 – Results

Introduction

The distributed system produced 4% - 8% more energy than the

traditional inverter on most days of the month

Distributed system production was lower on days with very low

irradiance, due to sizable self consumption of the prototype DSP

version of the unit, now replaced by an efficient ASIC

SolarEdge Daily Energy gain

vs. traditional inverter [%]

©2010 SolarEdge](https://image.slidesharecdn.com/how-much-energy-lost-from-partial-shading-141119212359-conversion-gate01/85/Optimizing-Commercial-Solar-PV-Systems-How-much-energy-lost-from-Partial-Shading-20-320.jpg)

![Traditional [kWh]

SolarEdge [kWh]

Weekly Energy

Gain [%]

22

Comparative Case Study 5 – Results

Accumulated Energy comparisons shows the distributed system

consistently produces 4% more energy than the traditional inverter

Energy Gain in [%]

©2010 SolarEdge](https://image.slidesharecdn.com/how-much-energy-lost-from-partial-shading-141119212359-conversion-gate01/85/Optimizing-Commercial-Solar-PV-Systems-How-much-energy-lost-from-Partial-Shading-22-320.jpg)