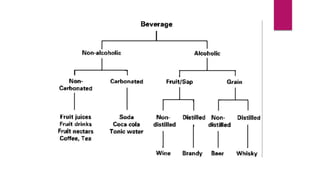

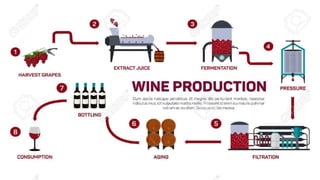

The document details the production processes of alcoholic beverages, primarily focusing on wine and beer. It describes the fermentation process, key ingredients such as Saccharomyces cerevisiae yeast, and stages of production including harvesting, crushing, fermentation, clarification, aging, and bottling. It also explores types of wines and the brewing process of beer, emphasizing the importance of each step for the quality of the final product.