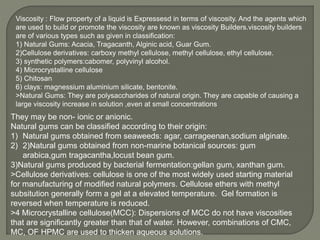

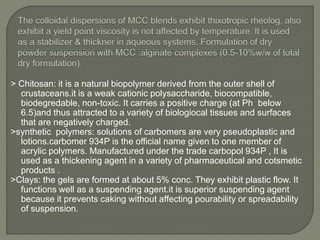

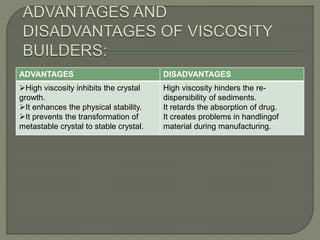

This document discusses viscosity builders, which are agents that increase the viscosity of liquids. It classifies and describes six main types of viscosity builders: natural gums, cellulose derivatives, microcrystalline cellulose, chitosan, synthetic polymers, and clays. Natural gums are polysaccharides that can greatly increase viscosity, even at low concentrations, and include gums from seaweeds and plants. Cellulose derivatives are modified forms of cellulose, such as methyl cellulose. Microcrystalline cellulose does not significantly increase viscosity on its own but is used in combinations. Chitosan is derived from crustacean shells. Synthetic polymers include carbomers. Clays form gels at 5% concentration and