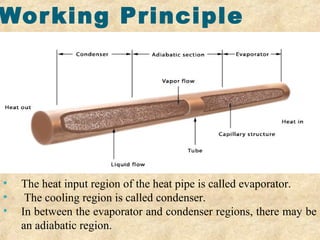

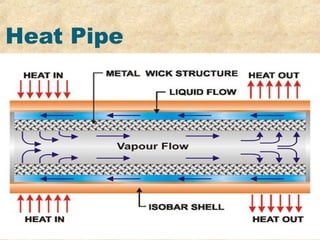

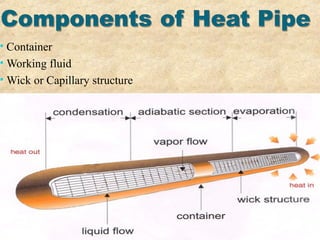

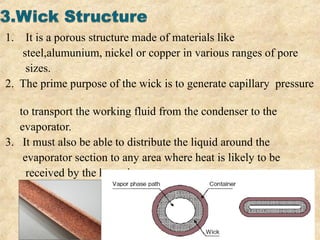

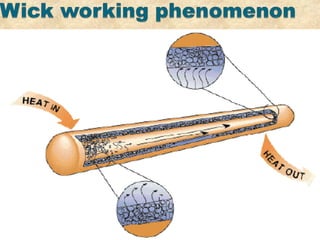

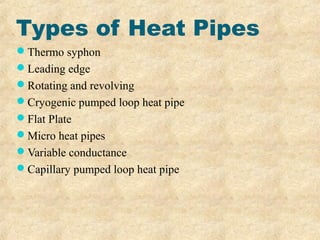

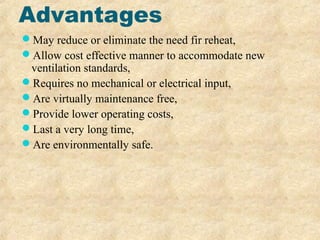

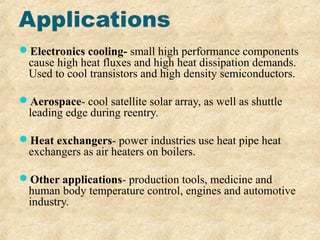

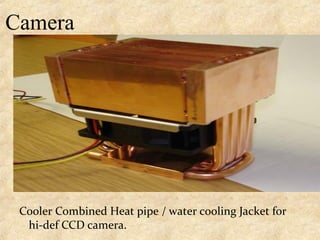

This document provides an overview of heat pipes, including their working principle, key components, types, advantages, and applications. A heat pipe transfers heat using an evaporation-condensation cycle within a sealed container consisting of a working fluid and capillary wick. Heat is absorbed at the evaporator section where the fluid evaporates, transferring heat through the vapor to the condenser section where it condenses, releasing heat and returning via the wick to the evaporator. Heat pipes can transfer heat very efficiently over long distances with minimal temperature difference due to the phase change process. Common applications include electronics cooling, aerospace systems, and industrial heat exchangers.