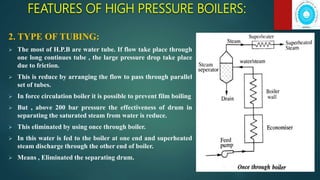

This document provides an introduction to high pressure boilers. It discusses the unique features of high pressure boilers such as forced water circulation, small diameter tubes, and higher steam pressures and temperatures. It then summarizes several types of high pressure boilers including La-Mont, Benson, Loeffler, and Schmidt-Hartmann boilers. It also discusses supercritical boilers, fluidized bed combustion systems, and methods for superheat control and corrosion prevention in boilers.