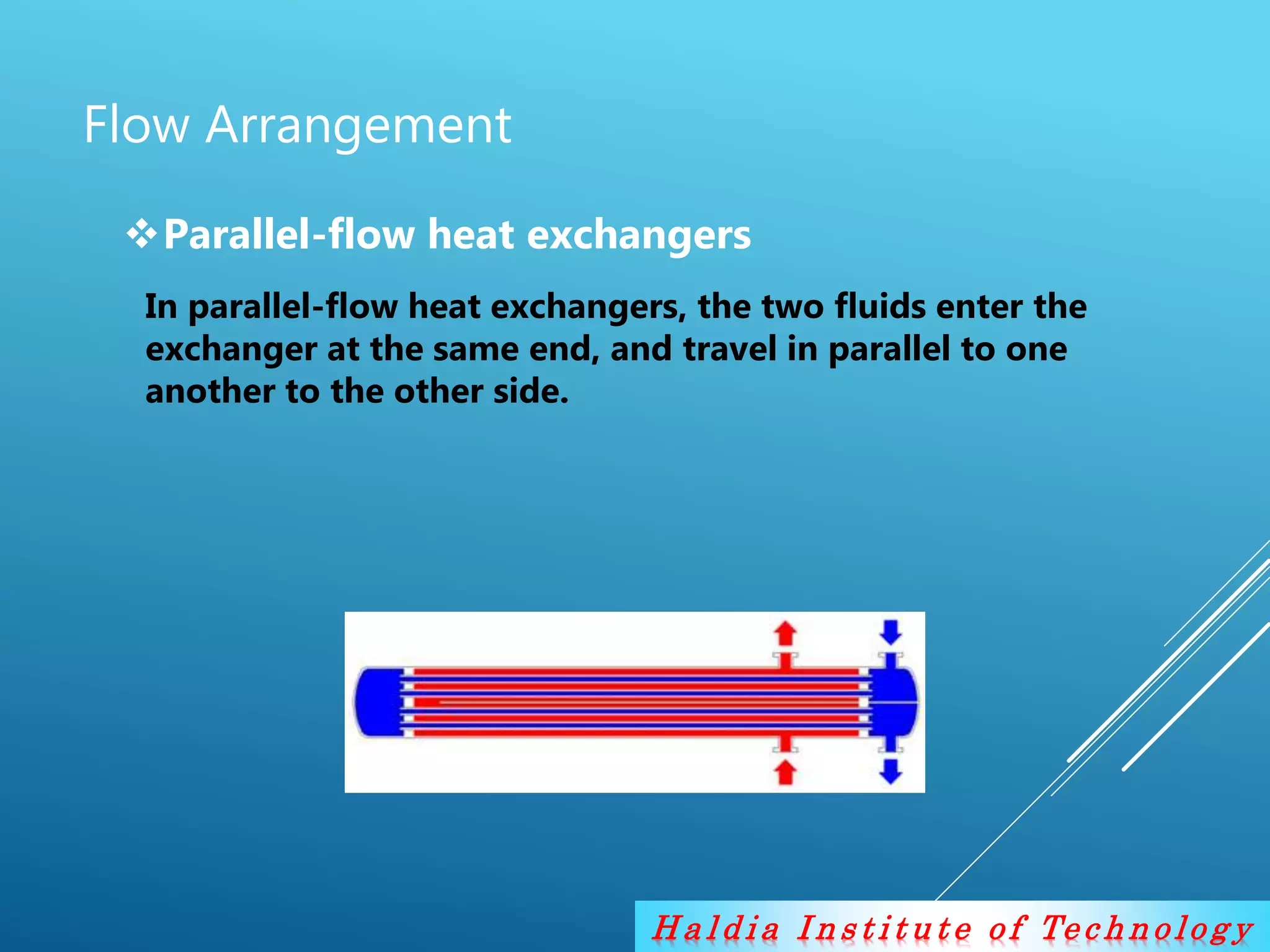

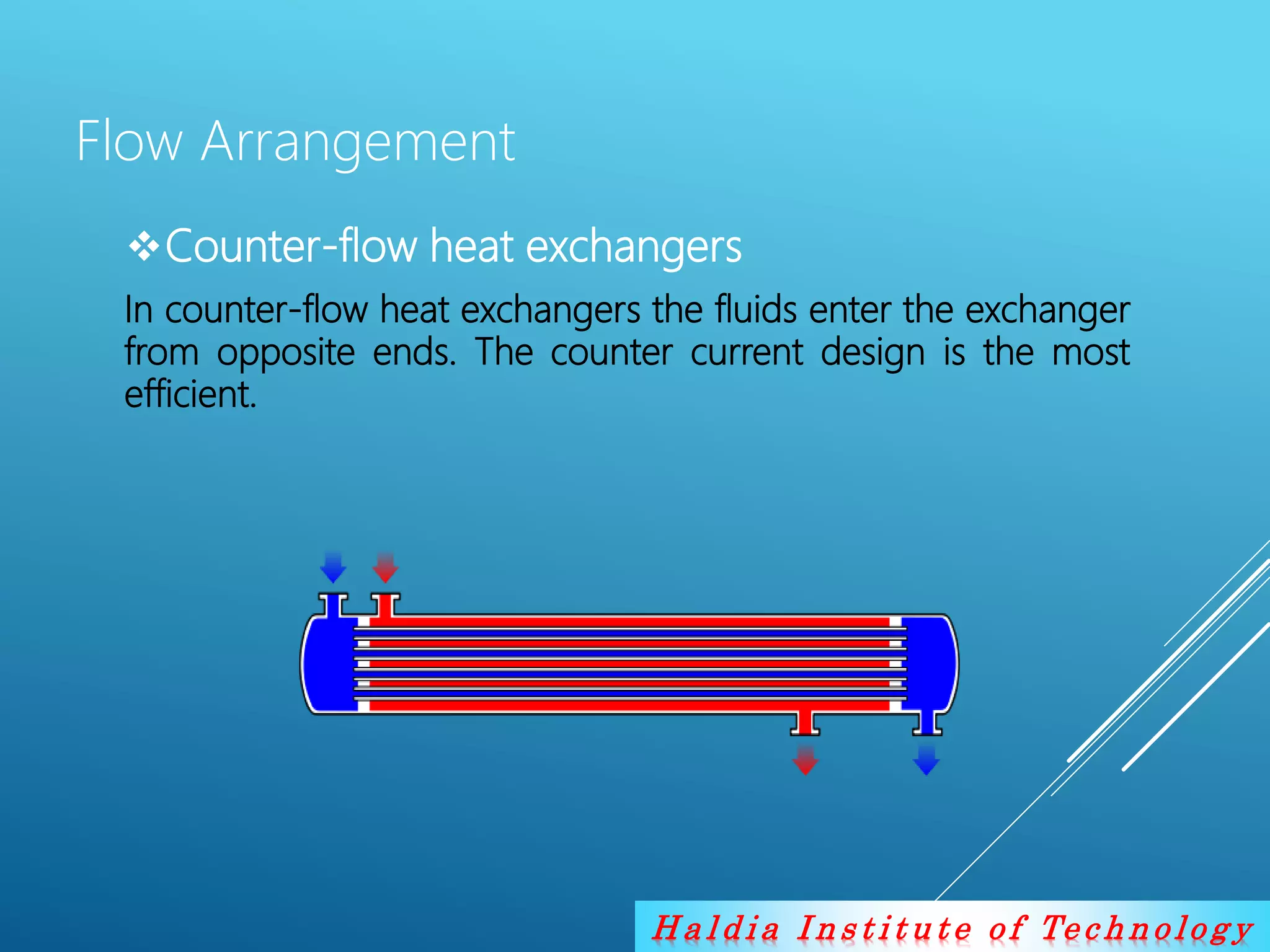

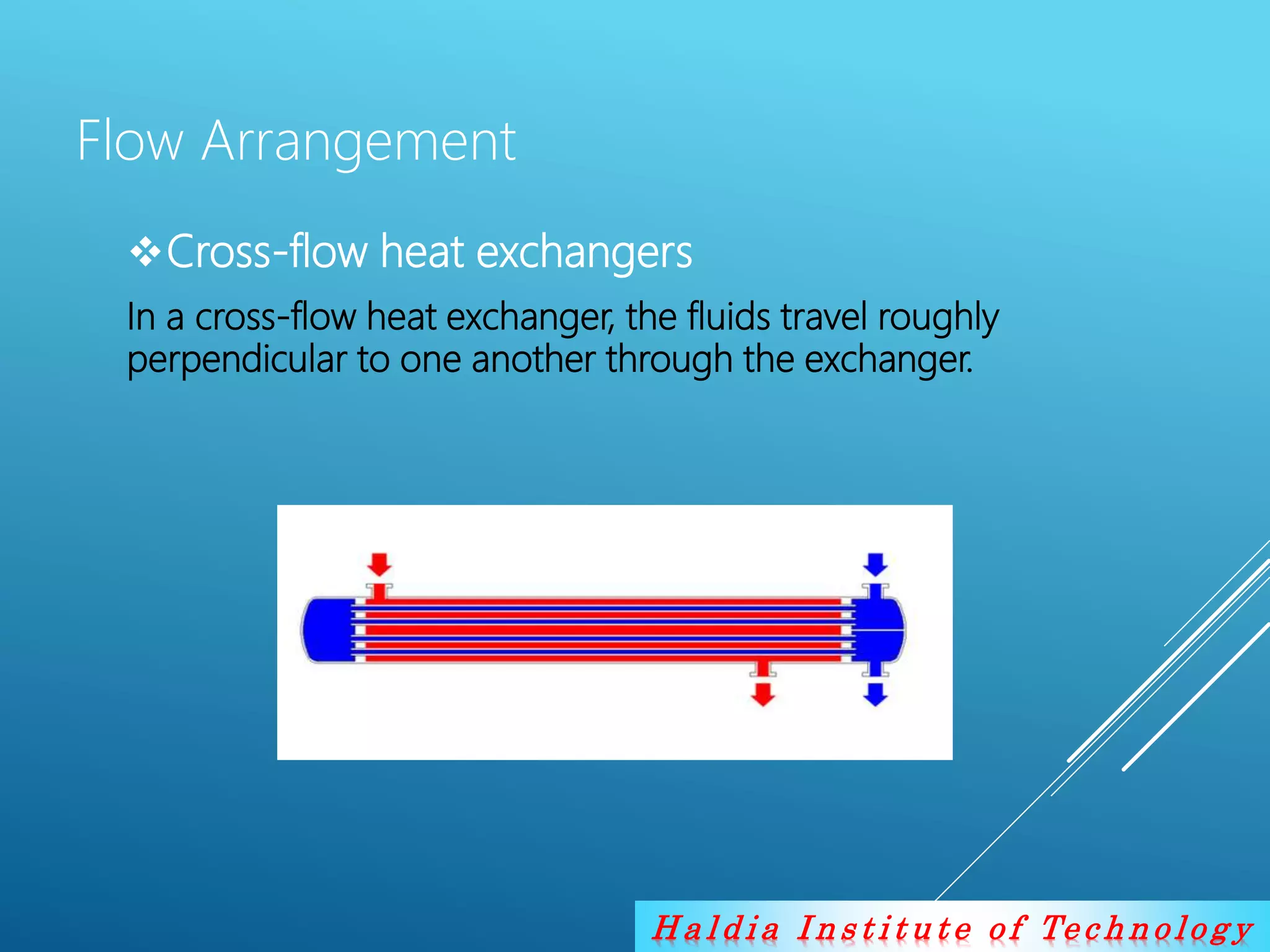

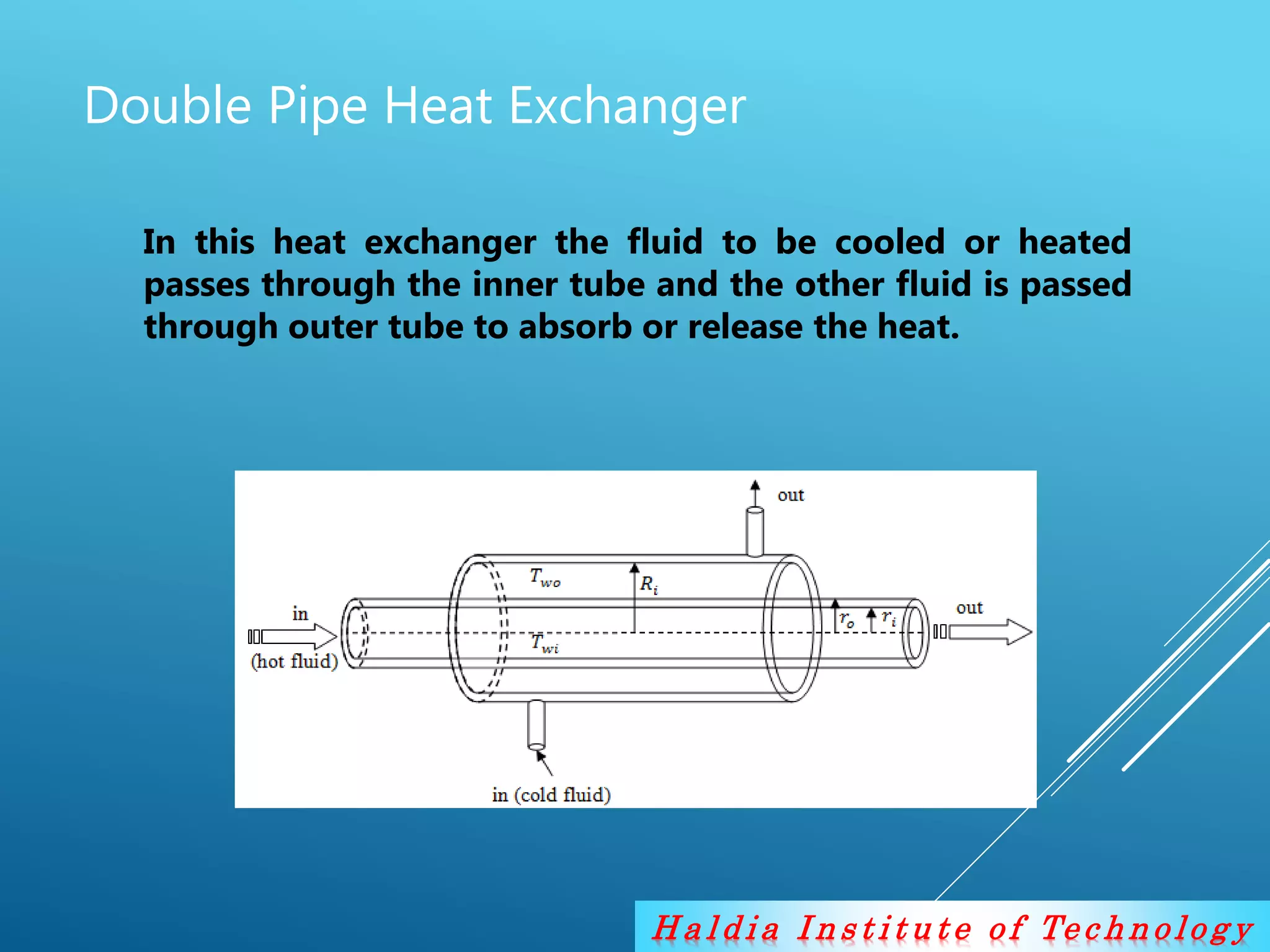

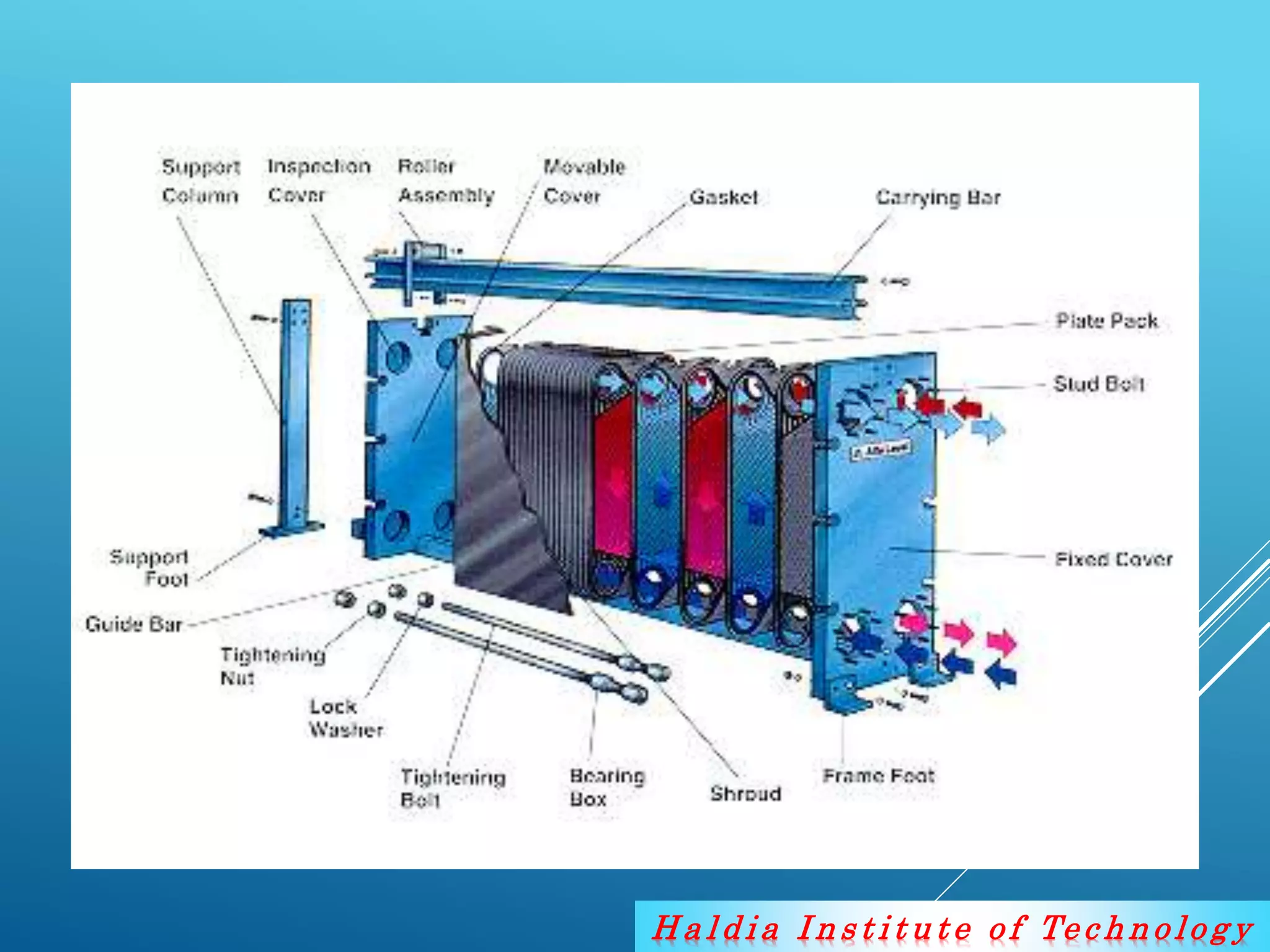

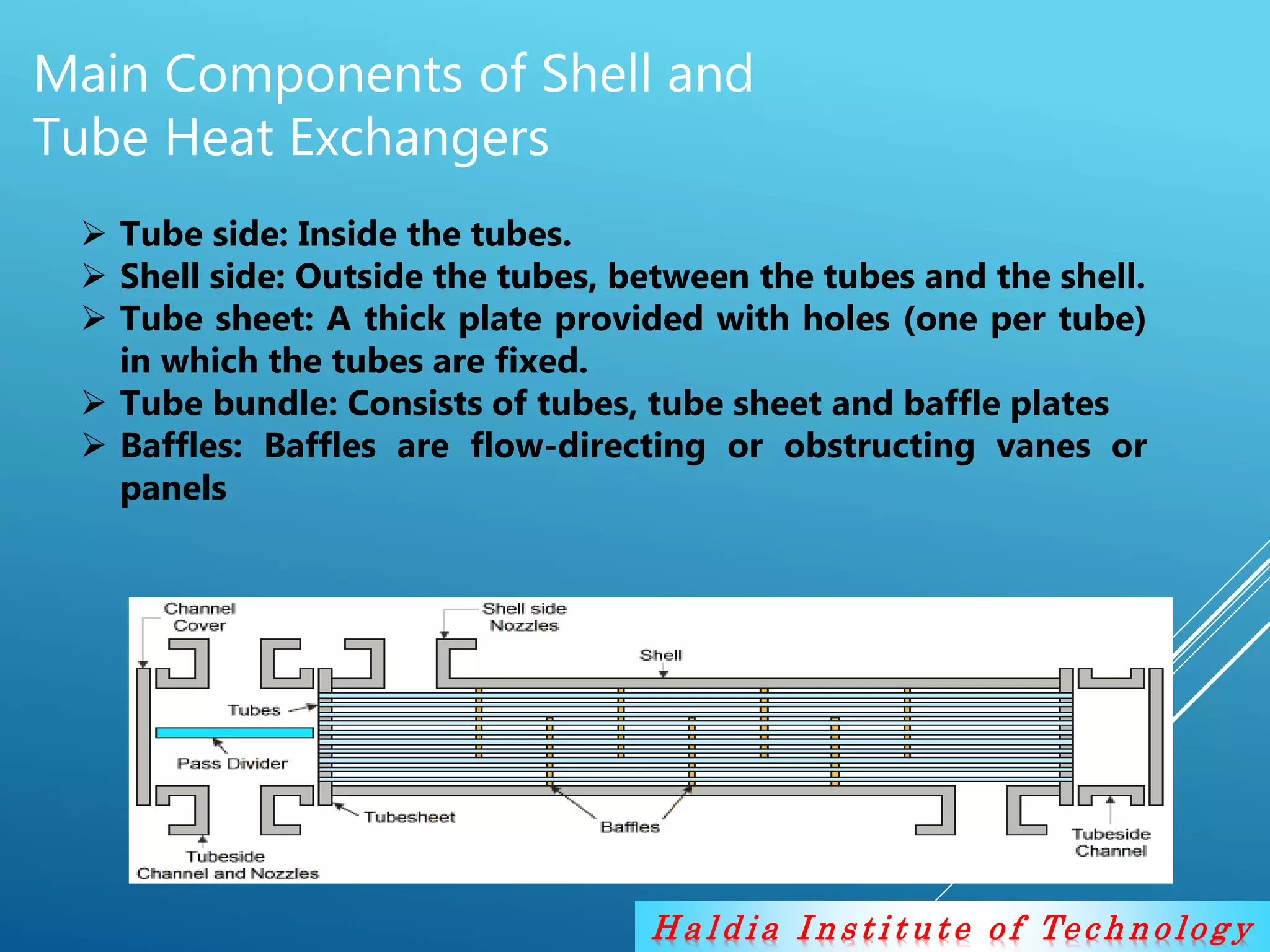

The document provides a comprehensive overview of heat exchangers, including their principles, types, and selection criteria. It explains various flow arrangements such as parallel-flow, counter-flow, and cross-flow, highlighting shell and tube heat exchangers as the most prevalent in industry. Additionally, the document emphasizes the importance of understanding different types for proper selection to ensure efficient performance.