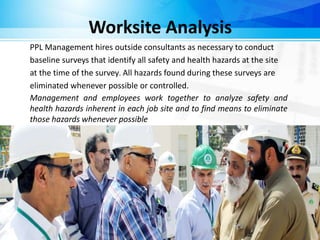

The document outlines various occupational health and safety policies and programs at Pakistan Petroleum Limited (PPL), including creating safe work environments, promoting health and safety awareness, investigating accidents, providing medical services and examinations for employees, monitoring occupational health hazards, and enforcing general safety precautions. PPL aims to ensure a healthy and safe work environment for employees and reduce accidents, injuries, and illnesses through these initiatives.

![On Site Medical Aid:

The On Site Medical Services Program is under the leadership of physicians, who are available to

respond to medical emergencies. First aid is available all the time from fire department. The

clinical laboratory is staffed by licensed medical technologists. Physical examinations are

done by contract physicians and [Company] physicians. The contract physicians are not

employees of the Company. Nurses are on duty from 7:30 a.m. until 5:00p.m on workdays.](https://image.slidesharecdn.com/finalhrm-160109195009/85/Health-and-Safety-Analysis-28-320.jpg)