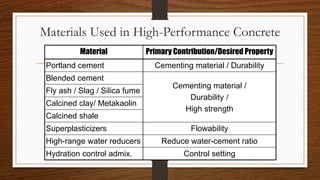

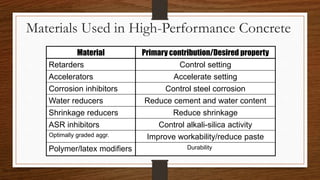

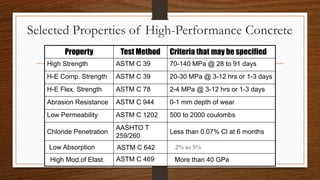

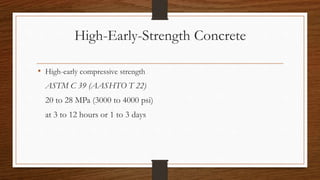

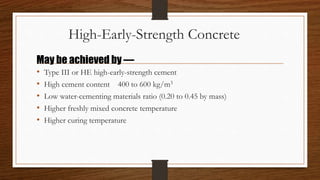

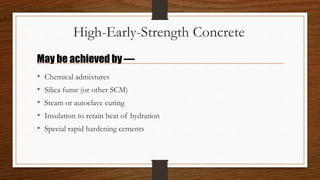

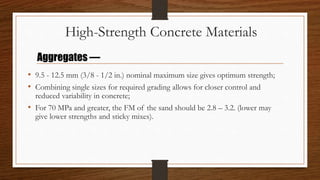

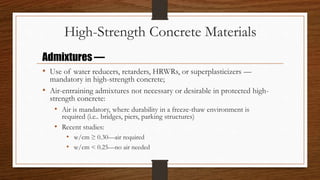

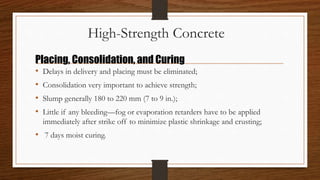

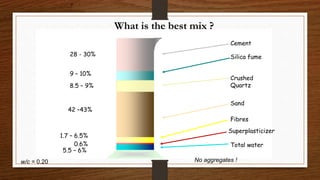

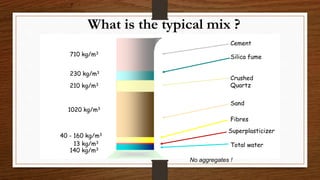

This document discusses materials and properties for high-performance concrete used in a high-rise building project. It lists nine group members assigned to the preliminary design project aiming to create sustainable and durable concrete using synergistic effects of supplementary cementitious materials. The document then discusses characteristics, materials, properties and considerations for developing high-performance, high-strength, and high-early-strength concrete. Typical mix designs are provided as examples.