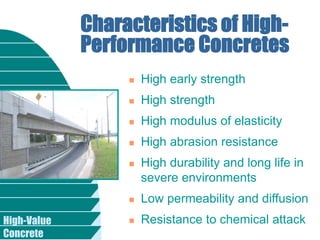

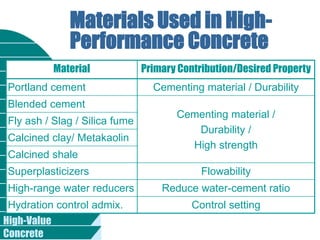

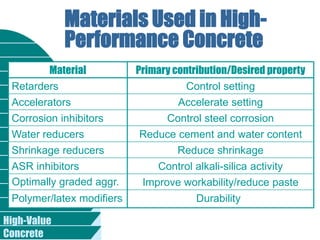

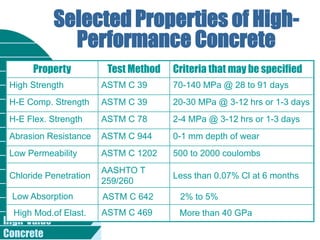

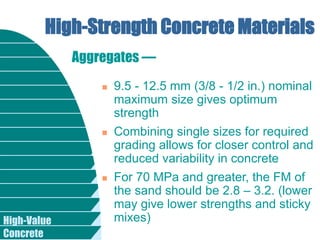

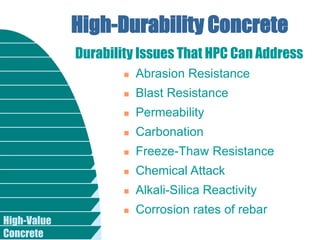

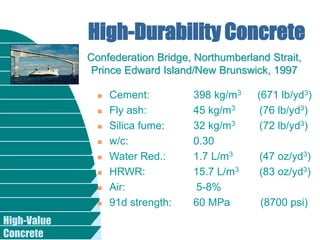

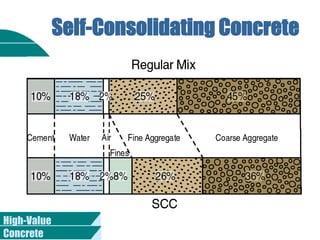

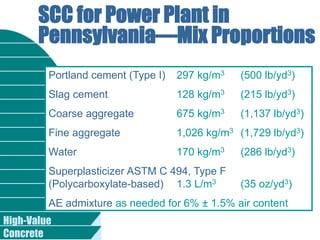

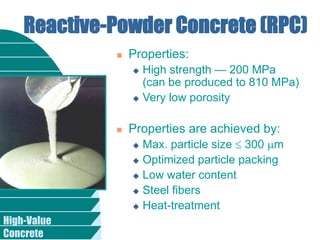

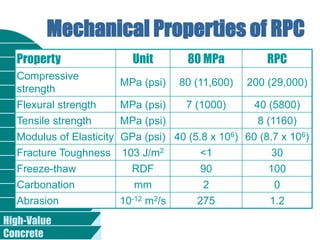

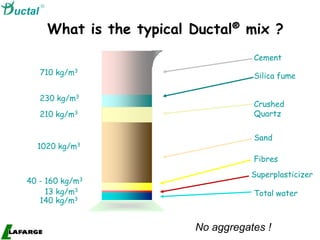

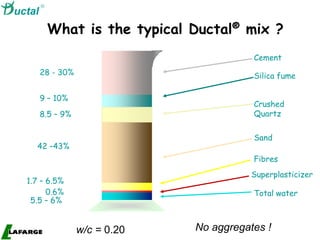

This document provides an overview of high-performance or high-value concrete, including characteristics, materials used, and properties. It discusses several types of high-performance concrete such as high-early strength concrete, high-strength concrete, high-durability concrete, self-consolidating concrete, and reactive powder concrete. For each type, it outlines key properties and characteristics as well as typical mix designs and materials used to achieve those properties.