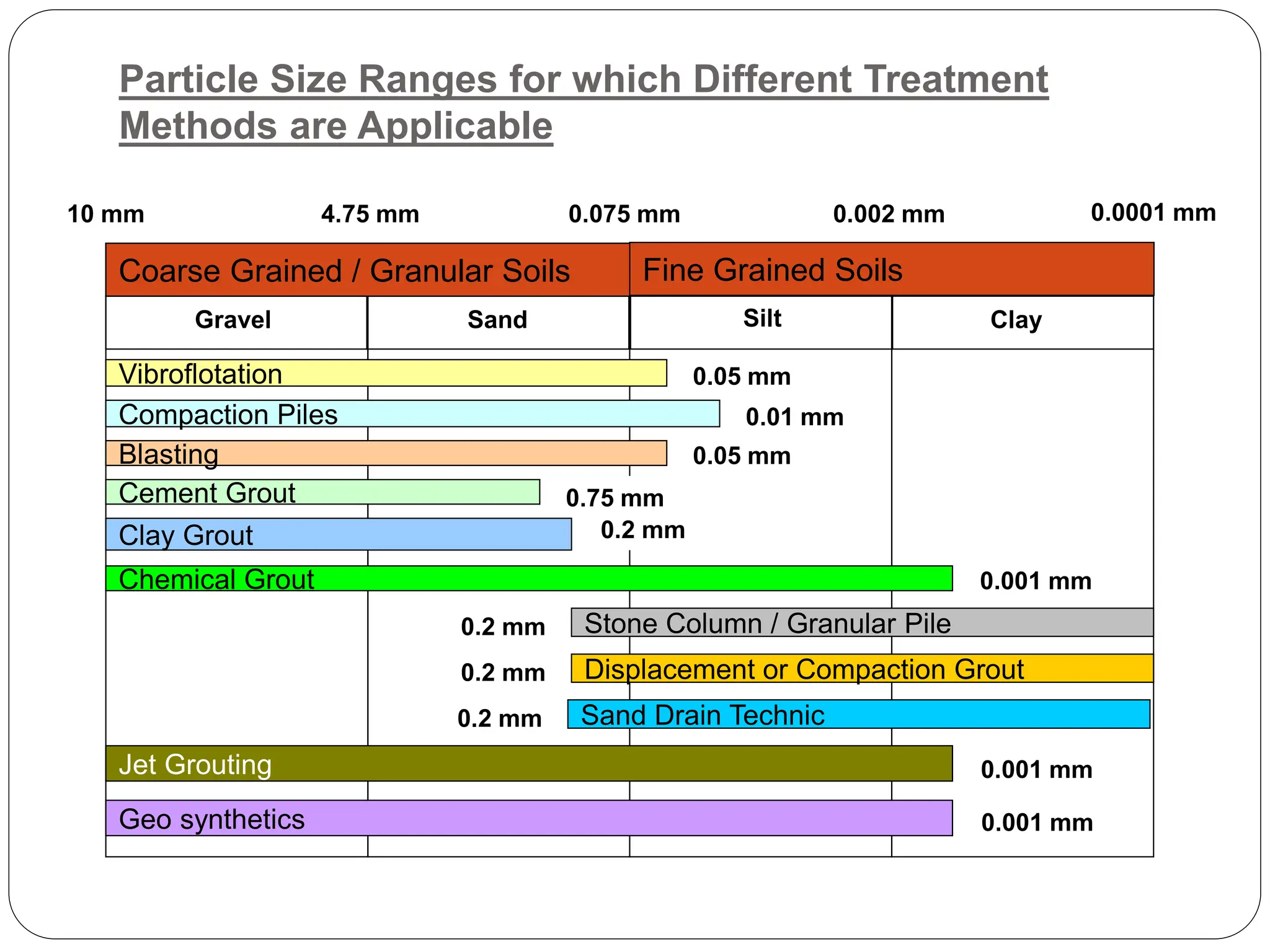

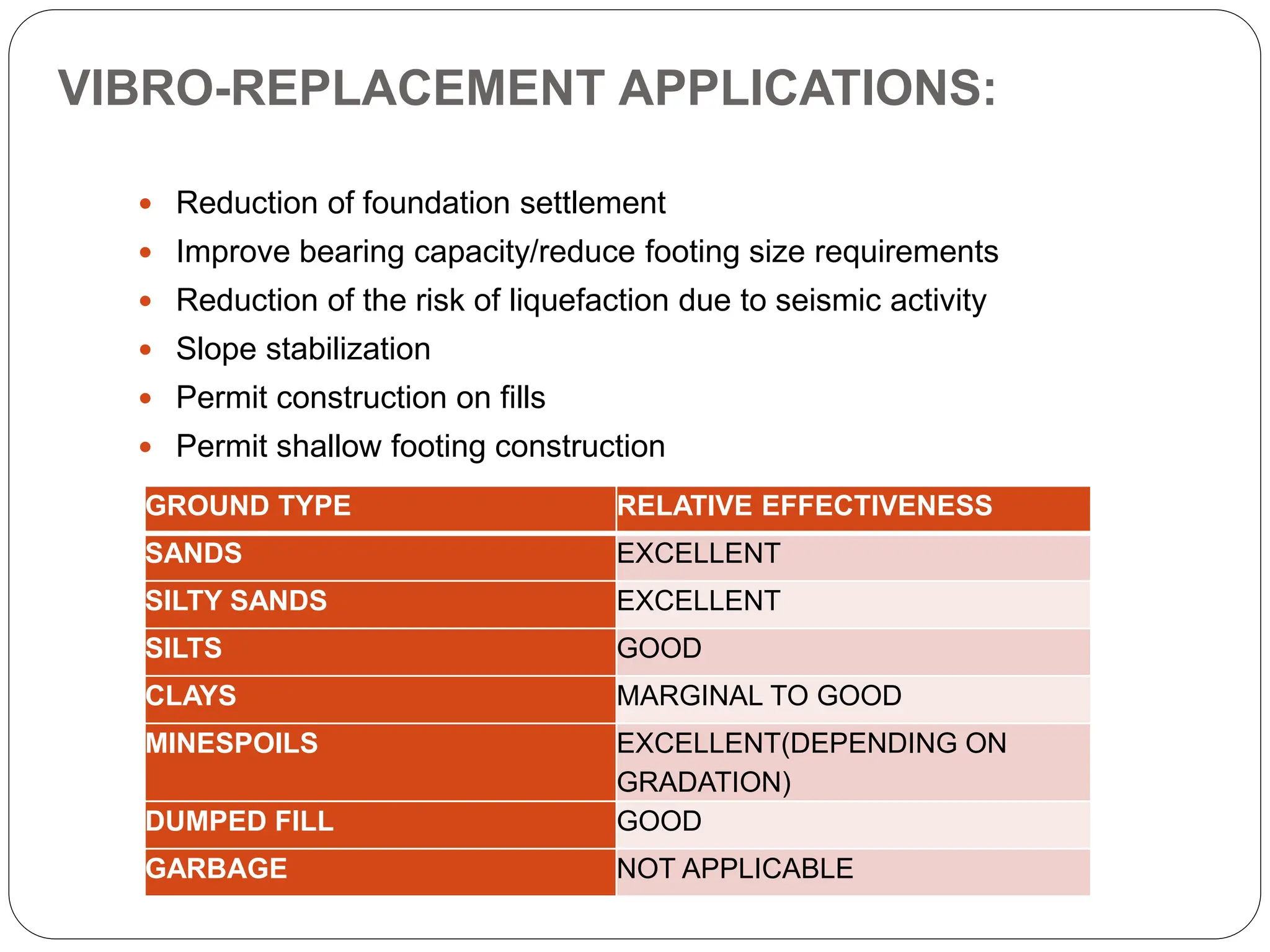

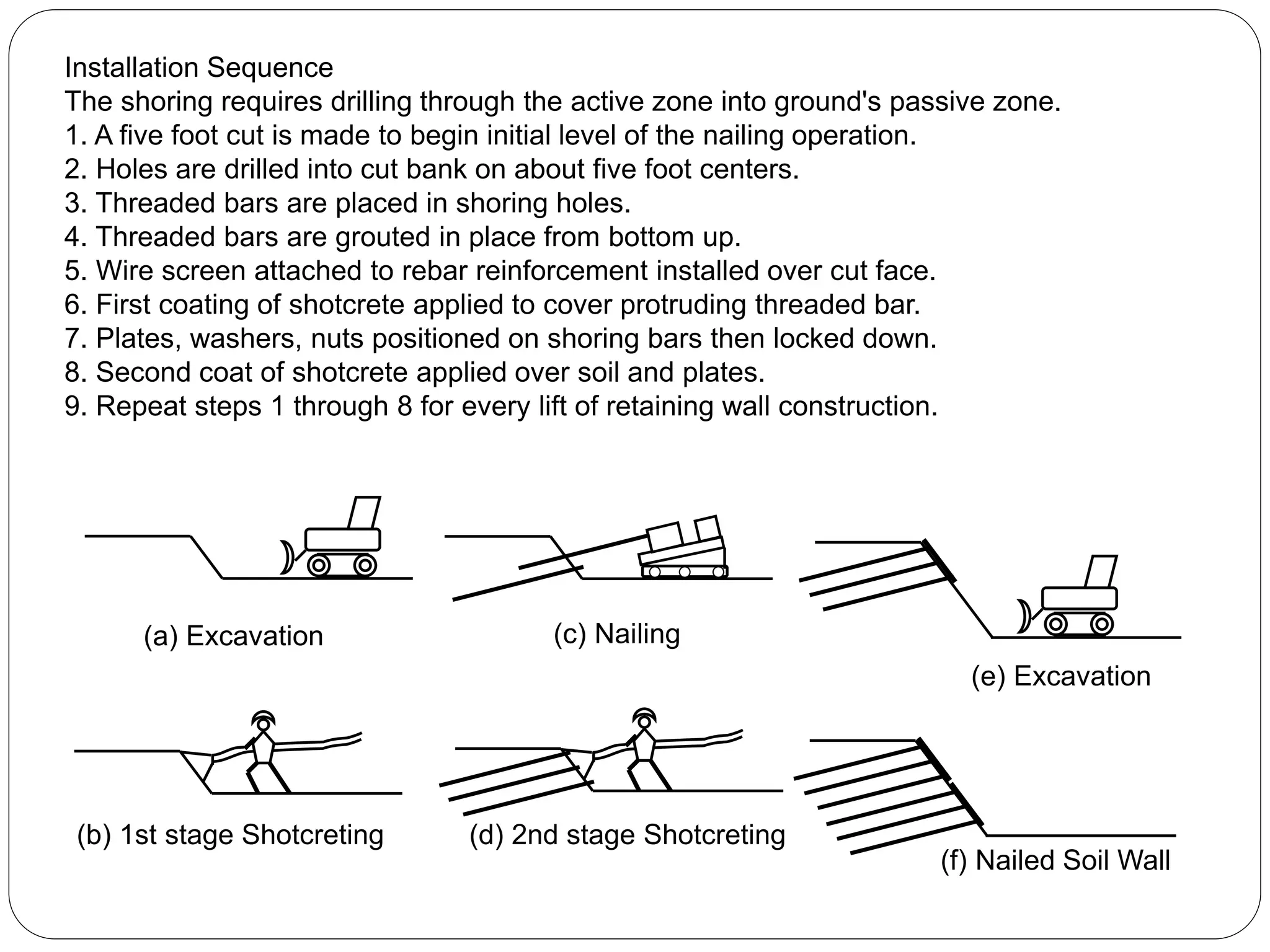

The document discusses various soil improvement techniques including vibro-compaction, vibro-replacement stone columns, vacuum consolidation, preloading, heating, ground freezing, mechanically stabilized earth structures, soil nailing, and micro piles. It provides details on the principles, applications, and considerations for each technique.