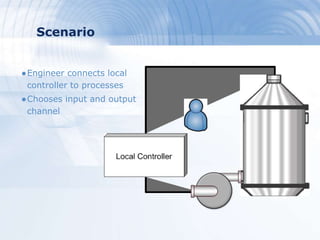

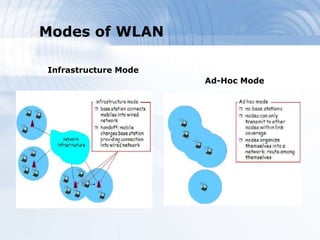

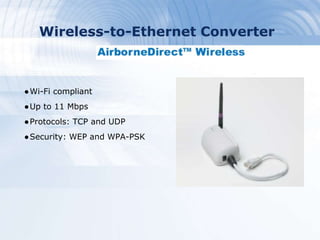

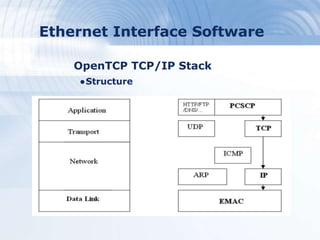

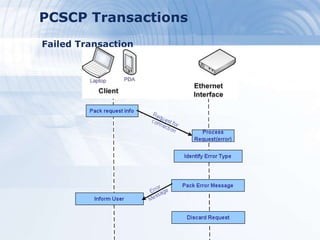

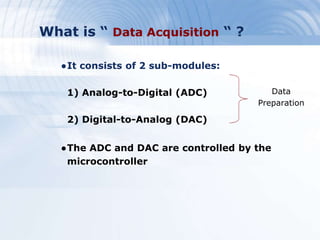

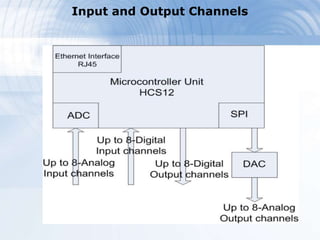

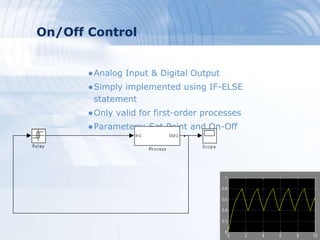

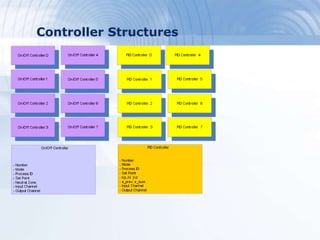

The document discusses a project to implement a distributed process control system with wireless accessibility. It describes the Process Control Studio software, which allows designing and monitoring industrial processes on a laptop or PDA. The software includes features like alarming, data storage, and a mobile edition. Wireless connectivity is provided via WiFi, and an Ethernet controller allows interfacing with local measurements and controls. The controller performs data acquisition from analog and digital sensors using an ADC and can control actuators with a DAC. It also implements on-off and PID control algorithms using a microcontroller. The goal is to provide localized wireless monitoring and control of industrial processes.